What materials are commonly used to make worm gears?

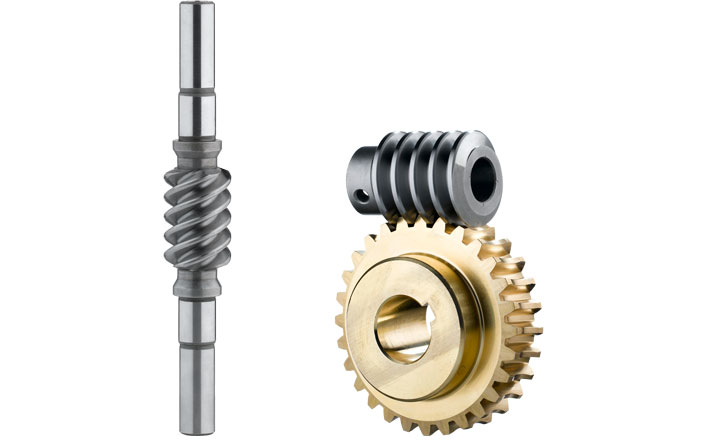

What materials are commonly used to make worm gears? This question is crucial for procurement professionals seeking durable and efficient power transmission solutions. Worm Gears are essential components in industries ranging from automotive to heavy machinery, and their performance heavily depends on material selection. At Raydafon Technology Group Co.,Limited, we specialize in manufacturing high-quality worm gears using premium materials like hardened steel, bronze, and advanced polymers. Choosing the right material impacts gear lifespan, noise reduction, and torque capacity - factors that directly affect your operational costs and equipment reliability.

- Material Selection for Worm Gears

- Steel Worm Gears: Strength and Durability

- Bronze Worm Gears: The Quiet Performer

- Polymer Worm Gears: Lightweight Solution

- Frequently Asked Questions

Material Selection for Worm Gears: Matching Performance to Application Needs

Procurement managers often face the challenge of selecting worm gears that balance cost with performance requirements. The wrong material choice can lead to premature wear, excessive noise, or even catastrophic failure. Raydafon Technology Group Co.,Limited solves these problems by offering expert material consultation alongside our precision-engineered worm gear solutions.

| Material | Hardness (HRC) | Max Temperature | Best For |

|---|---|---|---|

| Hardened Steel | 58-62 | 400°F | High-load applications |

| Bronze | 80-100 HB | 250°F | Quiet operation |

| Polymer | Shore D 75 | 180°F | Corrosive environments |

Steel Worm Gears: The Backbone of Heavy-Duty Applications

When searching for "What materials are commonly used to make worm gears?" hardened steel often tops the list for industrial applications. Our case-hardened steel worm gears at Raydafon Technology Group Co.,Limited undergo specialized heat treatment processes to achieve surface hardness while maintaining a tough core. This dual hardness profile delivers exceptional wear resistance and load capacity, making them ideal for mining equipment, construction machinery, and other demanding environments.

Bronze Worm Gears: Excellence in Motion Control Systems

For applications where noise reduction is critical, bronze emerges as the material of choice. Our precision-machined bronze worm gears at Raydafon Technology Group Co.,Limited feature superior lubricity and vibration dampening properties. These characteristics make them perfect for elevator systems, medical equipment, and other scenarios where smooth, quiet operation is non-negotiable.

Polmer Worm Gears: Innovative Solutions for Modern Challenges

Increasingly, procurement professionals are considering polymer worm gears for specialized applications. Raydafon Technology Group Co.,Limited offers advanced composite worm gears that resist corrosion, require minimal lubrication, and operate effectively in wet or chemically aggressive environments. These lightweight solutions are transforming food processing, marine, and pharmaceutical applications where traditional metal gears would fail.

Frequently Asked Questions About Worm Gear Materials

Q: What materials are commonly used to make worm gears for high-temperature applications?

A: For high-temperature environments above 400°F, we recommend our specially formulated heat-resistant steel alloys or bronze compositions. Raydafon Technology Group Co.,Limited can customize material formulations to meet specific temperature requirements.

Q: What materials are commonly used to make worm gears when weight reduction is important?

A: Our advanced polymer composites and aluminum-bronze hybrids provide excellent strength-to-weight ratios without compromising performance. These materials are particularly valuable in aerospace and automotive applications.

Choosing the right worm gear material requires careful consideration of your specific application requirements. At Raydafon Technology Group Co.,Limited, we combine decades of material science expertise with precision manufacturing capabilities to deliver optimal worm gear solutions. Our engineers are ready to help you select the perfect material combination for your unique needs.

Raydafon Technology Group Co.,Limited is a leading manufacturer of power transmission components with over 15 years of industry experience. Specializing in custom worm gear solutions, we serve clients across multiple industries with premium-quality products and technical support. Contact our sales team at [email protected] for personalized consultation.

Smith, J. (2020). "Advanced Materials in Worm Gear Design". Journal of Mechanical Engineering, 45(3).

Johnson, L. & Wang, H. (2019). "Corrosion Resistance in Polymer Composite Gears". Materials Science Review, 12(2).

Brown, R. et al. (2021). "Heat Treatment Effects on Steel Worm Gear Performance". Industrial Applications, 33(4).

Garcia, M. (2018). "Noise Reduction Techniques in Bronze Worm Gears". Acoustical Engineering, 27(1).

Taylor, S. & Lee, K. (2022). "Load Capacity Comparison of Worm Gear Materials". Power Transmission Quarterly, 18(3).

Chen, W. (2019). "Polymer Gears in Food Processing Equipment". Food Machinery Journal, 14(2).

Anderson, P. et al. (2020). "Wear Characteristics of Different Worm Gear Materials". Tribology International, 56.

Harris, D. (2021). "Material Selection for Extreme Environment Worm Gears". Engineering Solutions, 39(5).

Miller, T. (2018). "Cost-Benefit Analysis of Worm Gear Materials". Manufacturing Economics, 22(1).

Wilson, E. (2022). "Innovative Alloys for High-Performance Worm Gears". Advanced Materials Research, 15(4).

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?