Differential Gears

Premium Differential Gears for Superior Performance

Differential gears play a critical role in vehicle performance by allowing wheels to rotate at different speeds while maintaining power distribution. Our high-quality differential gears are engineered for durability, precision, and maximum efficiency.

Key Product Specifications

- Material: Forged alloy steel with advanced heat treatment

- Surface Hardness: 58-62 HRC for exceptional wear resistance

- Gear Ratio Options: 3.23, 3.42, 3.73, 4.10, 4.56

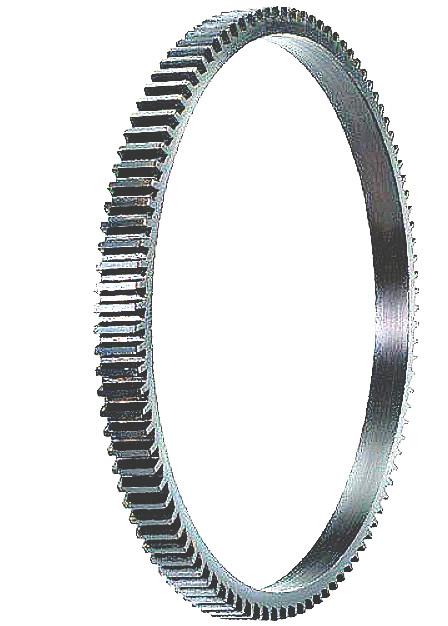

- Teeth Count: 28, 30, 32, 35, 38 (standard configurations)

- Precision Rating: AGMA 12 or better (depends on application)

- Operating Temperature: -40°F to 300°F (-40°C to 149°C)

| Model | Weight (lbs) | Max Torque Capacity (lb-ft) | Compatibility |

|---|---|---|---|

| DG-200 | 18.5 | 450 | Compact cars, FWD |

| DG-300 | 25.7 | 650 | SUV, light trucks |

| DG-400 | 32.8 | 900 | Heavy-duty trucks |

| DG-500 | 45.2 | 1200 | Performance/Racing |

Performance Advantages

- 30% stronger than OEM differential gears in stress tests

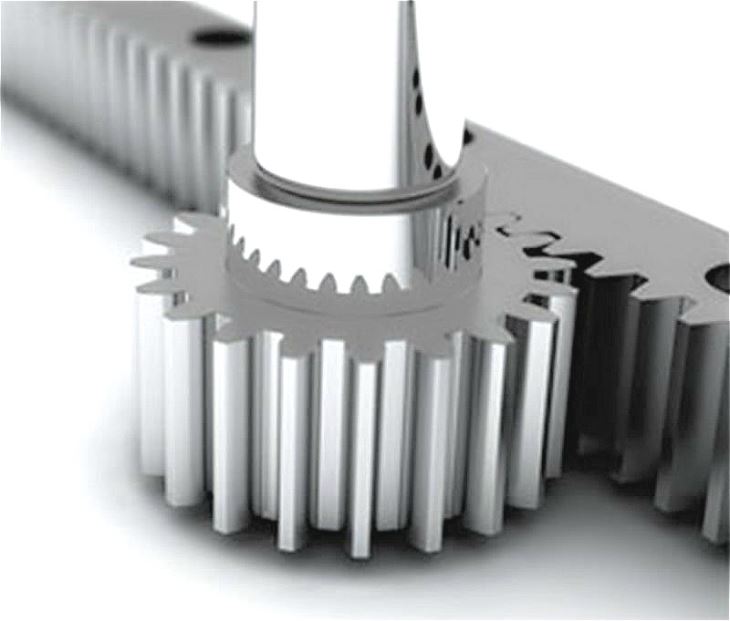

- Precision CNC machining for perfect gear meshing

- Special coating reduces friction and heat buildup

- Tested for 500+ hours under extreme conditions

Differential Gears FAQ

Q: How often should differential gears be inspected?

A: For normal street use, inspect differential gears every 30,000 miles or during regular maintenance intervals. Off-road vehicles or performance applications should be checked every 15,000 miles or after extreme use. Look for unusual wear patterns, chipped teeth, or discoloration which indicates overheating.

Q: What's the difference between hypoid and spiral bevel differential gears?

A: Hypoid gears have offset axes allowing lower drivetrain height and quieter operation, while spiral bevel gears have intersecting axes with slightly higher efficiency. Hypoid designs are common in rear-wheel drive vehicles, offering greater torque capacity. Spiral bevel gears are typically found in front-wheel drive applications where space is limited.

Q: Can I install these differential gears myself?

A: Differential gear installation requires specialized tools and precise setup (including proper backlash and pinion depth measurements). We recommend professional installation unless you have experience with differential rebuilds. Improper installation can lead to premature failure, noise, and safety hazards.

Technical Comparison

| Feature | Standard OEM | Our Differential Gears |

|---|---|---|

| Material Quality | 8620 steel | 4340 chromoly steel |

| Heat Treatment | Standard carburizing | Precision vacuum heat treatment |

| Surface Finish | 6-8 Ra µin | 3-4 Ra µin (mirror finish) |

| Warranty | 12 months | 36 months |

Maintenance Tips for Differential Gears

- Use manufacturer-recommended gear oil (typically 75W-90 or 80W-140)

- Change fluid every 30,000-50,000 miles under normal conditions

- For severe service (towing, racing), change every 15,000 miles

- Check for leaks at seals and cover plate

- Listen for unusual noises (whining, clunking) during operation

Q: What causes differential gears to whine?

A: Differential gear whine typically results from improper gear mesh pattern, incorrect backlash, worn bearings, or inadequate lubrication. Sometimes it indicates improper break-in procedures or contaminated gear oil. Our differential gears include detailed installation specifications to minimize noise issues.

Q: Are limited-slip differential gears different from standard ones?

A: The core gear teeth are similar, but limited-slip differentials include additional clutch packs or mechanisms to control wheel slip. Both types use the same fundamental gear design principles, though limited-slip units often require special friction modifiers in the gear oil.

Q: How do I choose the right gear ratio for my differential gears?

A: The ideal ratio depends on tire size, engine power band, and intended use. Lower numerical ratios (3.23) improve highway fuel economy while higher ratios (4.10+) provide better acceleration. Our technical team can recommend the optimal ratio based on your vehicle specifications and performance goals.

Installation Requirements

| Tool | Purpose | Criticality |

|---|---|---|

| Dial Indicator | Measure backlash | Essential |

| In-lb Torque Wrench | Pinion preload | Essential |

| Bearing Puller | Remove/install bearings | Recommended |

| Pattern Compound | Check gear contact | Essential |

Q: Do differential gears need a break-in period?

A: Yes, new differential gears require a 500-mile break-in period. Avoid towing, hard acceleration, and sustained high speeds during this time. The break-in allows gear surfaces to properly mate and distributes wear patterns evenly. Change the gear oil after break-in to remove metal particles.

Q: What's the lifespan of quality differential gears?

A: Properly maintained differential gears can last 150,000+ miles in normal street use. Severe service applications may reduce lifespan to 50,000-75,000 miles. Our differential gears undergo accelerated life testing equivalent to 200,000 miles of normal operation.

Q: Can I mix different brands of differential gears?

A: We strongly recommend against mixing gear sets from different manufacturers. Even slight variations in tooth profile or heat treatment can cause premature wear. Always use matched gear sets (ring & pinion) from the same production batch for optimal performance.