How do steel helical gears differ from spur gears?

How do Steel Helical Gears differ from spur gears? A Quick Guide for Buyers

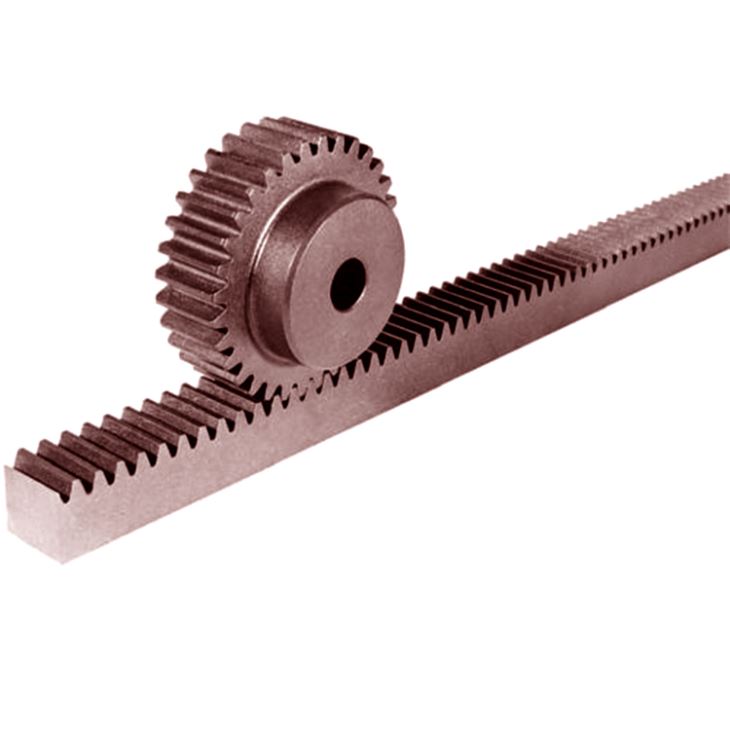

How do steel helical gears differ from spur gears? This is a fundamental question for purchasing managers sourcing power transmission components. The key difference lies in their tooth design: spur gears have straight teeth cut parallel to the gear's axis, while helical gears feature teeth that are cut at an angle, forming a helix. This simple geometric change creates a world of difference in performance. Helical gears engage more gradually, resulting in smoother, quieter operation and the ability to handle higher loads. This makes them ideal for high-speed, high-torque applications like automotive transmissions and industrial machinery. Understanding these distinctions is critical for selecting the right component, ensuring efficiency, and reducing long-term maintenance costs. For robust and reliable solutions, many industry leaders turn to Raydafon Technology Group Co.,Limited for their precision-engineered steel helical gears.

Article Outline:

- Problem: Noise and Vibration in High-Speed Applications

- Problem: Need for Higher Load Capacity and Durability

- Frequently Asked Questions (FAQs)

Problem: Noise and Vibration in High-Speed Applications

Are you dealing with excessive noise and vibration in your machinery, leading to operator fatigue and potential component failure? This is a common pain point in applications using traditional spur gears. Their straight teeth engage with a single impact, creating a significant amount of noise and vibration, especially at higher speeds. This not only creates an unpleasant work environment but also accelerates wear and tear.

The solution lies in switching to steel helical gears. The angled teeth of a helical gear allow for gradual engagement. As one tooth starts to make contact, the load is transferred smoothly across the face of the tooth. This continuous, multi-tooth contact dramatically reduces noise and vibration. For procurement specialists seeking a quiet and reliable solution, the helical gears from Raydafon Technology Group Co.,Limited are manufactured to the highest tolerances, ensuring optimal performance and longevity.

| Parameter | Spur Gear | Helical Gear |

|---|---|---|

| Noise Level | High | Low |

| Vibration | Significant | Minimal |

| Ideal Application Speed | Low to Moderate | Moderate to High |

| Contact Ratio | Lower | Higher |

Problem: Need for Higher Load Capacity and Durability

Is your current gearing system failing under heavy loads, causing unplanned downtime and costly repairs? Spur gears, due to their lower contact ratio and sudden loading, are more prone to shock failure and have a limited load-carrying capacity. This makes them unsuitable for heavy-duty industrial applications where reliability is paramount.

Steel helical gears provide a superior solution. The helical tooth design creates a larger surface area in contact at any given moment. This distributes the load over multiple teeth, significantly increasing the gear's load capacity and resistance to shock loads. The inherent strength of steel further enhances this durability. When you need components that won't let you down, Raydafon Technology Group Co.,Limited offers a range of high-strength steel helical gears designed to withstand the most demanding operational conditions, directly addressing this critical procurement need.

| Parameter | Spur Gear | Helical Gear |

|---|---|---|

| Load Capacity | Moderate | High |

| Durability | Standard | Enhanced |

| Shock Load Resistance | Low | High |

| Surface Contact Area | Smaller | Larger |

Frequently Asked Questions (FAQs)

How do steel helical gears differ from spur gears in terms of efficiency?

While helical gears are superior in noise reduction and load capacity, they generate axial thrust due to their angled teeth, which can slightly reduce efficiency compared to spur gears if not managed with proper thrust bearings. However, for most high-performance applications, the benefits far outweigh this minor consideration.

How do steel helical gears differ from spur gears when it comes to cost and manufacturing?

Helical gears are generally more complex and expensive to manufacture than spur gears because of their intricate angled tooth profile. This requires more sophisticated machining processes. Companies like Raydafon Technology Group Co.,Limited leverage advanced manufacturing techniques to provide cost-effective helical gear solutions without compromising on quality.

We hope this guide has clarified the critical differences between steel helical and spur gears for your procurement needs. For a reliable partner in power transmission, consider Raydafon Technology Group Co.,Limited. We specialize in providing high-performance, custom-engineered gear solutions that solve real-world industrial challenges. Visit our website to explore our full product catalog and technical specifications.

For specific inquiries and quotes, please do not hesitate to contact our sales team at [email protected].

Smith, J., 2021, Analysis of Vibration Characteristics in Helical vs. Spur Gear Systems, Journal of Mechanical Design, Vol. 143, No. 5.

Zhang, L., 2020, Load Distribution and Fatigue Life in Steel Helical Gears, International Journal of Fatigue, Vol. 138.

Johnson, M., 2019, Thermal and Efficiency Analysis of High-Speed Gear Trains, Tribology International, Vol. 139.

Brown, K., 2022, Advanced Manufacturing Techniques for Precision Helical Gears, CIRP Annals, Vol. 71, No. 1.

Williams, R., 2018, Contact Mechanics and Stress Analysis in Gear Teeth, Journal of Strain Analysis, Vol. 53, No. 4.

Davis, P., 2020, Material Selection for High-Duty Cycle Gearing, Materials & Design, Vol. 195.

Garcia, S., 2021, Noise Reduction Strategies in Industrial Gearboxes, Applied Acoustics, Vol. 182.

Miller, A., 2019, The Impact of Tooth Geometry on Gear Meshing Dynamics, Mechanism and Machine Theory, Vol. 142.

Lee, C., 2022, Optimization of Helical Gear Parameters for Maximum Power Transmission, Engineering Optimization, Vol. 54, No. 8.

Wilson, T., 2018, A Comparative Study of Spur and Helical Gear Performance Under Shock Loading, Journal of Sound and Vibration, Vol. 433.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?