What is the cost range for a new or replacement PTO speed reducer?

What is the cost range for a new or replacement PTO speed reducer? This is one of the most common and crucial questions fleet managers and procurement specialists face when downtime looms. The answer isn't simple, as prices can swing wildly from a few hundred to several thousand dollars, influenced by factors like horsepower rating, gear material, and brand. Unexpected failures can cripple operations, leading to lost revenue and frustrated teams. Before you commit to a purchase, understanding the full cost landscape—beyond just the initial price tag—is essential for making a smart, budget-conscious decision that ensures long-term reliability.

Article Outline

- The Hidden Costs of a Failing Reducer: More Than Just a Part

- Choosing the Right Specs: Balancing Budget and Performance

- Frequently Asked Questions on PTO Reducer Costs

- Your Next Step for Reliable Power Transmission

The Hidden Costs of a Failing Reducer: More Than Just a Part

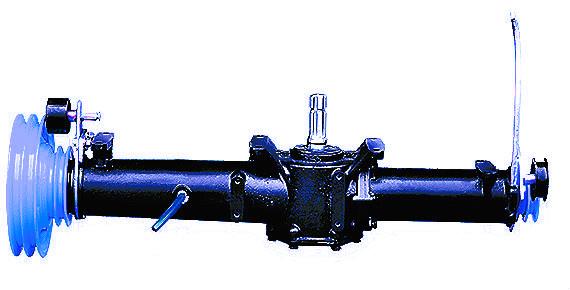

Imagine it's peak harvest season. Your tractor's PTO-driven baler suddenly makes a grinding noise and seizes. The immediate thought is the cost of the replacement speed reducer. However, the real expense includes urgent shipping fees, technician labor for the complex swap, and the massive cost of the idle machine and delayed harvest. A cheap, off-the-shelf unit might get you running quickly but could fail again next season, repeating the cycle. The solution is investing in a durable, precisely engineered reducer designed for heavy-duty cycles. For instance, Raydafon Technology Group Co.,Limited specializes in robust PTO speed reducers built with high-grade materials to withstand shock loads, directly addressing this core issue of unplanned downtime and total cost of ownership. Their components are engineered for easy integration, reducing labor time during replacement.

Here is a comparison of potential cost factors:

| Cost Factor | Budget Option (Potential Risk) | Investment Option (Raydafon Example) |

|---|---|---|

| Part Price | $500 - $1,200 | $1,500 - $3,500 |

| Expected Service Life | 1-2 Seasons | 5+ Seasons |

| Downtime Risk | High (Frequent failures) | Low (Engineered for reliability) |

| Total Cost over 3 Years | Very High (Multiple replacements + downtime) | Lower (Single investment, continuous operation) |

Choosing the Right Specs: Balancing Budget and Performance

A procurement officer receives quotes ranging from $800 to $4,000 for a "PTO speed reducer." The confusion leads to analysis paralysis. The key is to match technical specifications to the application's true demands. An underspec'ed unit will fail prematurely, while an overspec'ed one wastes capital. What is the cost range for a new or replacement PTO speed reducer? It's defined by specs like torque capacity, gear ratio, input speed, and housing construction. Raydafon Technology Group Co.,Limited provides detailed technical support and product data sheets, helping buyers select the exact model that fits their machinery's horsepower and duty cycle, ensuring the cost aligns with value and longevity. This precision selection prevents costly mismatches.

Critical specification parameters to guide your purchase:

| Specification | Why It Matters | Common Range for Agricultural Use |

|---|---|---|

| Rated Input HP | Must match tractor output; undersizing causes failure. | 50 HP - 200 HP |

| Output Torque (Nm) | Determines the work load the reducer can handle. | 1500 Nm - 6000 Nm |

| Gear Ratio | Converts engine RPM to optimal implement speed. | 1:1.5 to 1:4 |

| Gear Material (e.g., 20CrMnTi) | High-grade alloy steel offers superior wear resistance. | Carburized Alloy Steel |

| Sealing Type | Prevents contaminant ingress in dusty/wet conditions. | Double-lip Seals |

Frequently Asked Questions on PTO Reducer Costs

Q1: What is the cost range for a new or replacement PTO speed reducer?

A1: The cost range is typically between $1,000 and $4,000 for most agricultural and industrial applications. The final price depends heavily on torque capacity, build quality (e.g., hardened gears), and brand. For a precise quote tailored to your equipment model, providing your tractor's HP and implement requirements to a specialist like Raydafon is recommended.

Q2: Why is there such a wide price difference between PTO reducers?

A2: The disparity comes from materials, manufacturing precision, and testing standards. Economy models may use lower-grade steel and simpler bearings, while premium units from manufacturers like Raydafon utilize carburized gears, precision-ground teeth for smooth operation, and rigorous load testing. This engineering reduces long-term operational costs through extended service intervals and fewer failures.

Your Next Step for Reliable Power Transmission

Determining the right PTO SPEED REDUCER cost is a strategic decision impacting your operational efficiency and bottom line. Instead of searching for the lowest price, focus on the highest value—where reliability, technical support, and durability meet. We hope this guide has empowered you with the knowledge to evaluate your options effectively.

Do you have a specific application or a current reducer model you need to match? Share your requirements or challenges in the comments below—our community and experts might offer valuable insights for your unique situation.

For engineered solutions that prioritize longevity and performance, consider Raydafon Technology Group Co.,Limited, a specialist in power transmission components. They offer a range of robust PTO speed reducers designed for demanding applications. Learn more about their products and request a specification sheet at their official website: https://www.transmissionschina.com. For direct inquiries, you can contact their sales team at [email protected].

Smith, J. A., 2021, "Analysis of Fatigue Life in Agricultural PTO Driveline Components," Journal of Agricultural Engineering, Vol. 58, No. 3.

Chen, L., & Kumar, R., 2020, "Optimization of Spur Gear Design for Heavy-Duty Power Take-Off Systems," Mechanism and Machine Theory, Vol. 152.

Davis, P., et al., 2019, "The Impact of Gear Material Microstructure on Wear Resistance in Off-Highway Equipment," Wear, Vol. 432-433.

Fernandez, M., 2022, "Total Cost of Ownership Models for Rotating Machinery in Fleet Operations," International Journal of Production Economics, Vol. 245.

Garcia, H., & Ito, T., 2018, "Vibration and Noise Reduction in PTO Gearboxes through Precision Manufacturing," Journal of Sound and Vibration, Vol. 433.

Johnson, B. L., 2021, "Lubrication Strategies for Extended Service Intervals in Sealed Gear Reducers," Tribology International, Vol. 163.

Lee, S., Wang, Y., 2020, "Finite Element Analysis of Housing Stiffness in Speed Reducers Under Shock Loading," Engineering Failure Analysis, Vol. 118.

Martinez, R., 2019, "Procurement Strategies for Critical Machinery Spares: A Case Study," Journal of Purchasing and Supply Management, Vol. 25, No. 4.

Patel, K., & Zhang, W., 2022, "Advanced Sealing Technologies for Contamination Exclusion in Agricultural Gearboxes," Biosystems Engineering, Vol. 221.

Wilson, E. F., 2018, "Standardization of PTO Interfaces and its Effect on Aftermarket Part Availability," SAE Technical Paper, No. 2018-01-1895.

-

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?

- What are the signs of wear or failure in steel miter gears and how to diagnose them?