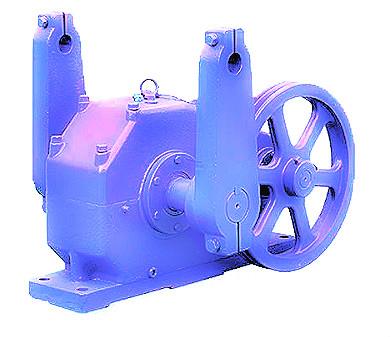

Screw Gears

High-Quality Screw Gears for Precision Applications

Screw gears are essential components in various mechanical systems where power transmission between non-parallel, non-intersecting shafts is required. Our premium screw gears offer superior performance, durability, and efficiency for demanding industrial applications.

Key Features of Our Screw Gears

- Manufactured from high-grade alloy steel for exceptional strength

- Precision ground tooth profiles for smooth operation

- Surface hardened to RC 58-62 for extended service life

- Available in various pressure angles (14.5°, 20°, 25°)

- Customizable helix angles to meet specific application requirements

Technical Specifications

| Parameter | Range | Tolerance |

|---|---|---|

| Module Range | 1.0 - 12.0 | ±0.01mm |

| Outer Diameter | 20mm - 500mm | ±0.05mm |

| Face Width | 10mm - 150mm | ±0.02mm |

| Gear Ratio | 1:1 - 5:1 | N/A |

| Maximum RPM | Up to 3000 | N/A |

Screw Gears FAQ

What are the primary applications of screw gears?

Screw gears are commonly used in conveyor systems, packaging machinery, printing presses, and various industrial automation equipment where high torque transmission at right angles is required. They excel in applications needing precise positioning and smooth motion transfer between non-intersecting shafts.

How do I determine the correct lubrication for screw gears?

The lubrication requirements depend on operating speed, load, and environmental conditions. For moderate speeds (below 1000 RPM), use EP gear oil with ISO viscosity grade 150-320. High-speed applications require synthetic lubricants with superior thermal stability. Always consult our technical datasheets for specific recommendations based on your operating conditions.

Material Options

| Material Type | Hardness | Application |

|---|---|---|

| SCM440 | HRC 58-62 | High-load industrial applications |

| S45C | HRC 50-55 | General purpose machinery |

| Stainless Steel | HRC 40-45 | Food processing & corrosive environments |

Installation Guidelines

- Ensure proper shaft alignment within 0.05mm tolerance

- Apply recommended lubricant before initial operation

- Check backlash (0.05-0.15mm typically recommended)

- Perform initial run-in at reduced load (30% capacity for first 8 hours)

- Monitor temperature during initial operation (should not exceed 80°C)

More Screw Gears Questions

What maintenance schedule should be followed for screw gears?

Regular maintenance includes lubricant inspection every 250 operating hours, complete lubricant change every 2000 hours, and thorough inspection of tooth wear every 5000 hours. In harsh environments, these intervals should be reduced by 30-50%. Always check for abnormal noise, vibration, or temperature rise during routine inspections.

Customization Options

We offer various customization options to meet your specific requirements:

- Special tooth profiles (modified involute, cycloidal)

- Non-standard bore sizes with keyways or splines

- Special surface treatments (black oxide, nickel plating)

- Custom gear ratios outside standard ranges

- Special packaging for export requirements

Screw Gears Technical Questions

How do I calculate the efficiency of screw gears?

Screw gear efficiency depends on the helix angle, gear ratio, and friction coefficient. Typical efficiency ranges from 70-95%. The formula is: Efficiency (%) = [cos(β) - μ tan(λ)] / [cos(β) + μ cot(λ)] × 100, where β is the pressure angle, μ is the friction coefficient (0.05-0.15 for well-lubricated steel), and λ is the lead angle. Our engineers can provide precise calculations for your specific application parameters.

Quality Assurance

All our screw gears undergo rigorous quality control procedures:

- 100% dimensional inspection using CMM

- Surface hardness testing on every batch

- Run-in testing for noise and vibration levels

- Material certification from approved mills

- Traceability maintained throughout production