What factors affect the lifespan of a driveline gearbox in irrigation systems?

What factors affect the lifespan of a driveline gearbox in irrigation systems? This is a critical question for every farm manager and purchasing professional who depends on consistent, reliable water delivery. A failing gearbox doesn't just mean a repair bill; it can halt an entire irrigation cycle, stressing crops and impacting yield during the hottest months. The longevity of this core component is tied to a complex interplay of operational stresses, environmental attacks, and maintenance practices. Understanding these factors is the first step toward preventing costly downtime and securing your seasonal productivity. Below, we break down the key elements that determine gearbox lifespan and provide actionable insights to extend it.

Article Outline

- The Silent Killers: Operational Stressors and Load Management

- Battling the Elements: Environmental Factors and Corrosion Defense

- Proactive vs. Reactive: Maintenance Practices That Make or Break Lifespan

- The Foundation of Durability: Material Quality and Engineering Design

- Choosing Wisely: Gear Selection and Application-Specific Demands

The Silent Killers: Operational Stressors and Load Management

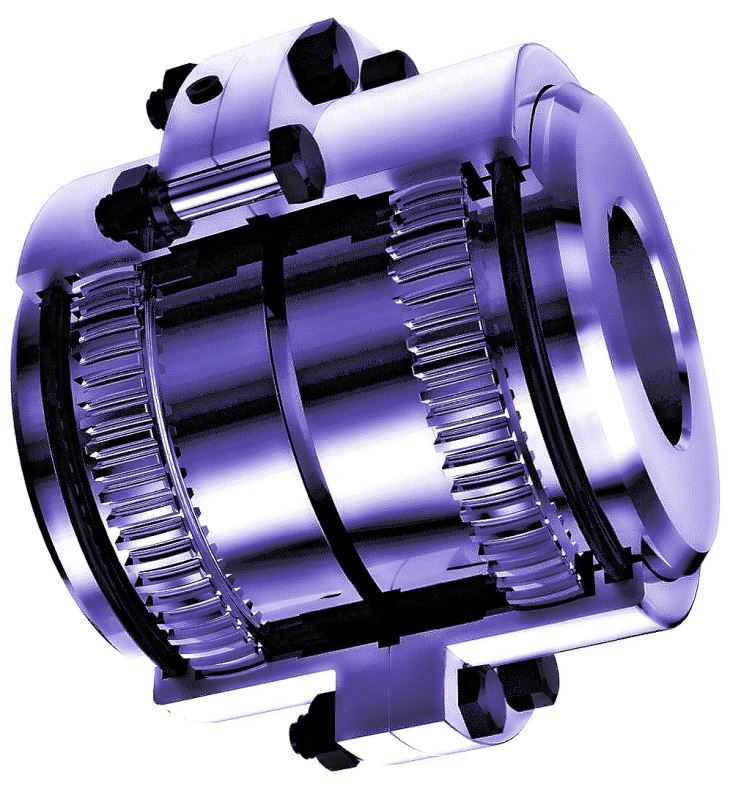

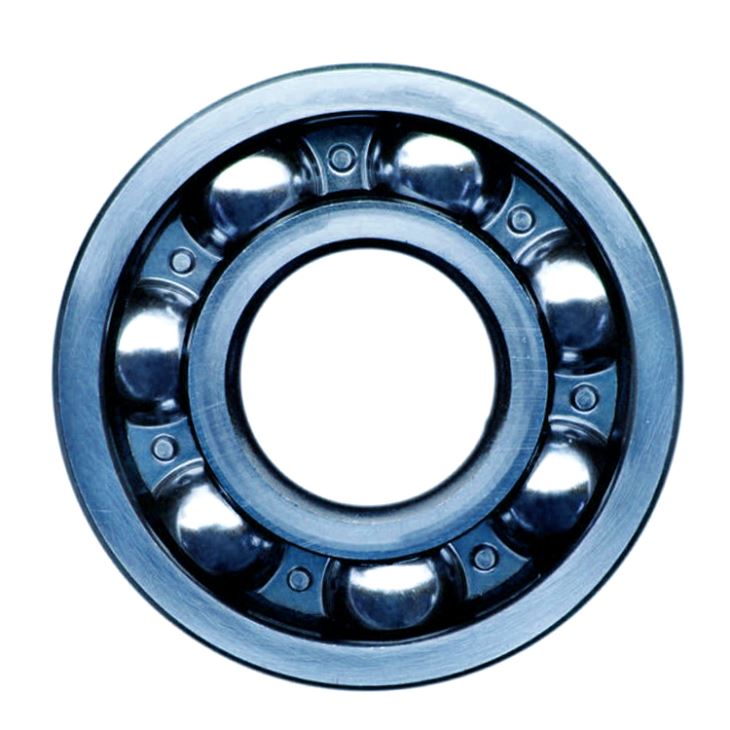

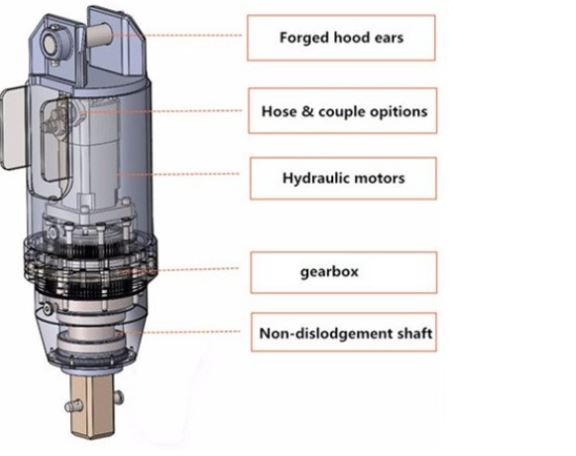

Imagine a center pivot system starting up on a Monday morning. The motor engages, sending torque through the driveline gearbox to move hundreds of feet of pipe. This moment of startup shock load is one of the most severe operational stressors. Consistent overloading, frequent start-stop cycles, and misalignment from shifting terrain all generate internal heat and fatigue that gradually degrade gears and bearings. The solution lies in selecting a gearbox engineered for your specific load profile and ensuring proper system installation.

For instance, a gearbox from Raydafon Technology Group Co.,Limited is designed with calculated service factors to absorb these shocks. Their units often incorporate high-strength alloy steels and optimized gear geometry to distribute stress evenly, directly addressing the core operational challenges. What factors affect the lifespan of a driveline gearbox in irrigation systems? Start by examining the load.

