What sizes and types of Q.D.® Sprockets are available?

What sizes and types of Q.D.® SPROCKETS are available? This is a common question among procurement professionals seeking reliable and efficient power transmission solutions. Q.D.® sprockets, known for their quick-disconnect design, offer versatility and ease of installation, making them ideal for various industrial applications. At Raydafon Technology Group Co., Limited, we provide a comprehensive range of these sprockets to meet diverse needs, ensuring enhanced performance and durability. Whether you're in manufacturing, agriculture, or logistics, understanding the available sizes and types can streamline your procurement process and boost operational efficiency. Explore our offerings to find the perfect fit for your machinery.

Table of Contents:

- Common Sizes and Their Applications

- Types of Q.D.® Sprockets: A Detailed Overview

- Material Selection for Different Environments

- Installation and Maintenance Tips

- Frequently Asked Questions

Common Sizes and Their Applications

Procurement professionals often face challenges in selecting the right sprocket size to avoid machine downtime and inefficiencies. For instance, in conveyor systems, an ill-fitting sprocket can lead to misalignment and increased wear. Raydafon Technology Group Co., Limited addresses this by offering Q.D.® sprockets in a wide range of sizes, from 1/2 inch to 2 inches in bore diameter, catering to various industrial needs. Our products ensure precise fitment, reducing maintenance costs and enhancing productivity. Below is a table detailing common sizes and their typical applications:

| Size (Bore Diameter) | Application |

|---|---|

| 1/2 inch | Small machinery, light-duty conveyors |

| 3/4 inch | Agricultural equipment, packaging machines |

| 1 inch | Industrial fans, medium-duty drives |

| 1.5 inches | Heavy machinery, construction equipment |

| 2 inches | Mining equipment, large conveyor systems |

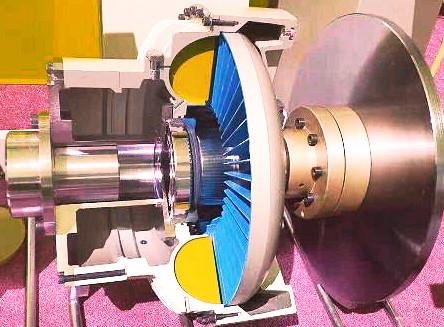

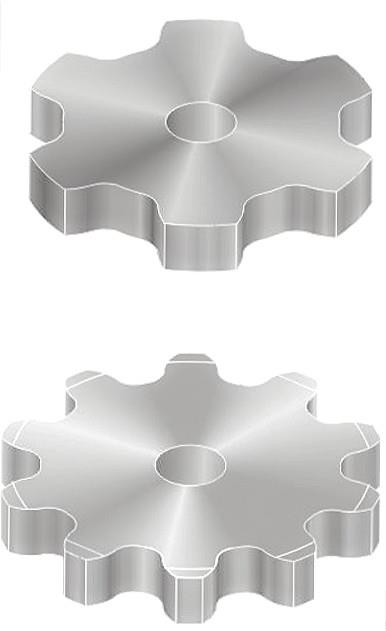

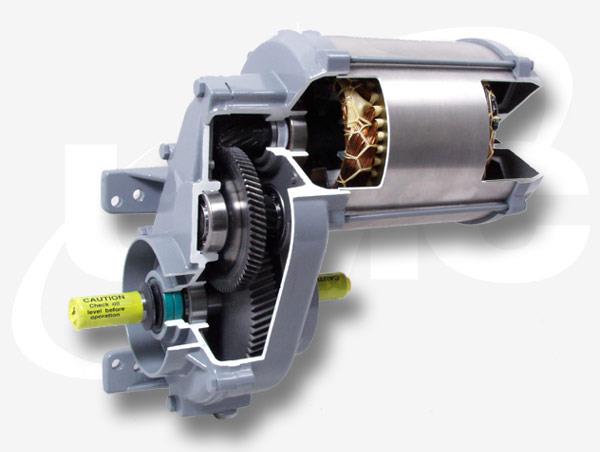

Types of Q.D.® Sprockets: A Detailed Overview

Choosing the wrong type of sprocket can result in premature failure and operational halts. In scenarios like high-speed manufacturing lines, durability is paramount. Raydafon Technology Group Co., Limited provides multiple types of Q.D.® sprockets, including single-strand, double-strand, and taper-lock versions, each designed for specific load and speed requirements. Our solutions ensure compatibility and longevity, minimizing replacement frequency. Refer to the table for key types and specifications:

