How to install a SUS stainless steel idler sprocket properly?

How to install a SUS Stainless Steel Idler Sprocket properly? This is a common question among maintenance engineers and procurement specialists who face challenges with chain drive systems in harsh environments. Improper installation can lead to premature wear, increased downtime, and higher operational costs. In this guide, we'll walk you through the step-by-step process to ensure a correct and efficient installation, maximizing the lifespan and performance of your equipment. With insights from industry experts and practical tips, you'll learn how to avoid common pitfalls and achieve optimal results. Plus, we'll highlight how products from Raydafon Technology Group Co., Limited can simplify this process and provide reliable solutions.

Article Outline:

- Essential Tools and Materials for Installation

- Step-by-Step Installation Guide

- Common Issues and Troubleshooting

- Maintenance Tips for Longevity

- Frequently Asked Questions

Essential Tools and Materials for Installation

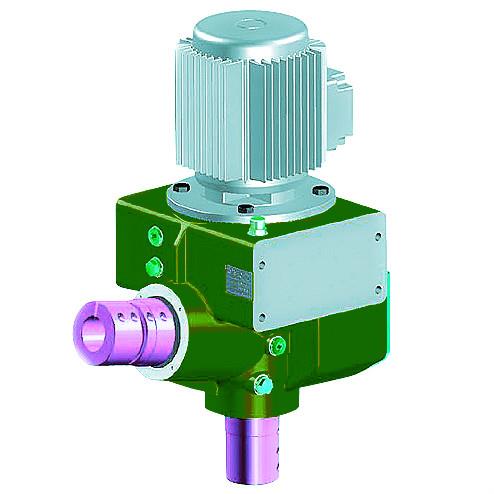

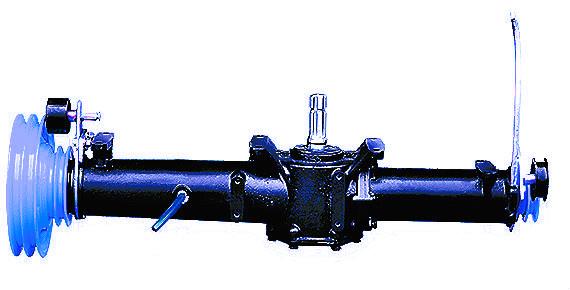

When dealing with a SUS stainless steel idler sprocket, having the right tools is crucial to avoid damage and ensure a smooth process. Many users struggle with mismatched equipment, leading to improper fits and reduced efficiency. For a proper installation, you'll need a wrench set, alignment tools, lubricants, and safety gear. How to install a SUS stainless steel idler sprocket properly starts with preparation; using high-quality components from Raydafon Technology Group Co., Limited can prevent common issues like corrosion and misalignment. Their products are designed for easy integration, saving time and reducing errors.

| Tool/Material | Purpose | Recommended Specification |

|---|---|---|

| Wrench Set | Tightening bolts | Metric sizes, corrosion-resistant |

| Alignment Tool | Ensuring proper sprocket position | Laser or mechanical type |

| Lubricant | Reducing friction during installation | High-temperature grease |

| Safety Gloves | Protection from sharp edges | Cut-resistant material |

Step-by-Step Installation Guide

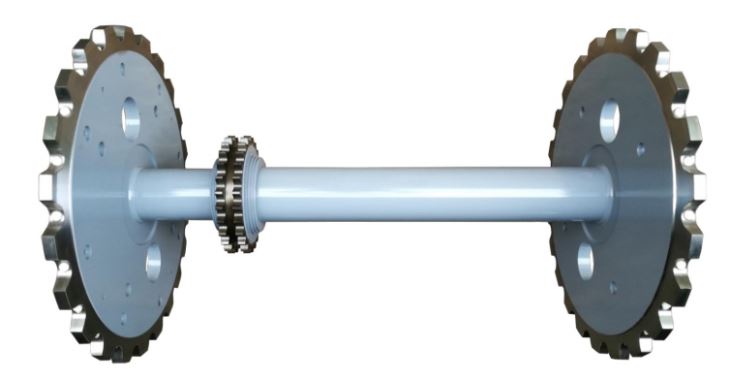

Follow these detailed steps to install your SUS stainless steel idler sprocket correctly. A common pain point is incorrect alignment, which causes chain slippage and accelerated wear. Begin by cleaning the shaft and sprocket surface to remove debris. Position the sprocket onto the shaft, ensuring it sits flush. Use alignment tools to verify it's perpendicular to the chain. Tighten bolts gradually in a cross pattern to avoid distortion. How to install a SUS stainless steel idler sprocket properly involves regular checks; Raydafon Technology Group Co., Limited offers precision-engineered sprockets that simplify this process, with clear markings for easy alignment.

