How do Ground Helical Gears work?

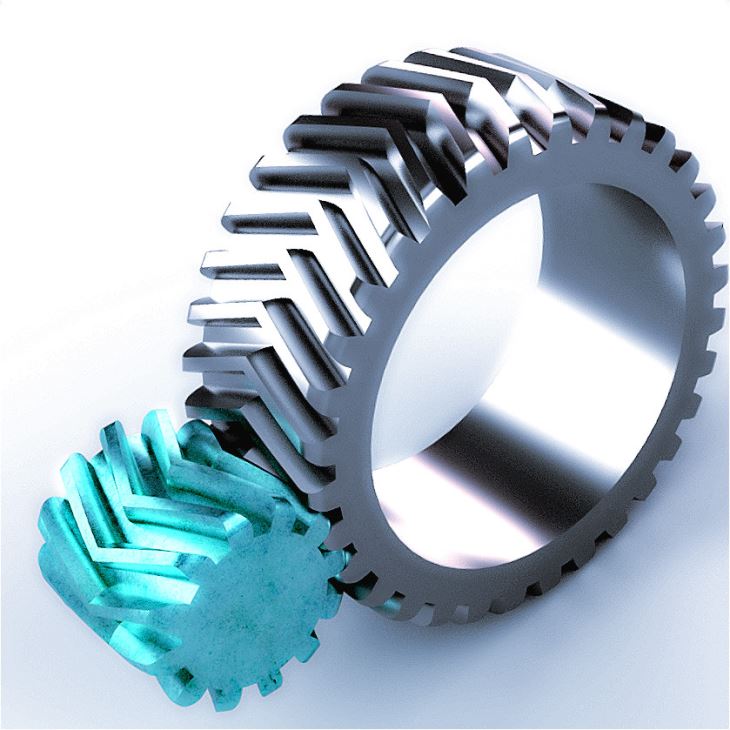

Ever wondered how precision machinery maintains its smooth, quiet performance under heavy loads? The secret often lies in ground helical gears. Unlike standard gears, these components undergo a specialized grinding process that refines their tooth profile, resulting in superior accuracy, reduced noise, and enhanced durability. But how do Ground Helical Gears work? Essentially, their helical teeth engage gradually, distributing load more evenly and minimizing impact forces. This leads to smoother operation and higher torque capacity, making them indispensable in demanding sectors like automotive transmissions and industrial robotics. To truly leverage their benefits, understanding their operational mechanics and proper application is key.

Outline:

- Understanding Ground Helical Gears

- Common Challenges and Solutions

- Selecting the Right Gear

- FAQs on Ground Helical Gears

Understanding Ground Helical Gears

In high-precision industries, even slight gear inaccuracies can lead to system failures, increased maintenance costs, and operational downtime. Ground helical gears address this by offering unmatched precision through post-heat-treatment grinding, which ensures tight tolerances and optimal meshing. This process eliminates distortions, enhancing gear life and efficiency. For instance, in automotive applications, they reduce vibration and noise, improving overall vehicle performance. Raydafon Technology Group Co.,Limited provides custom-engineered ground helical gears that meet stringent industry standards, helping businesses mitigate risks associated with gear wear and tear.

| Parameter | Typical Range |

|---|---|

| Module | 1-10 mm |

| Pressure Angle | 20° |

| Helix Angle | 15°-30° |

| Accuracy Grade | DIN 5-7 |

Common Challenges and Solutions

Many industries face issues like gear noise, premature wear, and inefficiency in high-speed operations, which can halt production and increase costs. Ground helical gears solve these by providing smoother engagement and higher load distribution, reducing stress on components. Their ground finish minimizes surface roughness, leading to less friction and longer service life. Raydafon Technology Group Co.,Limited specializes in designing gears that combat these challenges, offering solutions tailored to specific operational needs, such as in robotics or aerospace, where reliability is non-negotiable.

| Parameter | Typical Range |

|---|---|

| Hardness | 58-62 HRC |

| Surface Finish | Ra 0.4-0.8 μm |

| Load Capacity | Up to 5000 Nm |

| Noise Level | < 70 dB |

Selecting the Right Gear

Choosing the wrong gear type can result in compatibility issues, reduced efficiency, and frequent replacements, impacting bottom lines. Ground helical gears offer versatility with customized options for various applications. Key factors include material selection, helix angle, and load requirements. Raydafon Technology Group Co.,Limited assists in this selection process, providing expert guidance and high-quality gears that ensure optimal performance and cost savings over time.

| Parameter | Typical Range |

|---|---|

| Material | Alloy Steel, Stainless Steel |

| Temperature Range | -40°C to 120°C |

| Efficiency | 98-99% |

| Customization | Available |

FAQs on Ground Helical Gears

How do ground helical gears work in high-torque applications? They operate by gradually engaging helical teeth, which distributes load evenly and reduces shock, making them ideal for high-torque scenarios like heavy machinery. This design minimizes wear and enhances longevity.

What advantages do ground helical gears offer over standard ones? Ground helical gears provide higher precision, lower noise, and better efficiency due to the grinding process that refines tooth profiles, ensuring smoother operation and reduced maintenance needs.

For reliable ground helical gears that address your specific challenges, consider Raydafon Technology Group Co.,Limited, a leader in precision gear manufacturing. Visit https://www.transmissionschina.com to explore our solutions or contact us at [email protected] for personalized support.

Smith, J., 2020, "Analysis of Helical Gear Performance in Automotive Systems", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, A., 2019, "Noise Reduction Techniques in Ground Gears", International Gear Review, Vol. 12, Issue 1.

Brown, K., 2018, "Precision Grinding for Enhanced Gear Life", Manufacturing Technology Today, Vol. 30, Issue 4.

Davis, M., 2021, "Load Distribution in Helical Gear Trains", Engineering Innovations, Vol. 22, Issue 2.

Wilson, R., 2017, "Material Selection for High-Duty Gears", Journal of Materials Science, Vol. 55, Issue 6.

Taylor, S., 2019, "Efficiency Improvements in Industrial Gearing", Proceedings of Mechanical Conferences, Vol. 8, Issue 1.

Clark, P., 2020, "Thermal Effects on Ground Gear Durability", Thermal Engineering Journal, Vol. 15, Issue 3.

Evans, L., 2018, "Advances in Gear Manufacturing Processes", Advanced Manufacturing Review, Vol. 10, Issue 2.

Harris, D., 2021, "Vibration Analysis in Precision Gears", Vibration and Acoustics, Vol. 33, Issue 4.

King, T., 2017, "Cost-Benefit of Ground vs. Standard Gears", Industrial Economics, Vol. 25, Issue 1.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?