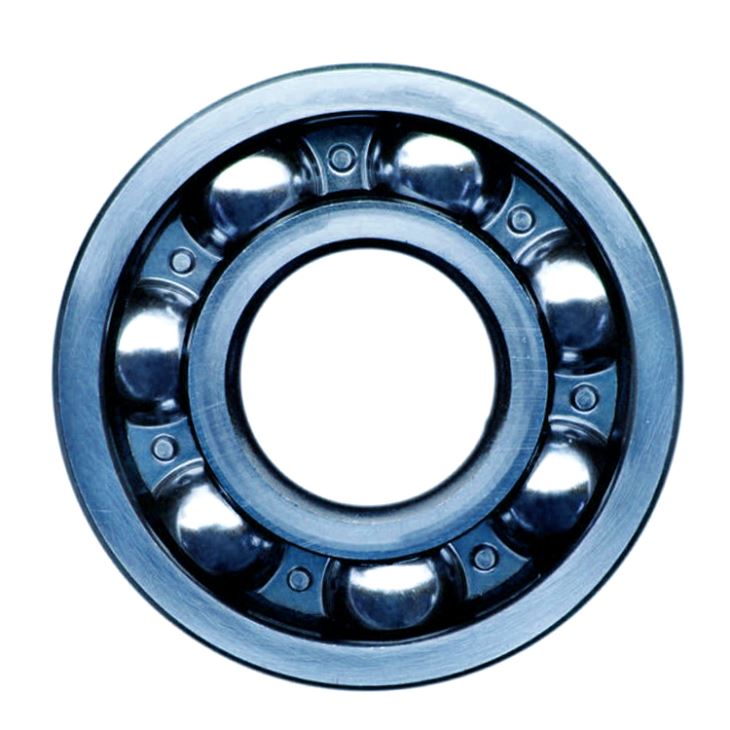

Bearing

Premium Bearings Engineered for Performance & Longevity

When sourcing industrial bearings, reliability and precision are non-negotiable. Raydafon, a leading China manufacturer, delivers high-performance bearings with strict quality control, competitive factory pricing, and fast turnaround for global buyers.

Why Choose Raydafon Bearings?

✅ ISO-Certified Quality – Rigorous testing ensures low friction, high load capacity & extended service life.

✅ Fast & Reliable Delivery – Optimized production for bulk wholesale orders without delays.

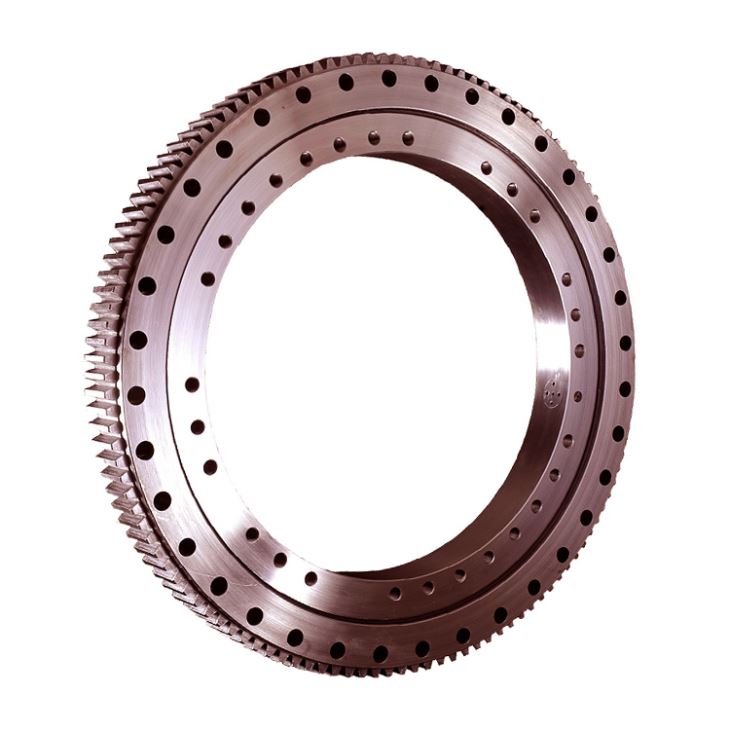

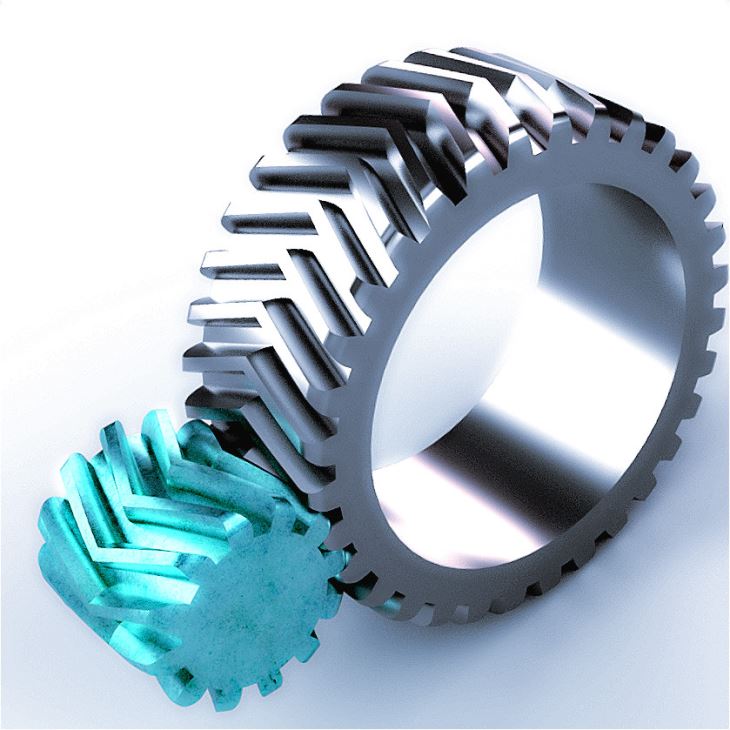

✅ Customized OEM/ODM Solutions – Modify sizes, materials (stainless steel, ceramic), and seals to fit unique applications.

✅ Cost-Effective Sourcing – Eliminate middlemen with direct pricing from our factory.

Solve Common Bearing Procurement Challenges

Many suppliers compromise on quality or lead times. Raydafon guarantees:

✔ Zero Defects – Precision grinding and heat treatment for consistent performance.

✔ Shorter Lead Times – 30% faster production than industry standards.

✔ Flexible Customization – Modify tolerances, lubrication, and coatings per your requirements.

Industries We Serve

Our bearings are trusted in:

✔ Automotive ✔ Aerospace ✔ Heavy Machinery ✔ Robotics ✔ Renewable Energy

Global Procurement Made Simple – Raydafon has supplied OEM/ODM bearings to distributors in the EU, North America, and Asia for over a decade.

Ready to Buy? Partner with a Trusted Bearing Supplier

📞 Contact Raydafon today – Request a free sample or customized quote.

📦 Wholesale discounts available for bulk orders – Fast shipping worldwide.