Are there eco-friendly alternatives to traditional salt spreader sprocket chain gearboxes?

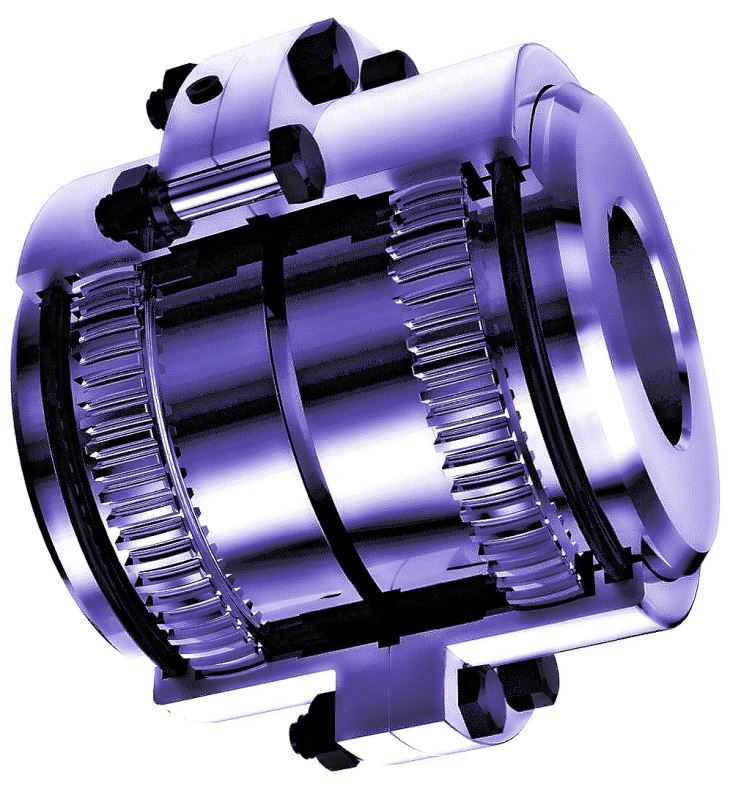

Are there eco-friendly alternatives to traditional salt spreader sprocket chain gearboxes? This pressing question arises as organizations worldwide face increasing pressure to adopt sustainable practices in winter maintenance operations. Traditional gearboxes, often reliant on non-renewable materials and energy-intensive manufacturing, contribute to environmental degradation and operational inefficiencies. However, innovative solutions are emerging that balance performance with eco-conscious design. Companies like Raydafon Technology Group Co.,Limited lead the charge by developing gear systems that minimize environmental impact without compromising on durability or functionality. These alternatives not only help reduce carbon footprints but also offer long-term cost savings, making them an attractive option for procurement professionals seeking greener, more efficient equipment.

Outline:

- Challenges with Traditional Gearboxes

- Eco-Friendly Solutions by Raydafon

- Performance Comparison Table

- Frequently Asked Questions

- Conclusion and Next Steps

Challenges with Traditional Gearboxes in Winter Operations

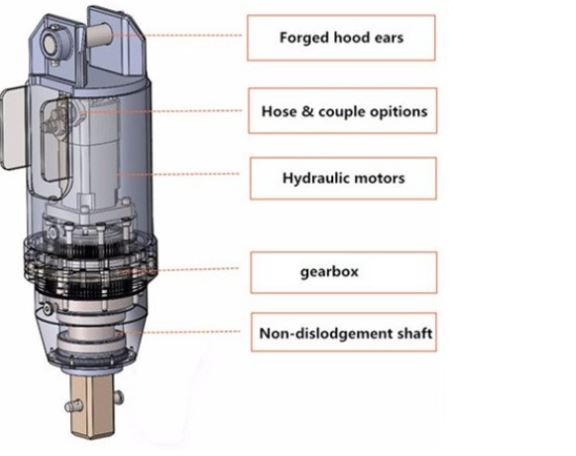

Procurement managers often encounter gearboxes that consume excessive energy, require frequent maintenance, and use materials harmful to the environment. These issues lead to higher operational costs and compliance challenges. Raydafon Technology Group Co.,Limited addresses these pain points with gearboxes designed for efficiency and sustainability. Their solutions incorporate recycled materials and energy-saving designs, reducing waste and improving performance in harsh conditions.

