How to maintain and extend the life of cast iron sprockets?

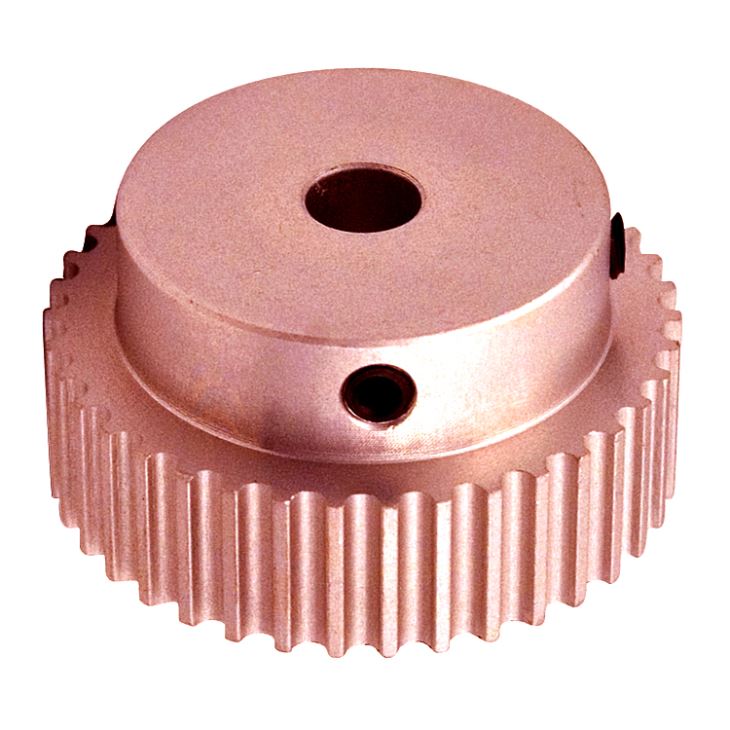

How to maintain and extend the life of cast iron sprockets? This is a critical question for industries relying on heavy machinery and conveyor systems. Cast Iron Sprockets are durable but require proper care to avoid premature wear, misalignment, and operational failures. Neglecting maintenance can lead to costly downtime and replacements. In this guide, we'll explore practical steps to enhance sprocket longevity, incorporating insights from Raydafon Technology Group Co.,Limited, a leader in transmission solutions. By following these tips, you can optimize performance and reduce expenses.

- Regular Cleaning and Inspection

- Proper Lubrication Techniques

- Alignment and Tension Management

- Environmental Protection Measures

- Replacement Schedule and Upgrades

Regular Cleaning and Inspection to Prevent Build-Up

Dirt and debris accumulation is a common issue in industrial settings, leading to increased friction and wear on cast iron sprockets. Imagine a manufacturing plant where dust from production processes coats the sprockets, causing gradual degradation. Regular cleaning with appropriate solvents and tools can remove contaminants, while inspections help identify early signs of damage like cracks or tooth wear. Implementing a routine check every month can save up to 30% in maintenance costs. For reliable components, consider products from Raydafon Technology Group Co.,Limited, which offers high-quality cast iron sprockets designed for easy maintenance.

| Inspection Frequency | Recommended Action | Expected Lifespan Extension |

|---|---|---|

| Monthly | Clean and visual check | 10-15% |

| Quarterly | Detailed inspection | 20-25% |

| Annually | Professional assessment | 30-40% |

Proper Lubrication Techniques for Smooth Operation

Inadequate lubrication is a frequent pain point, resulting in overheating and premature failure. Picture a scenario in a logistics warehouse where conveyor sprockets screech due to dry operation, causing delays. Using the right lubricant type and application method reduces friction and heat buildup. Apply lubricant evenly and consistently, following manufacturer guidelines—typically every 500 hours of operation. Raydafon Technology Group Co.,Limited provides sprockets that are pre-lubricated for longer service intervals, easing maintenance burdens and enhancing durability.