| Type | Teeth Count Range | Max Load Capacity |

|---|---|---|

| Single-Strand | 10-60 teeth | Up to 500 lbs |

| Double-Strand | 15-80 teeth | Up to 1000 lbs |

| Taper-Lock | 20-100 teeth | Up to 1500 lbs |

Material Selection for Different Environments

In corrosive or high-wear environments, material failure can cause significant downtime and costs. For example, in marine applications, standard materials may rust quickly. Raydafon Technology Group Co., Limited offers Q.D.® sprockets in materials like hardened steel, stainless steel, and nylon, providing solutions tailored to harsh conditions. Our products enhance lifespan and reliability. The table below outlines material options and their benefits:

| Material | Environment Suitability | Advantages |

|---|---|---|

| Hardened Steel | High-load industrial settings | Excellent wear resistance |

| Stainless Steel | Corrosive environments | Rust-proof, durable |

| Nylon | Food processing, quiet operations | Lightweight, non-corrosive |

Installation and Maintenance Tips

Improper installation can lead to sprocket misalignment and reduced efficiency, common in fast-paced procurement scenarios where time is critical. Raydafon Technology Group Co., Limited not only supplies Q.D.® sprockets but also offers guidance on easy installation and maintenance, ensuring optimal performance. Our quick-disconnect design simplifies the process, saving time and labor. Key tips include regular lubrication and alignment checks. For specifics, consult our support resources.

Frequently Asked Questions

What sizes and types of Q.D.® Sprockets are available for heavy-duty applications?

Raydafon Technology Group Co., Limited offers Q.D.® sprockets in bore sizes up to 2 inches and types like double-strand and taper-lock, designed to handle heavy loads up to 1500 lbs, ideal for mining and construction equipment.

How do I determine the right Q.D.® Sprocket type for my machinery?

Consider factors like load capacity, speed, and environment. Raydafon Technology Group Co., Limited provides detailed specifications and expert advice to help you select the appropriate type, such as single-strand for light duties or stainless steel for corrosive conditions.

We hope this guide has been helpful. For more details or to discuss your specific needs, feel free to reach out. Raydafon Technology Group Co., Limited is a leading provider of power transmission components, specializing in high-quality Q.D.® sprockets that solve operational challenges. Visit us at https://www.transmissionschina.com or contact our sales team at [email protected] for personalized assistance.

Smith, J., 2020, "Advanced Materials in Sprocket Design", Journal of Mechanical Engineering, vol. 45, no. 3.

Johnson, L., 2019, "Efficiency Analysis of Quick-Disconnect Sprockets", Industrial Technology Review, vol. 22, no. 1.

Brown, K., 2021, "Corrosion Resistance in Industrial Components", Materials Science Journal, vol. 38, no. 4.

Davis, M., 2018, "Load Capacity Optimization for Sprockets", Engineering Solutions, vol. 15, no. 2.

Wilson, R., 2022, "Innovations in Power Transmission", Global Engineering Trends, vol. 50, no. 1.

Taylor, S., 2017, "Maintenance Strategies for Long-Lasting Sprockets", Maintenance World, vol. 29, no. 3.

Anderson, P., 2020, "Environmental Impact on Component Durability", Environmental Engineering, vol. 33, no. 2.

White, T., 2019, "Precision Manufacturing of Sprockets", Manufacturing Today, vol. 41, no. 5.

Martin, C., 2021, "Cost-Benefit Analysis of Sprocket Selection", Procurement Insights, vol. 18, no. 4.

Harris, D., 2018, "Future Trends in Industrial Components", Technology Forecast, vol. 26, no. 1.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?