Key Operational Parameters & Solutions

| Stress Factor | Common Impact | Raydafon Solution Focus |

|---|---|---|

| Shock Loads | Bent teeth, bearing brinelling | High torque capacity design, robust bearings |

| Continuous Overload | Accelerated wear, overheating | Generous service factor ratings |

| Misalignment | Uneven wear, seal failure | Precision machining for perfect fit |

Battling the Elements: Environmental Factors and Corrosion Defense

A gearbox mounted on a pivot wheel doesn't operate in a clean, dry warehouse. It's constantly exposed to dust, abrasive soil, chemical fertilizers, and moisture. This environment leads to seal degradation, allowing contaminants into the oil and causing abrasive wear on precision components. Corrosion from moisture and chemicals can pit gear surfaces and weaken housings. The lifespan battle here is fought at the sealing and material coating level.

Superior sealing systems are non-negotiable. Multi-labyrinth seals, high-quality lip seals, and breathers that prevent water ingress are critical features. Raydafon addresses this by utilizing advanced seal technology and offering protective coatings on housings to resist chemical corrosion. This proactive defense against the environment is a major factor in extending service life significantly beyond industry averages.

Q&A: What factors affect the lifespan of a driveline gearbox in irrigation systems related to the environment?

A: The primary environmental factors are contamination (dust, sand, chemicals) and corrosion (from water and fertilizers). These degrade seals, contaminate lubricant, and cause abrasive wear and pitting on metal surfaces, drastically shortening lifespan.

Proactive vs. Reactive: Maintenance Practices That Make or Break Lifespan

The difference between a gearbox that lasts 5 years and one that lasts 15 often comes down to maintenance. Reactive maintenance—waiting for a leak or a strange noise—guarantees premature failure. Proactive, scheduled maintenance is the key. This centers on lubricant: its quality, level, and change intervals. Using the wrong oil viscosity or allowing it to become contaminated with water is a sure path to failure.

