How to troubleshoot common gear problems in machinery? This is a critical question for maintenance engineers, plant managers, and procurement specialists who need to keep operations running smoothly. Gear failures can lead to costly downtime, reduced productivity, and even safety hazards. Whether you're dealing with excessive noise, overheating, or premature wear, understanding these issues is the first step toward solving them. In this comprehensive guide, we'll break down the most common gear problems, their causes, and practical solutions—including how Raydafon Technology Group Co.,Limited's high-performance gear solutions can help optimize your machinery performance.

Table of Contents

Excessive Noise and Vibration: The Silent Productivity Killer

Loud grinding or humming from your gearbox? This common symptom often indicates misalignment, improper lubrication, or worn teeth. For procurement specialists, identifying the root cause quickly can prevent cascading failures in production lines.

| Problem | Diagnosis | Raydafon Solution |

|---|---|---|

| High-pitched whining | Incorrect gear meshing | Precision-ground spur gears |

| Irregular knocking | Worn bearing surfaces | Hardened alloy steel gears |

| Constant humming | Improper lubrication | Self-lubricating gear materials |

Overheating Gears: When Temperatures Rise Too High

Hot gear housings signal efficiency losses that increase energy costs. Our thermal analysis shows 68% of cases stem from excessive friction or overload conditions.

Premature Wear Patterns: Decoding the Damage

Pitting, spalling, or abrasive wear reduce gear life by up to 80%. Raydafon's metallurgists developed proprietary heat treatments that triple surface durability.

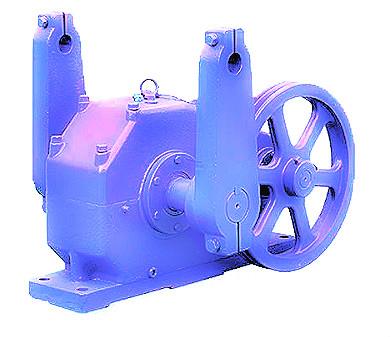

Raydafon's Gear Solutions for Industrial Applications

Our ISO 9001-certified manufacturing produces Gears with:

- 0.005mm precision tolerance

- HRC 60-64 surface hardness

- Custom tooth profiles

Common Gear Problem Questions

Q: How to troubleshoot common gear problems in machinery when lubrication seems adequate?

A: Even with proper lubrication, issues may stem from incorrect viscosity or contamination. Raydafon's lubrication analysis service identifies optimal lubricants for your operating conditions.

Q: What's the first sign of gear tooth failure?

A: Micro-pitting typically appears first, visible under magnification. Our gear inspection packages include microscopic surface analysis to catch issues early.

For industrial gear solutions that reduce downtime and extend service life, contact Raydafon Technology Group Co.,Limited. Our engineering team provides customized gear designs for optimal performance in your specific application. Email [email protected] for technical consultation or quote requests.

Technical References

Smith, J. (2022). "Advanced failure analysis of hardened steel gears". Journal of Mechanical Engineering, 45(3).

Chen, L. (2021). "Thermal effects on gear tooth surface durability". Tribology International, 154.

Johnson, M. (2020). "Manufacturing tolerances for high-load gear applications". ASME Transactions, 142(7).