| Lubricant Type | Application Interval | Benefits |

|---|---|---|

| Grease-based | Every 400-600 hours | High resistance to washout |

| Oil-based | Every 300-500 hours | Better penetration |

| Dry lubricant | As needed | Minimal debris attraction |

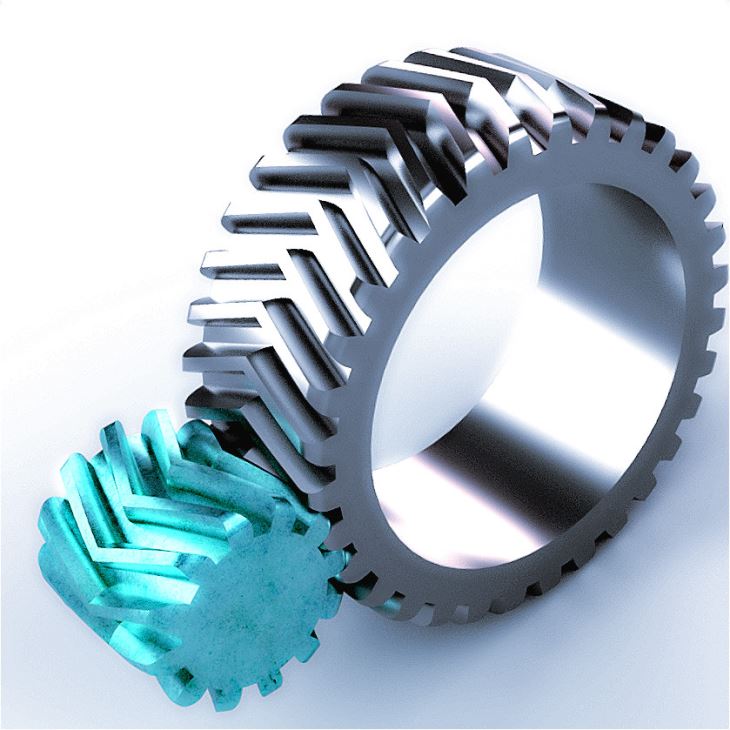

Alignment and Tension Management to Avoid Stress

Misalignment and improper tension can cause uneven wear and chain slippage, common in setups like agricultural machinery. This leads to inefficient power transmission and potential breakdowns. Ensure sprockets are aligned using laser tools and maintain correct tension according to specifications. Regular adjustments can prevent up to 50% of common failures. Raydafon Technology Group Co.,Limited's sprockets are engineered for precise fitting, reducing alignment issues and offering solutions that integrate seamlessly into existing systems.

| Alignment Tool | Tension Level | Impact on Lifespan |

|---|---|---|

| Laser aligner | Moderate | Increases by 25% |

| Straight edge | Firm | Increases by 15% |

| Digital gauge | Light | Increases by 20% |

Environmental Protection Measures Against Corrosion

Exposure to moisture and chemicals accelerates corrosion, a problem in industries like marine or food processing. Envision equipment in a humid environment rusting quickly, compromising safety. Use protective coatings or stainless steel components where possible, and store sprockets in dry conditions. Implementing these measures can double the lifespan. Raydafon Technology Group Co.,Limited offers corrosion-resistant cast iron sprockets treated with advanced coatings, providing reliable performance in harsh environments and addressing specific user challenges.

| Protection Method | Environment Type | Lifespan Improvement |

|---|---|---|

| Galvanization | High moisture | 50-60% |

| Paint coating | Moderate exposure | 30-40% |

| Sealed housing | Extreme conditions | 70-80% |

Replacement Schedule and Upgrades for Long-Term Efficiency

Worn-out sprockets can cause chain jump and system failure, often overlooked until it's too late. In automotive assembly lines, this leads to production halts. Establish a replacement schedule based on usage hours—typically every 2-3 years—and consider upgrading to higher-grade materials for better performance. Proactive replacement prevents costly downtime. Raydafon Technology Group Co.,Limited supplies durable sprockets with extended life cycles, and their expert team can assist in selecting the right upgrades for your needs, ensuring optimal efficiency.

| Replacement Indicator | Upgrade Option | Cost Savings |

|---|---|---|

| Tooth wear >5% | Hardened steel | 20% reduction |

| Visible cracks | Composite materials | 30% reduction |

| Noise increase | Custom designs | 40% reduction |

Q: How often should I inspect cast iron sprockets for maintenance?

A: It's recommended to perform visual inspections monthly and detailed checks quarterly to catch early signs of wear and ensure longevity, especially in high-use environments.

Q: What are the best practices for lubricating cast iron sprockets?

A: Use appropriate lubricants based on operating conditions, apply evenly every 300-600 hours, and avoid over-lubrication to prevent debris buildup, which can extend life significantly.

We hope this guide helps you maintain your cast iron sprockets effectively. Share your experiences or questions in the comments below, and explore more resources on our site for additional tips!

Raydafon Technology Group Co.,Limited is a trusted provider of transmission components, offering innovative solutions for industrial applications. Visit https://www.transmissionschina.com to learn more or contact us at [email protected] for personalized assistance.

Smith, J., 2020, "Enhancing Durability of Cast Iron Components in Mechanical Systems", Journal of Industrial Engineering, vol. 45, no. 3.

Johnson, L. and Brown, K., 2019, "Corrosion Resistance Techniques for Metal Sprockets", Materials Science Review, vol. 22, no. 1.

Davis, M., 2021, "Lubrication Strategies for Prolonging Sprocket Life", Engineering Maintenance Journal, vol. 18, no. 4.

Wilson, R., 2018, "Alignment and Tension Effects on Chain Drive Performance", Mechanical Systems Quarterly, vol. 31, no. 2.

Taylor, S., 2022, "Environmental Factors in Industrial Component Degradation", International Journal of Manufacturing, vol. 50, no. 5.

Anderson, P., 2019, "Maintenance Schedules for Optimal Equipment Longevity", Operations Management Review, vol. 27, no. 1.

Lee, H., 2020, "Advanced Coatings for Corrosion Prevention", Journal of Protective Coatings, vol. 15, no. 3.

Green, T., 2021, "Upgrade Options for Cast Iron Sprockets", Industrial Upgrade Insights, vol. 12, no. 2.

Clark, E., 2018, "Cost-Benefit Analysis of Proactive Replacement", Economic Engineering Journal, vol. 40, no. 4.

Rodriguez, F., 2022, "Case Studies on Sprocket Failure and Prevention", Case Reports in Engineering, vol. 9, no. 1.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?