plastic Gears

Plastic Gears: The Complete Guide to High-Performance Engineering Solutions

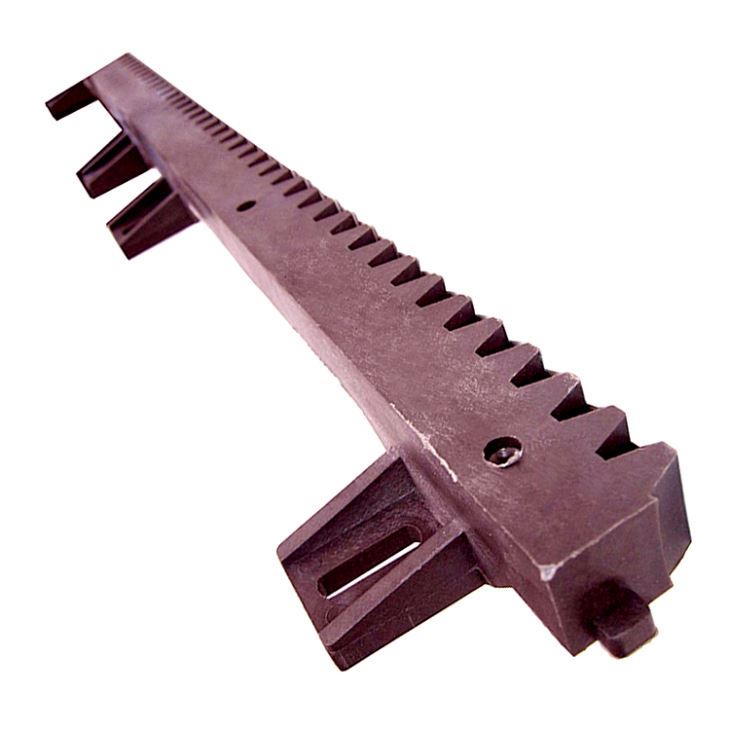

Plastic gears have become essential components in modern machinery due to their lightweight, corrosion resistance, and cost-effectiveness compared to metal gears. Our premium plastic gears offer exceptional durability and precision for various industrial applications.

Key Features of Our Plastic Gears

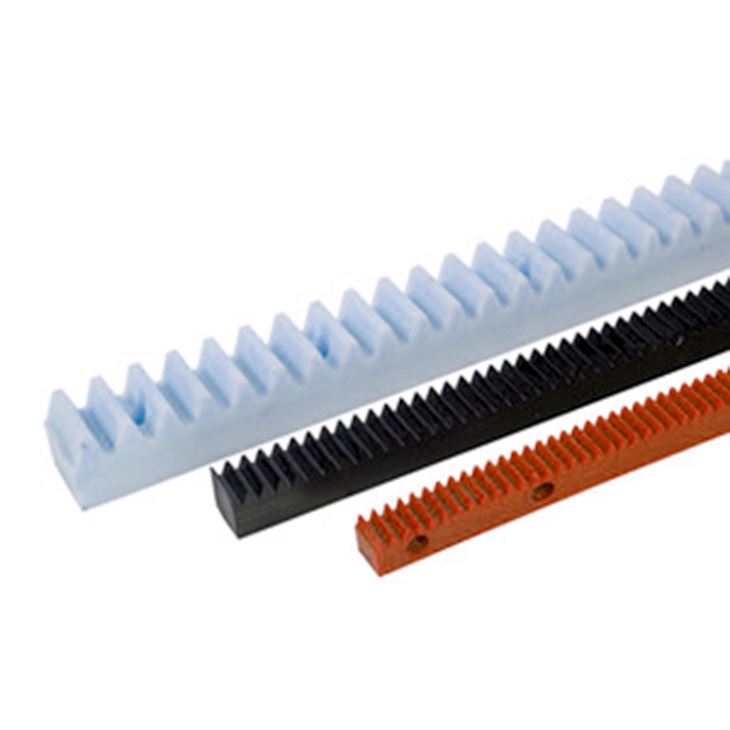

- High-strength polymer materials (POM, Nylon, PEEK)

