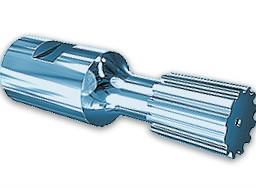

Spline Shaft

High-Quality Spline Shafts for Industrial Applications

Spline shafts are essential components in power transmission systems, providing precise torque transfer between connected parts. Our spline shafts are manufactured to the highest industry standards using premium materials and advanced machining techniques. With over two decades of experience in mechanical engineering solutions, we deliver spline shafts that meet the most demanding industrial requirements.

Key Features of Our Spline Shafts

- Precision machined with tight tolerances (±0.0005")

- Available in various tooth profiles (involute, straight-sided, serrated)

- Manufactured from high-strength alloy steel (4140, 4340) or stainless steel

- Multiple surface treatment options (black oxide, zinc plating, nitriding)

- Custom lengths up to 6 meters available

- Diameters ranging from 10mm to 300mm

Spline Shaft Technical Specifications

| Parameter | Specification | Measurement |

|---|---|---|

| Material | 4140/4340 Alloy Steel | - |

| Tensile Strength | 850-1200 MPa | MPa |

| Hardness | 28-32 HRC | Rockwell C |

| Surface Finish | 0.8-1.6 μm Ra | Microns |

| Straightness Tolerance | 0.05 mm/m | mm per meter |

| Tooth Profile Accuracy | DIN Class 5-7 | - |

Spline Shaft FAQ - Part 1

Q: What are the main types of spline shaft profiles available?

A: There are three primary spline shaft profiles: involute (most common for high torque applications), straight-sided (simpler to manufacture), and serrated (used when axial movement is required). Involute splines provide the best load distribution and are self-centering, making them ideal for precision applications. The choice depends on your specific torque requirements, manufacturing capabilities, and operational conditions.

Manufacturing Process

Our spline shafts undergo a rigorous manufacturing process to ensure dimensional accuracy and mechanical properties:

- Material selection and verification

- Precision CNC turning

- Spline milling or hobbing

- Heat treatment (quenching and tempering)

- Precision grinding

- Surface finishing

- 100% quality inspection

Applications

- Automotive transmissions and drivetrains

- Industrial gearboxes and reducers

- Aerospace actuation systems

- Marine propulsion systems

- Heavy construction equipment

- Agricultural machinery

- Robotics and automation systems

Spline Shaft FAQ - Part 2

Q: How do I determine the correct spline shaft size for my application?

A: Determining spline shaft size involves calculating torque requirements, considering space constraints, and evaluating service conditions. Key factors include: torque capacity (based on material and heat treatment), number of teeth (affects load distribution), pressure angle (typically 30° or 37.5°), and fit class (determines clearance between mating parts). Our engineering team can assist with proper spline selection based on your specific application parameters.

Quality Assurance

All our spline shafts undergo comprehensive testing to ensure they meet international standards:

- Dimensional verification with CMM

- Hardness testing (Rockwell and Brinell)

- Surface roughness measurement

- Magnetic particle inspection for surface defects

- Ultrasonic testing for internal flaws

- Functional testing with mating components

Customization Options

We offer complete customization for spline shafts to meet your exact requirements:

- Special materials (titanium, superalloys)

- Unique tooth profiles (modified involute, double helix)

- Integrated features (flanges, keyways, threads)

- Special coatings (PTFE, hard chrome)

- Precision balancing for high-speed applications

- Custom packaging and labeling

Spline Shaft FAQ - Part 3

Q: What maintenance is required for spline shafts?

A: Spline shafts generally require minimal maintenance, but proper care extends service life. Regular lubrication with appropriate grease prevents wear and corrosion in sliding applications. Inspect periodically for: tooth wear patterns (indicating misalignment), surface pitting (inadequate lubrication), and corrosion (especially in harsh environments). For fixed connections, check torque values of retaining fasteners during scheduled maintenance. Always use proper handling procedures to avoid damaging the spline teeth during installation or removal.

Why Choose Our Spline Shafts?

- 20+ years of precision manufacturing experience

- ISO 9001:2015 certified production

- Advanced CNC machining capabilities

- Custom engineering support

- Competitive pricing with short lead times

- Global shipping and logistics network

- Comprehensive after-sales support

Our spline shafts deliver reliable performance in the most demanding applications. Contact our technical team today to discuss your specific requirements and receive expert recommendations for your power transmission needs.