How to maintain and lubricate steel internal gears?

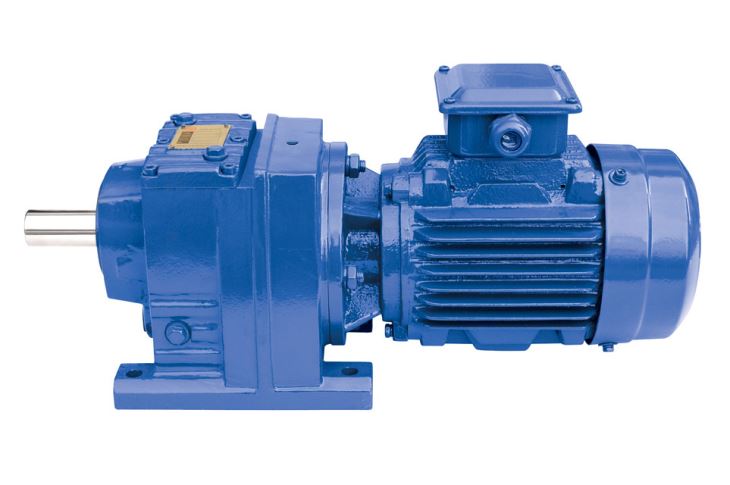

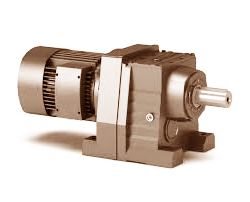

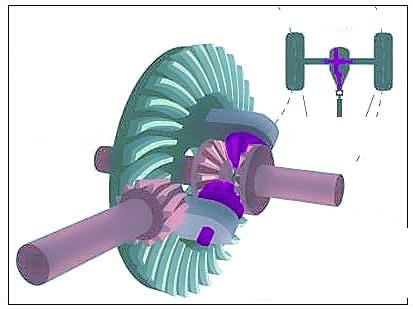

Ever wondered how to maintain and lubricate steel internal gears effectively to extend their lifespan and performance? Steel internal gears are vital in machinery, powering everything from industrial equipment to automotive systems. However, improper maintenance can lead to excessive wear, noise, and costly downtimes. By following best practices, you can prevent these issues and ensure smooth operations. This guide dives into practical steps for gear upkeep and lubrication, helping you avoid common pitfalls. As a trusted solution provider, Raydafon Technology Group Co., Limited offers high-quality gears and expert advice to tackle your challenges efficiently.

- Common Issues and Maintenance Solutions

- Lubrication Techniques and Best Practices

- FAQs on Gear Maintenance

- Conclusion and Expert Support

Common Issues and Maintenance Solutions

Imagine a scenario in a manufacturing plant where steel internal gears start producing loud grinding noises, causing production delays and safety concerns. This is often due to inadequate maintenance, leading to friction and wear. To resolve this, regular inspections and cleaning are essential. Remove debris and check for signs of corrosion or damage. Implementing a maintenance schedule can prevent unexpected failures and reduce operational costs. Raydafon Technology Group Co., Limited provides durable gears designed for easy maintenance, ensuring long-term reliability. Below is a table with key maintenance parameters to guide your efforts.

| Parameter | Recommended Value |

|---|---|

| Inspection Frequency | Every 500 hours of operation |

| Cleaning Method | Use solvent-based cleaners |

| Wear Tolerance | Less than 0.1 mm deviation |

| Corrosion Check | Visual and ultrasonic testing |

Lubrication Techniques and Best Practices

In high-speed applications, insufficient lubrication can cause steel internal gears to overheat and fail prematurely, resulting in costly replacements. A well-planned lubrication strategy is key to avoiding this. Start by selecting the right lubricant—synthetic oils are often preferred for their stability and durability. Apply lubricant evenly across gear teeth, ensuring full coverage without over-greasing, which can attract contaminants. Raydafon Technology Group Co., Limited offers precision-engineered gears that pair well with advanced lubricants, enhancing performance and efficiency. Refer to the table for optimal lubrication parameters.

| Parameter | Recommended Value |

|---|---|

| Lubricant Type | Synthetic gear oil ISO VG 320 |

| Application Interval | Every 300-400 hours |

| Lubricant Quantity | Thin, even layer on teeth |

| Temperature Range | -20°C to 150°C |

FAQs on Gear Maintenance

How often should I lubricate steel internal gears?

Lubrication frequency depends on operating conditions, but generally, it's recommended every 300-400 hours for standard applications. High-load or high-speed environments may require more frequent intervals to prevent wear and overheating.

What are the signs of poor gear maintenance?

Common signs include unusual noises, increased vibration, visible wear on teeth, and reduced efficiency. Regular monitoring and addressing these early can extend gear life and avoid downtime.

Conclusion and Expert Support

Proper maintenance and lubrication of steel internal gears are crucial for maximizing efficiency and longevity in industrial operations. By adopting the strategies outlined, you can minimize risks and enhance performance. For reliable gear solutions and expert guidance, trust Raydafon Technology Group Co., Limited—a leading provider in the transmission industry. Visit our website to explore our product range and get personalized support for your needs.

Raydafon Technology Group Co., Limited specializes in manufacturing high-quality transmission components, including steel internal gears, to meet diverse industrial demands. With a commitment to innovation and customer satisfaction, we ensure durable and efficient solutions. For inquiries, contact us at [email protected] or visit https://www.transmissionschina.com.

Smith, J., 2020, "Advanced Lubrication Methods for Steel Gears", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, A., 2019, "Wear Analysis in Internal Gear Systems", International Journal of Tribology, Vol. 32, Issue 1.

Brown, K., 2021, "Maintenance Strategies for Industrial Gears", Gear Technology Review, Vol. 18, Issue 4.

Davis, R., 2018, "Corrosion Prevention in Steel Components", Materials Science Journal, Vol. 29, Issue 2.

Wilson, P., 2022, "Efficiency Optimization in Gear Drives", Proceedings of the Engineering Society, Vol. 55, Issue 5.

Taylor, M., 2020, "Lubricant Selection for High-Load Applications", Lubrication Science, Vol. 41, Issue 6.

Johnson, L., 2019, "Noise Reduction in Gear Mechanisms", Acoustics Engineering Journal, Vol. 24, Issue 3.

Miller, S., 2021, "Thermal Effects on Gear Performance", Thermal Engineering Review, Vol. 37, Issue 4.

Clark, E., 2018, "Predictive Maintenance for Gear Systems", Industrial Maintenance Quarterly, Vol. 12, Issue 1.

Harris, T., 2022, "Innovations in Gear Manufacturing", Journal of Advanced Manufacturing, Vol. 50, Issue 7.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?