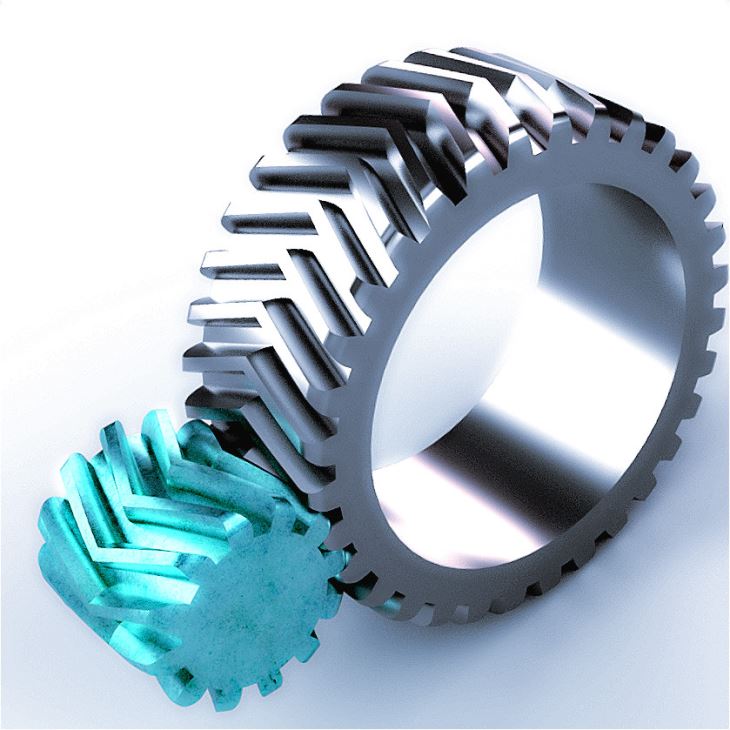

Herringbone Gears

High-Performance Herringbone Gears for Industrial Applications

Herringbone gears, also known as double helical gears, represent the pinnacle of power transmission technology with their unique V-shaped tooth design. Our precision-engineered herringbone gears deliver unmatched performance in heavy-duty applications where noise reduction, load capacity, and smooth operation are critical requirements.

Key Technical Specifications

- Material: Premium alloy steel (AISI 4140/4340), case hardened for durability

- Module Range: 1.5 to 20 module

- Pressure Angle: 20° standard (14.5° and 25° available upon request)

- Helix Angle: 15° to 45° (optimized for specific applications)

- Precision Grade: DIN 3 to 8 (AGMA 10 to 15 equivalent)

- Surface Finish: 0.4-0.8μm Ra after precision grinding

- Maximum Diameter: 2500mm (98.5 inches)

- Heat Treatment: Carburizing, quenching, and tempering to HRC 58-62

Performance Comparison Table

| Feature | Standard Helical | Herringbone Gears | Improvement |

|---|---|---|---|

| Load Capacity | 100% (Baseline) | 140-160% | 40-60% increase |

| Noise Level | 80 dB | 65 dB | 15 dB reduction |

| Axial Thrust | Present | Eliminated | 100% improvement |

| Power Transmission Efficiency | 94-96% | 97-99% | 3-5% improvement |

Herringbone Gears Manufacturing Capabilities

| Gear Type | Diameter Range | Weight Capacity | Max RPM |

|---|---|---|---|

| Parallel Shaft | 50-2000mm | Up to 5000kg | 10,000 |

| Right Angle | 100-1500mm | Up to 3000kg | 7,500 |

| Planetary Systems | 20-800mm | Up to 2000kg | 15,000 |

Herringbone Gears FAQ Section

What are the main advantages of herringbone gears over conventional gears?

Herringbone gears offer three primary advantages: elimination of axial thrust that plagues single helical designs, significantly increased load-bearing capacity due to the double-helix tooth pattern, and remarkably quiet operation. The V-shaped tooth configuration essentially cancels out axial forces while maintaining all the benefits of helical gear engagement. This makes them ideal for high-torque applications in industries like marine propulsion, steel mills, and power generation where reliability is paramount.

How do herringbone gears handle misalignment compared to other gear types?

Herringbone gears have superior misalignment tolerance compared to spur gears but slightly less than single helical designs. The symmetrical tooth pattern provides moderate self-aligning capability (typically ±0.5° angular misalignment). For applications requiring greater misalignment accommodation, we recommend using specially designed crowned herringbone gears which can handle up to ±1.5° misalignment while maintaining optimal contact patterns.

What maintenance considerations are specific to herringbone gears?

Herringbone gears require specialized maintenance protocols. Unlike single helical gears that can be inspected from one side, herringbone designs need mirror-image inspection of both helices. Lubrication systems must be precisely engineered to ensure equal oil distribution to both tooth flanks. We recommend vibration analysis every 500 operating hours and full profile inspection every 2,000 hours for critical applications. Proper break-in procedures (gradual load increase over 50-100 hours) are essential to achieve optimum surface conformity.

Customization Options

Our herringbone gears can be fully customized to meet your specific application requirements:

With over two decades of experience in precision gear manufacturing, our herringbone gears are trusted by Fortune 500 companies across five continents for their exceptional quality and reliability. Contact our engineering team today to discuss your specific power transmission requirements.