Blog

09 2026-02

09 2026-02 How to choose the right driveline motor for my irrigation system?

Selecting the optimal driveline motor is crucial for an efficient and reliable irrigation system. This guide outlines key factors to consider for making the best choice.

06 2026-02

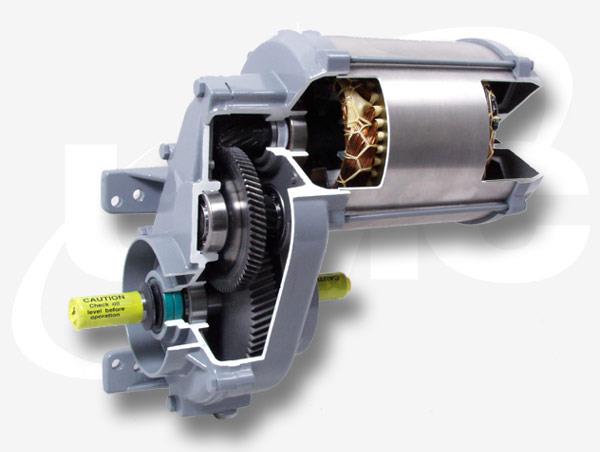

06 2026-02 What factors affect the lifespan of a driveline gearbox in irrigation systems?

This article explores the key factors influencing the longevity and reliability of driveline gearboxes in irrigation systems.

30 2026-01

30 2026-01 How to maintain and lubricate a greenhouse reducer?

A brief guide on the essential steps and best practices for maintaining and lubricating a greenhouse reducer to ensure optimal performance and longevity.

29 2026-01

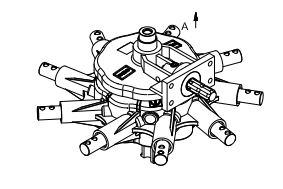

29 2026-01 What are the key components inside a side-delivery rake gearbox?

An introduction to the main parts and their functions within a side-delivery rake gearbox.

22 2026-01

22 2026-01 What is the cost range for a new or replacement PTO speed reducer?

A brief overview of the pricing factors and typical cost range for new or replacement PTO speed reducers.

21 2026-01

21 2026-01 What are slasher gearboxes and how do they work?

Slasher gearboxes are specialized transmission units designed for high-performance applications, enhancing power delivery and durability in demanding machinery.