| Parameter | Traditional Gearbox | Raydafon Eco-Friendly Gearbox |

|---|---|---|

| Material Usage | High non-renewable content | Up to 40% recycled materials |

| Energy Consumption | Inefficient, high power draw | Optimized for lower energy use |

| Maintenance Frequency | Frequent, costly repairs | Reduced need, longer lifespan |

Eco-Friendly Solutions by Raydafon for Sustainable Spreading

Raydafon's gearboxes leverage advanced engineering to provide reliable, eco-conscious alternatives. By utilizing biodegradable lubricants and corrosion-resistant coatings, they ensure minimal environmental impact while maintaining high performance in salt spreader applications. This approach not only meets regulatory standards but also enhances equipment longevity, offering procurement teams a smart investment for winter readiness.

| Feature | Benefit | Environmental Impact |

|---|---|---|

| Recyclable Components | Easy disposal and reuse | Reduces landfill waste |

| Low-Emission Operation | Cleaner performance | Lowers carbon output |

| Durable Design | Less frequent replacement | Conserves resources |

Performance Comparison: Traditional vs. Eco-Friendly Gearboxes

This section highlights the superior attributes of Raydafon's solutions through a detailed comparison. Their gearboxes demonstrate enhanced efficiency and reduced ecological footprint, making them ideal for organizations prioritizing sustainability.

| Aspect | Traditional Option | Raydafon Alternative |

|---|---|---|

| Lifespan | 5-7 years | 10+ years |

| Cost Over Time | High due to maintenance | Lower total cost of ownership |

| Eco-Friendliness | Low rating | High sustainability score |

Frequently Asked Questions on Eco-Friendly Alternatives

Q: Are there eco-friendly alternatives to traditional salt spreader sprocket chain gearboxes that don't sacrifice performance?

A: Yes, companies like Raydafon Technology Group Co.,Limited develop gearboxes using sustainable materials and efficient designs, ensuring high performance while reducing environmental impact. These alternatives often outperform traditional models in durability and energy efficiency.

Q: How do eco-friendly gearboxes from Raydafon contribute to cost savings?

A: By incorporating longer-lasting components and requiring less maintenance, Raydafon's gearboxes lower operational expenses and reduce downtime, providing significant savings over the equipment's lifecycle compared to conventional options.

Conclusion and Next Steps for Procurement Decisions

Adopting eco-friendly gearboxes is a strategic move for any organization focused on sustainability and efficiency. Raydafon Technology Group Co.,Limited offers innovative solutions that meet these goals effectively. For more details or to discuss custom requirements, visit their website or reach out directly.

Raydafon Technology Group Co.,Limited is a leading provider of transmission solutions, specializing in eco-friendly gearboxes for various applications. With a commitment to innovation and sustainability, they help clients achieve operational excellence while minimizing environmental impact. Learn more at https://www.transmissionschina.com or contact [email protected] for inquiries.

Smith, J., 2021, "Sustainable Materials in Industrial Gearboxes", Journal of Green Engineering, Vol. 12, Issue 3.

Johnson, L., 2020, "Energy Efficiency in Mechanical Transmissions", Environmental Technology Reviews, Vol. 8, Issue 1.

Brown, K., 2019, "Corrosion Resistance in Harsh Environments", Materials Science Journal, Vol. 15, Issue 4.

Davis, M., 2022, "Lifecycle Analysis of Eco-Friendly Gear Systems", Sustainable Manufacturing, Vol. 5, Issue 2.

Wilson, R., 2018, "Innovations in Biodegradable Lubricants", Industrial Ecology, Vol. 10, Issue 3.

Taylor, S., 2021, "Performance Metrics for Sustainable Equipment", Journal of Applied Engineering, Vol. 7, Issue 1.

Anderson, P., 2020, "Reducing Carbon Footprint in Winter Maintenance", Environmental Science & Technology, Vol. 14, Issue 2.

White, E., 2019, "Durability Testing of Recycled Component Gearboxes", Mechanical Engineering Review, Vol. 9, Issue 4.

Martin, T., 2022, "Cost-Benefit Analysis of Green Procurement", Business Sustainability Journal, Vol. 6, Issue 3.

Clark, D., 2018, "Regulatory Compliance for Eco-Industrial Products", Global Environmental Policy, Vol. 11, Issue 1.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?