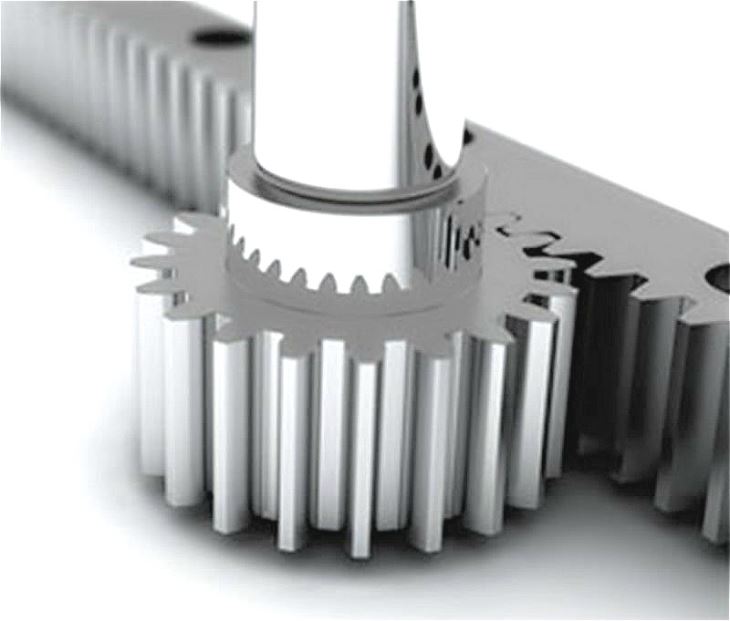

- Precision-molded teeth for smooth operation

- Wear-resistant surfaces with low friction coefficients

- Noise reduction capabilities

- Chemical and moisture resistance

- Customizable sizes and tooth profiles

Technical Specifications

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Material | POM, Nylon 6/6, PEEK | Available upon request |

| Module (mm) | 0.5-5.0 | Up to 8.0 |

| Pressure Angle | 20° (Standard), 14.5° | Custom angles available |

| Operating Temperature | -40°C to +120°C | Special grades up to +250°C |

| Tooth Finish | Molded as standard | Machined options available |

Plastic Gears Applications

Our plastic gears are used across multiple industries including:

- Automotive systems (window regulators, seat adjusters)

- Medical equipment (pump mechanisms, diagnostic devices)

- Consumer electronics (printers, scanners, appliances)

- Industrial machinery (conveyor systems, packaging equipment)

- Robotics and automation components

Plastic Gears Frequently Asked Questions

Q: What are the main advantages of plastic gears over metal gears?

A: Plastic gears offer several benefits including lighter weight (up to 80% reduction), inherent lubrication properties, corrosion resistance, noise reduction (up to 50% quieter operation), and cost-effectiveness for medium-duty applications. They also eliminate electrical conductivity concerns and don't require additional surface treatments.

Q: How do I choose the right plastic material for my gear application?

A: Material selection depends on multiple factors: POM (acetal) offers excellent dimensional stability and low friction for precision applications; Nylon provides good impact resistance and fatigue life; PEEK is suited for high-temperature environments. We recommend consulting our engineers who will consider your load requirements, operating environment, temperature range, and chemical exposure to suggest the optimal material.

Q: What maintenance do plastic gears require?

A: Plastic gears typically require less maintenance than metal gears. They don't need lubrication in many applications, though some high-performance polymers may benefit from occasional grease application. Regular inspection for wear patterns or deformation is recommended, with typical service life ranging from 500,000 to over 5 million cycles depending on load conditions and material selection.

Performance Comparison Table

| Material | Tensile Strength (MPa) | Max Continuous Temp (°C) | Moisture Absorption (%) | Ideal Applications |

|---|---|---|---|---|

| POM (Acetal) | 60-70 | 90-100 | 0.2-0.3 | Precision mechanisms, food processing |

| Nylon 6/6 | 80-90 | 80-120 | 1.2-1.5 | General industrial, automotive |

| PEEK | 90-100 | 250 | 0.1-0.2 | High-temperature, chemical exposure |

Custom Plastic Gears Solutions

We specialize in manufacturing custom plastic gears tailored to your specific requirements:

- Prototype development with rapid tooling options

- Small to large production runs (100 to 1M+ units)

- Complete gearbox design services

- Testing and validation services

- Reverse engineering of existing components

Our engineering team works closely with clients to develop optimal plastic gear solutions that meet exact performance specifications while maintaining cost-efficiency. Contact us today to discuss your project requirements and receive a customized quotation for your plastic gears needs.