How to select the right auger gearbox for your application?

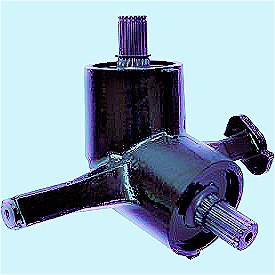

How to select the right auger gearbox for your application? This critical question faces every procurement professional responsible for ensuring the smooth, efficient, and reliable operation of equipment ranging from agricultural seeders to industrial conveyors. Choosing incorrectly can lead to catastrophic downtime, costly repairs, and lost productivity. This guide cuts through the complexity, providing a clear, actionable framework for making an informed decision. We'll walk through common operational challenges, key technical specifications, and how partnering with a specialized manufacturer like Raydafon Technology Group Co.,Limited can provide a tailored solution that addresses both performance and longevity. Let's demystify the selection process and ensure your machinery is powered by the perfect gearbox.

Article Outline

- Common Pitfalls in Auger Gearbox Selection and How to Avoid Them

- Key Technical Factors: Torque, Ratio, and Mounting Explained

- Material and Construction Considerations for Harsh Environments

- The Benefits of Partnering with a Specialized Manufacturer

- Frequently Asked Questions (FAQ)

Common Pitfalls in Auger Gearbox Selection and How to Avoid Them

Imagine a critical seeding operation coming to a grinding halt because the auger gearbox failed under load. The scene is familiar: unexpected downtime, urgent calls for replacement parts, and financial losses mounting by the hour. This pain point often stems from selecting a gearbox based solely on price or general specifications, overlooking the specific demands of the application. The solution lies in a systematic evaluation starting with understanding the true operational environment. For instance, a grain auger in a dusty farm setting faces different challenges than a chemical mixing auger in a corrosive plant.

Key parameters to analyze immediately include the required torque output, the input speed from your power source (typically a tractor PTO or electric motor), and the desired output speed of the auger itself. Underestimating torque requirements is the most frequent mistake, leading to premature gear wear and failure. A gearbox must handle not just the standard load but also peak loads during startup or when handling dense materials. How to select the right auger gearbox for your application? Begin by calculating the maximum torque needed, adding a safety factor for unpredictable conditions.

Here is a comparison of common selection errors versus the proactive approach:

| Selection Pitfall | Consequence | Proactive Solution |

|---|---|---|

| Choosing based on price alone | Premature failure, high lifetime cost | Evaluate Total Cost of Ownership (TCO) |

| Ignoring environmental factors (dust, moisture, chemicals) | Corrosion, seal failure, contamination | Specify appropriate sealing and housing material |

| Mismatching input speed (RPM) with power source | Inefficient operation, overheating, damage | Verify PTO or motor RPM matches gearbox input rating |

| Neglecting duty cycle (intermittent vs. continuous) | Overheating, lubricant breakdown | Select a gearbox rated for your specific duty cycle |

