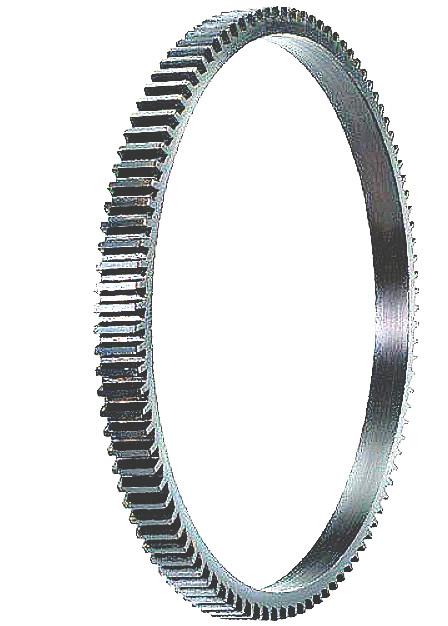

Ring Gears

Ring Gears: Precision Engineering for Industrial Applications

Ring gears are essential components in various mechanical systems, providing smooth rotational motion and torque transmission. Our high-quality ring gears are manufactured to exacting standards, ensuring durability and performance in demanding applications.

Key Features of Our Ring Gears

- Precision-machined teeth for optimal gear meshing

- High-strength materials including alloy steel and hardened steel

- Customizable sizes from small diameter (50mm) to large (3000mm+)

- Multiple tooth profiles including spur, helical, and bevel configurations

- Surface treatments available (heat treatment, carburizing, nitriding)

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Material | 1045 Steel, 4140 Steel, 8620 Steel, Cast Iron |

| Module Range | 1-30 |

| Precision Grade | DIN 5-8, AGMA 10-13, JIS 0-2 |

| Hardness | HRC 45-62 (after heat treatment) |

| Surface Finish | Ra 0.8-3.2μm |

| Inner Diameter Tolerance | H7-H9 |

FAQ Section

1. What are the main applications of Ring Gears?

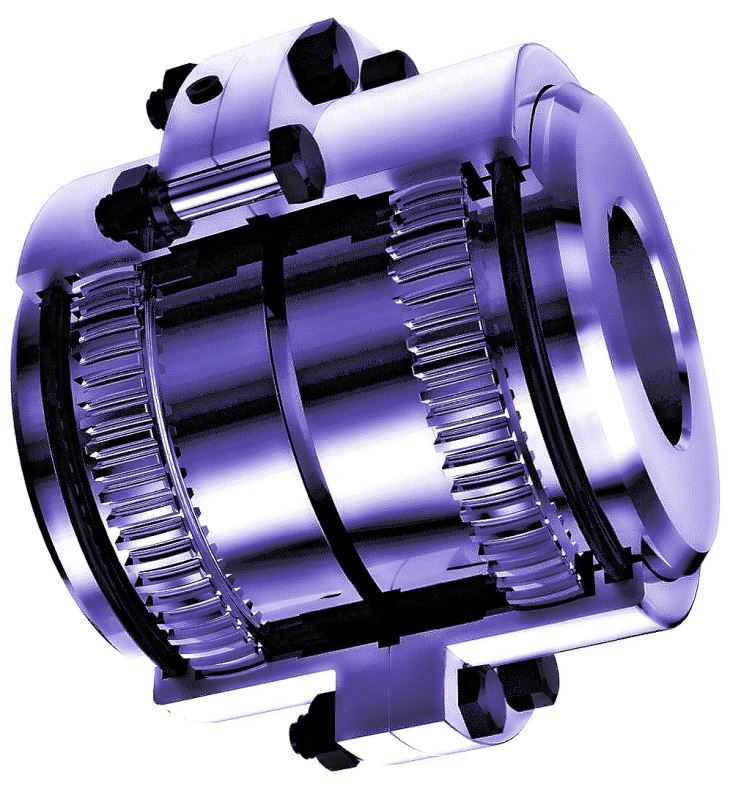

Ring gears are widely used in industrial machinery including wind turbines, mining equipment, construction machinery, marine propulsion systems, and heavy-duty transmissions. Their robust design makes them ideal for applications requiring high torque transmission and durability under extreme conditions.

2. How do I select the right Ring Gear for my application?

Selection depends on several factors: required torque capacity, operating speed, environmental conditions, and space constraints. Consider the module (tooth size), material strength, heat treatment requirements, and precision grade needed for your specific application. Our engineering team can assist with calculations to ensure optimal performance.

Performance Data

| Material | Tensile Strength (MPa) | Fatigue Limit | Maximum Operating Temp |

|---|---|---|---|

| 1045 Steel | 585 | 280 MPa | 400°C |

| 4140 Steel | 850 | 450 MPa | 550°C |

| 8620 Steel | 780 | 380 MPa | 500°C |

Customization Options

We offer comprehensive customization for ring gears:

- Special tooth profiles (modified involute, circular arc)

- Various mounting configurations (flanged, web-type, split design)

- Surface coatings (zinc plating, black oxide, nickel plating)

- Non-standard bore shapes (keyways, splines, special profiles)

- Special tolerances for high-precision applications

FAQ Section

3. What maintenance do Ring Gears require?

Proper maintenance includes regular lubrication with appropriate gear oil, periodic inspection for wear or damage, and alignment checks. For harsh environments, more frequent lubrication may be required. We recommend replacing ring gears when tooth wear exceeds 10% of the original profile or when pitting covers more than 30% of the working surface.

Quality Assurance

All our ring gears undergo rigorous quality control:

- 100% dimensional inspection with CMM

- Material certification (mill test reports)

- Hardness testing (Rockwell and Brinell methods)

- Gear inspection (profile, lead, pitch deviation)

- NDT testing (MPI, ultrasonic) for critical applications

FAQ Section

4. What's the lead time for custom Ring Gears?

Standard ring gears typically ship within 2-4 weeks. Custom designs may require 6-8 weeks depending on complexity. For urgent requirements, expedited manufacturing services are available with a 20-30% surcharge, reducing lead times to 3-4 weeks for custom designs.

5. Can Ring Gears be repaired if damaged?

Minor damage can often be repaired by grinding or re-machining teeth, but this depends on the extent of damage and material condition. Severe pitting, cracks, or tooth breakage usually requires replacement. We offer repair assessment services to evaluate if restoration is feasible for your specific gear.

Industry Standards Compliance

Our ring gears meet or exceed:

- AGMA 2000, 2015 standards

- DIN 3960-3967 specifications

- ISO 1328-1:2013 requirements

- JIS B 1702 standards

- Custom specifications for OEM applications

Conclusion

Our ring gears represent the perfect combination of precision engineering and durable construction. With extensive customization options and strict quality control, we provide solutions for the most demanding industrial applications. Contact our engineering team to discuss your specific requirements and receive expert recommendations for your gear transmission needs.