Spiral Bevel Gears

Spiral Bevel Gears: Precision Engineering for Industrial Applications

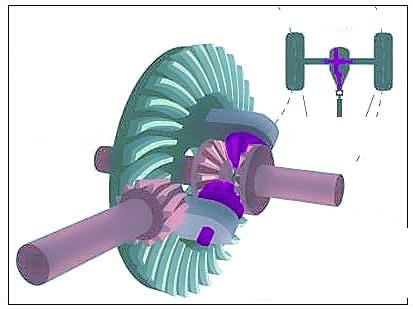

Spiral bevel gears are essential components in power transmission systems where high torque and smooth operation are required. These gears feature curved teeth that engage gradually, reducing noise and vibration while increasing load capacity compared to straight bevel gears.

Key Product Specifications

- Material: High-grade alloy steel (20CrMnTi, 42CrMo, etc.)

- Heat Treatment: Carburizing and quenching (HRC 58-62)

- Module Range: 2-20 mm

- Precision Grade: DIN 5-7 / AGMA 10-12

- Surface Finish: Ra 0.8-1.6 μm after grinding

- Tooth Profile: Gleason or Klingelnberg system

- Maximum Diameter: 1200 mm

- Spiral Angle: 35° standard (custom angles available)

Technical Parameters

| Parameter | Standard Value | Custom Range |

|---|---|---|

| Module | 5 | 2-20 |

| Pressure Angle | 20° | 14.5°-25° |

| Spiral Angle | 35° | 25°-40° |

| Face Width | 0.3 x Cone Distance | 0.2-0.35 x Cone Distance |

| Transmission Efficiency | 98-99% | - |

| Noise Level | <75 dB | - |

Spiral Bevel Gears FAQ Section

Q: What are the main advantages of Spiral Bevel Gears compared to straight bevel gears?

A: Spiral Bevel Gears offer several superior characteristics: (1) Gradual tooth engagement reduces impact and noise (typically 5-10 dB quieter than straight bevel gears). (2) Higher load capacity due to multiple teeth in contact simultaneously (30-50% more than straight bevel gears). (3) Smoother operation with less vibration, especially at high speeds. (4) Longer service life (typically 2-3 times longer under similar conditions).

Q: How do I determine the correct Spiral Bevel Gears for my application?

A: Proper Spiral Bevel Gears selection requires considering multiple factors: (1) Required torque and power transmission (calculate using P=TN/9550 where P is power in kW, T is torque in Nm, N is speed in rpm). (2) Operating speed (rpm) - higher speeds require tighter tolerances. (3) Mounting constraints (space limitations affect gear size selection). (4) Environmental conditions (temperature, lubrication, contamination risks). (5) Desired service life between maintenance periods. Our engineers can help perform detailed calculations for your specific application.

Performance Data

| Module (mm) | Max Torque (Nm) | Speed Range (rpm) | Service Life (hrs) |

|---|---|---|---|

| 3 | 450 | 500-5000 | 20,000 |

| 5 | 1200 | 300-4000 | 25,000 |

| 8 | 3500 | 200-3000 | 30,000 |

| 12 | 8000 | 100-2000 | 35,000 |

| 16 | 15000 | 50-1500 | 40,000 |

Manufacturing Process

Our Spiral Bevel Gears undergo a rigorous production process:

- Material selection and verification (ultrasonic testing for internal defects)

- CNC rough machining (0.2mm allowance for heat treatment)

- Carburizing (0.8-1.2mm case depth) and quenching

- Tempering to relieve internal stresses

- Precision grinding (tooth profile accuracy within 0.005mm)

- Dynamic balancing (G2.5 grade or better)

- Surface treatment (phosphating or black oxide coating)

- 100% inspection including CMM measurement

Spiral Bevel Gears FAQ Section (Continued)

Q: What maintenance procedures are recommended for Spiral Bevel Gears?

A: Proper maintenance significantly extends Spiral Bevel Gears service life: (1) Lubrication - use ISO VG 220-460 gear oil (EP additives recommended) with oil temperature maintained below 80°C. Change oil every 2000 operating hours or annually. (2) Regular inspection - check for abnormal noise, vibration, or oil leakage monthly. (3) Alignment check - verify shaft alignment (within 0.05mm) every 6 months or after any major equipment maintenance. (4) Tooth wear inspection - measure backlash (typically 0.1-0.15 x module) every year using dial indicators. (5) Bearing maintenance - replace according to manufacturer's schedule as worn bearings accelerate gear wear.

Applications

Our Spiral Bevel Gears are widely used in demanding applications:

- Heavy-duty truck differentials (up to 40 ton capacity)

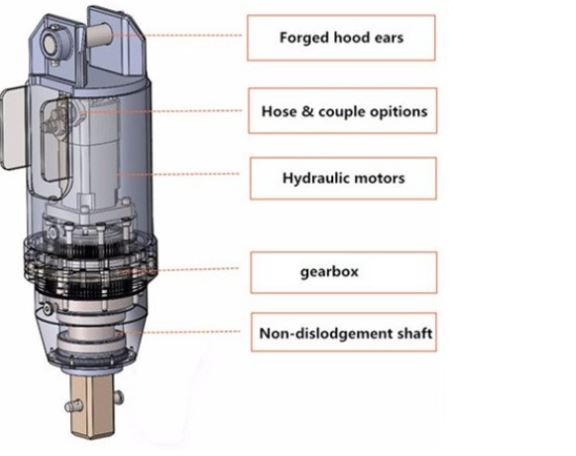

- Industrial gearboxes (cement, steel, mining industries)

- Marine propulsion systems (corrosion-resistant variants available)

- Wind turbine yaw drives (special low-temperature versions)

- Aerospace actuation systems (premium-grade lightweight options)

- Railway traction systems (vibration-optimized designs)

Quality Assurance

All Spiral Bevel Gears undergo comprehensive quality control:

| Test | Standard | Acceptance Criteria |

|---|---|---|

| Hardness | Rockwell C Scale | 58-62 HRC |

| Profile Accuracy | DIN 3962 | ≤ 0.005mm |

| Surface Roughness | ISO 1302 | Ra ≤ 1.6μm |

| Noise Test | ISO 8579-1 | ≤ 75 dB @ 1000rpm |

| Dynamic Balance | ISO 1940-1 | G2.5 grade |