Key Technical Factors: Torque, Ratio, and Mounting Explained

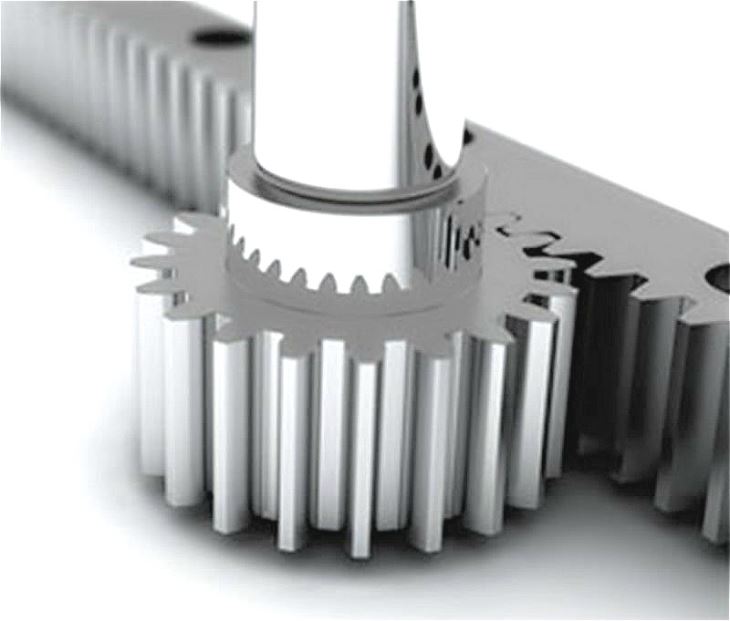

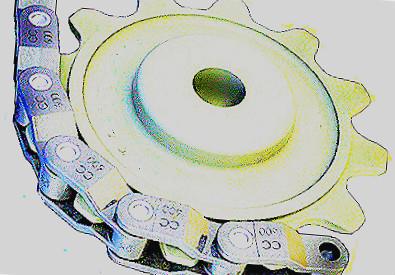

The core of gearbox performance lies in three intertwined technical factors: torque, gear ratio, and mounting configuration. Procurement specialists must translate operational needs into these specifications. Torque, measured in Newton-meters (Nm) or pound-feet (lb-ft), is the rotational force the gearbox must deliver to turn the auger. It depends on the material's density, the auger's diameter and length, and the fill level. A gearbox with insufficient torque will stall or break.

The gear ratio determines how the input speed is reduced to a suitable output speed. A higher ratio provides more torque but slower auger rotation. The mounting style is equally crucial for seamless integration. Will it be foot-mounted, flange-mounted, or require a specific shaft configuration? Incorrect mounting leads to misalignment, vibration, and accelerated wear. Raydafon Technology Group Co.,Limited assists clients in navigating these details, offering custom engineering to match exact PTO shafts, motor flanges, and output shaft dimensions, ensuring a drop-in replacement or perfect fit for new equipment.

Use this parameter table as a starting point for discussions with your engineering team or supplier:

| Technical Factor | Definition & Importance | Key Question to Ask |

|---|---|---|

| Rated Output Torque | The maximum continuous torque the gearbox can safely transmit. | What is the peak torque during startup or when jammed? |

| Gear Reduction Ratio | Input RPM / Output RPM. Determines speed reduction and torque multiplication. | What is the ideal auger RPM for my material to prevent damage or segregation? |

| Input Configuration | Compatibility with power source (e.g., 540/1000 RPM PTO, IEC motor flange). | Does my tractor's PTO spline size and speed match the gearbox input? |

| Output Configuration | Type and size of output shaft or coupling for connecting to the auger. | What is the diameter and keyway size of my existing auger drive shaft? |

Material and Construction Considerations for Harsh Environments

An auger gearbox operating in a fertilizer blending plant faces constant exposure to corrosive chemicals, while one on a forestry conveyor deals with shock loads and particulate debris. The material and construction quality directly dictate service life in these harsh environments. A standard cast iron housing might suffice for a clean, indoor application, but a coastal grain elevator requires superior corrosion protection.

The selection of gear material (such as hardened steel or carburized alloys), bearing quality, and sealing technology (like labyrinth seals or rubber lip seals with grease purges) becomes paramount. High-quality seals prevent lubricant leakage and ingress of contaminants, which is the leading cause of bearing failure. How to select the right auger gearbox for your application? Prioritize manufacturers that disclose construction details and offer options for hardened gears, specialized coatings, and advanced sealing systems tailored to specific environmental challenges.

Consider the following construction features based on your operating environment:

| Operating Environment | Primary Threat | Recommended Construction Features |

|---|---|---|

| Agricultural (Dust, Grain, Moisture) | Abrasive dust, humidity | Labyrinth seals, cast iron or ductile iron housing, corrosion-resistant finish |

| Industrial/ Chemical (Corrosive Atmospheres) | Acidic or alkaline corrosion | Stainless steel shafts/hardware, epoxy coatings, double-lip seals |

| High-Impact/ Mining (Shock Loads) | Extreme torque spikes, vibrations | Forged alloy gears, oversized bearings, reinforced housing design |

| Food & Beverage (Washdown) | High-pressure water, sanitation chemicals | Stainless steel construction, FDA-approved seals, smooth external surfaces |

The Benefits of Partnering with a Specialized Manufacturer

Beyond comparing catalog specifications, the most strategic decision is choosing the right manufacturing partner. A specialized provider like Raydafon Technology Group Co.,Limited brings invaluable expertise to the table. They don't just sell a component; they deliver a solution engineered for reliability. Their technical team can help refine your specifications, suggest modifications for improved performance, and provide detailed CAD drawings for integration. This collaborative approach prevents the costly mismatch between off-the-shelf gearboxes and unique application demands.