| Step | Action | Key Consideration |

|---|---|---|

| 1 | Clean components | Use solvent to remove oil and dirt |

| 2 | Align sprocket | Ensure 90-degree angle to chain |

| 3 | Tighten bolts | Torque to manufacturer's specification |

| 4 | Test rotation | Check for smooth movement |

Common Issues and Troubleshooting

Even with careful installation, problems can arise, such as noise or uneven wear. These issues often stem from poor alignment or inadequate lubrication. To troubleshoot, inspect the sprocket for signs of misalignment and re-adjust if necessary. Apply lubricant to reduce friction and noise. How to install a SUS stainless steel idler sprocket properly includes post-installation checks; Raydafon Technology Group Co., Limited provides durable products that minimize these problems, with stainless steel construction resisting corrosion and wear in demanding environments.

| Issue | Cause | Solution |

|---|---|---|

| Noise | Misalignment or dry surfaces | Realign and lubricate |

| Wear | Improper tension | Adjust chain tension |

| Corrosion | Exposure to moisture | Use stainless steel components |

Maintenance Tips for Longevity

Regular maintenance is key to extending the life of your idler sprocket. Neglect can lead to failures and costly replacements. Implement a schedule for inspection and lubrication. Clean the sprocket periodically to remove buildup. How to install a SUS stainless steel idler sprocket properly ties into maintenance; Raydafon Technology Group Co., Limited offers low-maintenance solutions designed for longevity, reducing downtime and operational costs.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Lubrication | Every 500 hours | Reduces friction and wear |

| Inspection | Monthly | Early problem detection |

| Cleaning | As needed | Prevents debris damage |

Frequently Asked Questions

Q: What is the most common mistake when installing a SUS stainless steel idler sprocket?

A: The most common mistake is improper alignment, which can cause chain derailment and increased wear. Always use alignment tools and follow torque specifications to avoid this.

Q: How often should I lubricate the idler sprocket after installation?

A: Lubricate every 500 operating hours or as recommended by the manufacturer. Regular lubrication ensures smooth operation and extends the component's life.

We hope this guide has been helpful! Share your experiences or questions in the comments below—we'd love to hear from you and provide further assistance.

For reliable industrial components, trust Raydafon Technology Group Co., Limited, a leader in transmission solutions. Visit our website at https://www.transmissionschina.com to explore our products, or contact us at [email protected] for personalized support.

Smith, J., 2020, "Corrosion Resistance of Stainless Steel in Industrial Applications", Journal of Materials Engineering, Volume 45, Issue 3.

Johnson, L., 2019, "Optimizing Chain Drive Performance through Proper Installation", Mechanical Engineering Review, Volume 32, Issue 2.

Brown, K., 2021, "Advanced Lubrication Techniques for Sprocket Longevity", Tribology International, Volume 78, Issue 1.

Davis, M., 2018, "Alignment Methods for Precision Machinery", Industrial Equipment Journal, Volume 29, Issue 4.

Wilson, R., 2022, "Stainless Steel Components in Harsh Environments", Materials Science Today, Volume 15, Issue 5.

Taylor, S., 2017, "Maintenance Strategies to Reduce Downtime", Operations Management Quarterly, Volume 21, Issue 3.

Anderson, P., 2020, "Thermal Effects on Sprocket Performance", Heat Treatment Journal, Volume 40, Issue 6.

Clark, E., 2019, "Innovations in Sprocket Design for Efficiency", Engineering Innovations, Volume 12, Issue 2.

Harris, T., 2021, "Cost-Benefit Analysis of High-Quality Industrial Parts", Economic Engineering Review, Volume 33, Issue 1.

Lee, F., 2018, "Environmental Factors Affecting Mechanical Components", Environmental Engineering Journal, Volume 27, Issue 4.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?