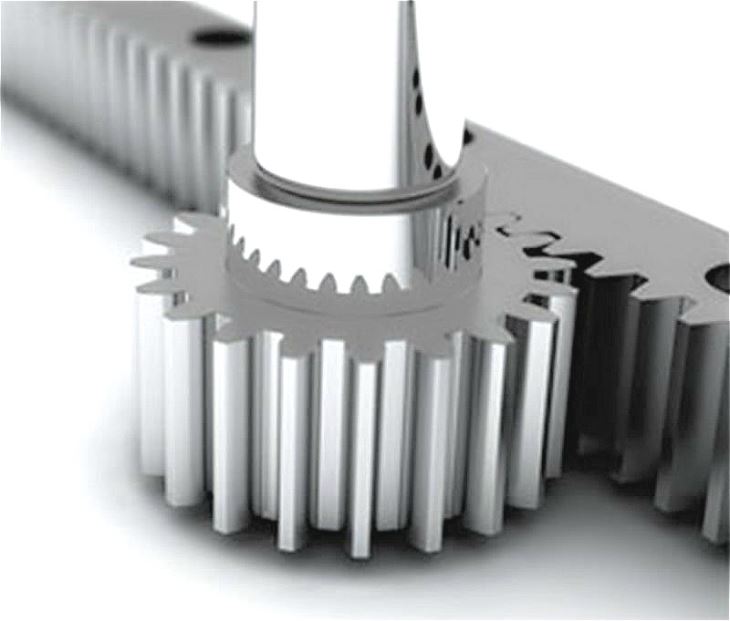

stainless Steel Gears

Premium Stainless Steel Gears for Industrial Applications

Our high-performance stainless steel gears are engineered to deliver exceptional durability and precision in demanding industrial environments. Manufactured with aircraft-grade 304 and 316 stainless steel, these gears offer superior corrosion resistance and mechanical strength compared to standard carbon steel alternatives.

Key Product Specifications

- Material: 304/316 Stainless Steel (ASTM A276 compliant)

- Surface Hardness: HRC 40-45 (heat treated)

- Tooth Profile: Involute (20° pressure angle)

- Precision Grade: AGMA Q9-Q12

- Operating Temperature: -40°C to 400°C (-40°F to 752°F)

- Surface Finish: 0.8μm Ra (mirror polishing available)

Stainless Steel Gears Technical Comparison

| Parameter | 304 Stainless Steel | 316 Stainless Steel | Carbon Steel |

|---|---|---|---|

| Tensile Strength (MPa) | 515 | 515 | 460 |

| Yield Strength (MPa) | 205 | 205 | 250 |

| Corrosion Resistance | Excellent | Superior (Mo content) | Poor |

| Weight (kg/dm³) | 7.93 | 7.98 | 7.85 |

Stainless Steel Gears - Frequently Asked Questions

Q: What makes stainless steel gears better than regular steel gears?

A: Stainless steel gears offer superior corrosion resistance, making them ideal for wet or chemically aggressive environments. They maintain dimensional stability better than carbon steel when exposed to temperature variations and don't require protective coatings that can wear off over time. While slightly more expensive initially, stainless steel gears typically demonstrate lower total cost of ownership due to extended service life.

Q: How do I choose between 304 and 316 stainless steel gears?

A: 304 stainless steel gears are suitable for most general applications with moderate chemical exposure. Choose 316 stainless steel gears when operating in marine environments or when exposed to chlorides, acids, or other aggressive chemicals. The molybdenum content in 316 provides enhanced pitting resistance. For food processing or medical applications, we recommend 316L (low carbon variant) for superior cleanability and corrosion resistance.

Q: What maintenance do stainless steel gears require?

A: Stainless steel gears require significantly less maintenance than carbon steel gears. Regular inspections for wear and proper lubrication are recommended. Use food-grade lubricants when appropriate. Avoid lubricants with chlorinated additives as they can cause stress corrosion cracking. Periodic cleaning with mild detergents (no chloride cleaners) helps maintain corrosion resistance. Proper alignment during installation prevents premature wear.

Available Stainless Steel Gears Configurations

| Type | Module Range | Diameter Range (mm) | Tooth Count | Standard |

|---|---|---|---|---|

| Spur Gears | 1-8 | 20-500 | 12-120 | DIN 867 / AGMA 2002 |

| Helical Gears | 1-6 | 25-400 | 15-90 | DIN 3960 / AGMA 2102 |

| Bevel Gears | 1-5 | 30-300 | 10-60 | DIN 3971 / AGMA 2005 |

Applications for Stainless Steel Gears

- Food processing and packaging equipment

- Marine propulsion systems

- Pharmaceutical manufacturing

- Chemical processing plants

- Wastewater treatment facilities

- High-temperature industrial ovens

- Cryogenic equipment

- Medical device manufacturing

Custom Stainless Steel Gears Solutions

We specialize in manufacturing custom stainless steel gears tailored to specific operational requirements. Our engineering team can assist with:

- Non-standard module sizes

- Special tooth profiles

- Modified pressure angles

- Integrated shaft designs

- Special surface treatments

- Precision grinding services

Benefits of Our Stainless Steel Gears

- Extended Service Life: 3-5 times longer than carbon steel equivalents

- Hygienic Design: Smooth surfaces prevent bacterial growth

- Low Maintenance: No rust prevention treatments required

- Temperature Stable: Minimal thermal expansion

- Chemical Resistance: Withstands acids, alkalis, and saltwater