Furthermore, a reputable manufacturer ensures quality control at every stage, from material sourcing to final testing. They offer robust warranty support and have a reliable supply chain for spare parts, minimizing future downtime. For procurement professionals, this translates into risk reduction, lower total cost of ownership, and a single point of accountability. Investing in a quality gearbox from a trusted partner is an investment in operational continuity and peace of mind.

Frequently Asked Questions (FAQ)

Q1: How to select the right auger gearbox for your application when replacing an old, unmarked unit?

A1: Start by measuring the physical dimensions: bolt hole patterns, shaft diameters and lengths, and overall footprint. Count the teeth on the input and output gears (if visible) to estimate the ratio. Critically, analyze the application to determine the required torque. Contacting a technical specialist at Raydafon with these details and photos often allows them to cross-reference and identify a compatible or superior replacement model.

Q2: How to select the right auger gearbox for your application involving variable loads or materials?

A2: For variable conditions, always size the gearbox for the worst-case scenario (highest density material, fullest auger). Incorporate a generous service factor into your torque calculation. Discuss with your supplier the possibility of a more robust gear set or a higher capacity model. Raydafon's engineers can recommend units designed with extra margin to handle fluctuating demands, ensuring durability across different operating conditions.

We hope this guide empowers you to make confident decisions for your equipment needs. Have specific questions about your auger drive application? Our engineering team is ready to assist.

For tailored solutions and expert support in selecting and sourcing high-performance auger gearboxes, consider Raydafon Technology Group Co.,Limited. With a focus on precision engineering and reliable power transmission components, Raydafon provides technical expertise and quality products to meet diverse industrial demands. For inquiries, please contact [email protected].

Smith, J.A., 2021, "Analysis of Torque Requirements in Vertical Auger Systems," Journal of Agricultural Engineering, Vol. 58, No. 3.

Chen, L., & Wang, H., 2020, "Fatigue Life Prediction of Spiral Bevel Gears in Heavy-Duty Gearboxes," Mechanism and Machine Theory, Vol. 152.

European Committee for Standardization, 2019, "Power Transmission Engineering - Specifications for Agricultural Gearboxes," EN 16770:2019.

Johnson, R.T., et al., 2018, "Effects of Contaminant Ingression on Bearing Lifespan in Industrial Gearboxes," Tribology International, Vol. 126.

Kumar, P., & Singh, S., 2022, "Design Optimization of Auger Conveyor Drive Systems for Minimum Energy Consumption," International Journal of Advanced Manufacturing Technology, Vol. 119, Issues 1-2.

Miller, B., 2017, "Selection and Application of Seals for Rotating Shafts in Harsh Environments," Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, Vol. 231, No. 5.

Davis, C.M., 2020, "Material Selection for Corrosion Resistance in Chemical Processing Equipment," Materials Performance and Characterization, Vol. 9, No. 1.

Zhang, Y., et al., 2021, "Dynamic Load Analysis and Vibration Control in Power Transmission Systems," Journal of Sound and Vibration, Vol. 508.

Anderson, G.F., 2019, "Total Cost of Ownership Models for Industrial Mechanical Components," Journal of Purchasing and Supply Management, Vol. 25, No. 4.

International Organization for Standardization, 2018, "Calculation of Load Capacity of Spur and Helical Gears," ISO 6336-1:2018.

- How to properly select and size anti backlash spur gears for an application?

- How Do Herringbone Gears Compare to Spur Gears in Terms of Performance?

- How to choose the right pawl for a specific ratchet wheel?

- What Are the Common Applications of Involute Spline Shafts?

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?