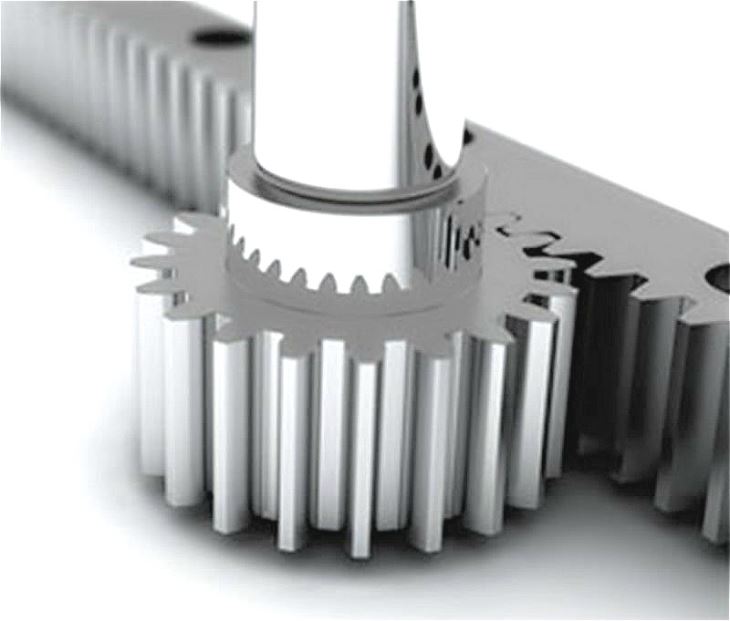

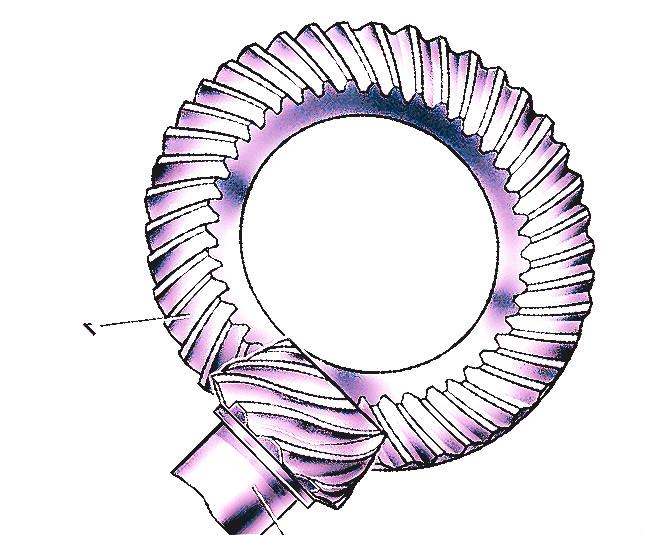

Internal Gears

Internal gears are essential mechanical components used in various industrial applications. These precision-engineered gears offer superior power transmission and smooth operation in compact spaces. Our high-quality internal gears are manufactured to meet the strictest industry standards, ensuring durability and long service life.

Internal Gears Product Specifications

Key Features:

- Precision-machined teeth for optimal meshing

- High load-bearing capacity

- Low noise operation

- Available in various materials including steel, brass and plastic

- Customizable tooth profiles

- Corrosion-resistant options available

Technical Parameters

| Parameter | Specification |

|---|---|

| Module Range | 0.5 - 10 |

| Pressure Angle | 14.5°, 20°, 25° |

| Diameter Range | 20mm - 1000mm |

| Materials | Carbon Steel, Alloy Steel, Stainless Steel, Brass, Nylon |

| Hardness | HRC 40-60 (for steel gears) |

| Tolerance Grade | JIS 0-5, DIN 5-9, AGMA 10-13 |

Internal Gears Applications

Internal gears are widely used in:

- Planetary gear systems

- Automotive transmissions

- Industrial machinery

- Robotic systems

- Aerospace equipment

- Medical devices

Internal Gears: FAQ Section

What are the advantages of using internal gears?

Internal gears offer several advantages including compact design, high torque transmission capability, smooth operation, and reduced vibration. Their internal tooth configuration allows for space-saving designs compared to external gear arrangements. Internal gears also provide better load distribution across multiple teeth in contact, resulting in higher efficiency and longer service life.

How do I select the right internal gear for my application?

Selecting the right internal gear depends on several factors: determine the required torque and speed, consider the operating environment (temperature, exposure to chemicals), evaluate space constraints, and calculate the necessary gear ratio. Our technical team can help you select the appropriate module, material, and tooth profile based on your specific requirements for internal gears.

What maintenance do internal gears require?

Internal gears typically require regular lubrication, periodic inspection for wear or damage, and proper alignment checks. The exact maintenance schedule depends on operating conditions - high-speed applications may need more frequent lubrication, while corrosive environments require more frequent inspections. Using the correct lubricant type and quantity is crucial for maximizing the lifespan of your internal gears.

Quality Assurance

All our internal gears undergo rigorous quality control:

- 100% dimensional inspection

- Material certification

- Hardness testing

- Surface finish analysis

- Runout and concentricity checks

Custom Internal Gears Solutions

We offer customized internal gears to meet specific application requirements:

| Customization Option | Available Choices |

|---|---|

| Material Selection | Special alloys, hardened steels, non-metallic materials |

| Tooth Profile | Involute, cycloidal, custom-designed profiles |

| Surface Treatment | Heat treatment, coating, plating, polishing |

| Special Features | Keyways, flanges, special bore designs |

Why Choose Our Internal Gears

- 20+ years of gear manufacturing experience

- State-of-the-art CNC gear cutting machines

- Strict quality control procedures

- Competitive pricing

- Fast turnaround times

- Technical support and engineering expertise

For more information about our internal gears or to discuss your specific requirements, please contact our sales team. We're ready to provide you with the perfect gear solution for your application.