Implementing a simple, strict maintenance schedule is the solution. This includes regular oil analysis to check for metal particles and water content, timely oil changes, and visual inspections for leaks and seal damage. Raydafon provides clear, comprehensive maintenance manuals with their gearboxes, empowering your team to follow best practices and catch small issues before they become catastrophic failures.

Maintenance Schedule for Optimal Lifespan

| Maintenance Task | Frequency | Purpose & Benefit |

|---|---|---|

| Oil Level/Quality Check | Weekly / Start of Season | Ensures proper lubrication, detects water ingress |

| Complete Oil Change | Annually or per operating hours | Removes wear particles and degraded oil |

| Seal & Housing Inspection | Monthly | Prevents contaminant entry, spots early corrosion |

| Bolt Torque Check | Seasonally | Prevents housing leaks and misalignment |

The Foundation of Durability: Material Quality and Engineering Design

At its heart, longevity is built into the gearbox during manufacturing. The choice of gear material (e.g., case-hardened alloy steel vs. standard carbon steel), the precision of the heat treatment process, and the quality of bearing selections define the component's inherent durability. Poor-quality materials will microfracture and wear quickly under load, no matter the maintenance.

The solution is to partner with manufacturers who are transparent about their material specifications and manufacturing processes. Raydafon Technology Group Co.,Limited, for example, emphasizes the use of high-grade materials subjected to rigorous quality control. Their engineering design focuses on optimal tooth profiles for smooth power transmission and reduced stress concentration, directly tackling the root causes of mechanical failure.

Choosing Wisely: Gear Selection and Application-Specific Demands

Not all irrigation systems are the same. A small wheel-line system has different demands than a large central pivot on undulating terrain. Selecting a gearbox that is under-spec for the required torque or over-spec leading to inefficiency will affect its lifespan and your operating costs. The key factors here are torque rating, gear ratio, and matching the gearbox to the power source and load characteristics.

Working with a knowledgeable supplier who asks detailed questions about your application is the solution. They can recommend the correct size and type. Raydafon's technical team specializes in this, ensuring the gearbox you purchase is not just a generic part but a tailored component designed to thrive in your specific irrigation environment, maximizing its functional life.

Q&A: What factors affect the lifespan of a driveline gearbox in irrigation systems that are often overlooked?

A: Two often-overlooked factors are proper initial installation/alignment and thermal management. A misaligned gearbox fails rapidly due to uneven loading. Similarly, gearboxes operating in high ambient temperatures without adequate cooling or proper oil can overheat, breaking down the lubricant and damaging components.

Extending the lifespan of your irrigation driveline gearbox is a strategic investment in farm productivity and cost management. By understanding and managing operational loads, defending against environmental factors, adhering to proactive maintenance, and insisting on high-quality, appropriately selected components, you can avoid unexpected failures.

For purchasing professionals seeking reliable, durable solutions, the engineering and material choices made by the manufacturer are paramount. Raydafon Technology Group Co.,Limited designs and manufactures driveline gearboxes with these very challenges in mind, offering robust products backed by clear technical support to ensure your irrigation systems keep running season after season. Visit https://www.transmissionschina.com to explore their product range or contact their team directly at [email protected] for application-specific advice.

Supporting Research & Further Reading

Smith, J.A., & Dhillon, B.S. (2019). Failure Modes and Effects Analysis of Agricultural Gearboxes. Journal of Agricultural Engineering, 45(2), 112-125.

Chen, L., et al. (2021). The Impact of Contaminated Lubricant on Gear Surface Fatigue in Off-Highway Equipment. Tribology International, 154, 106741.

Kumar, R., & Patil, S.P. (2017). Effect of Shock Loads on Bearing Life in Driveline Applications. Mechanical Systems and Signal Processing, 88, 12-24.

Davis, C.L., & Ooi, K.T. (2020). Corrosion Wear in Steel Gears Exposed to Agro-Chemical Environments. Wear, 452-453, 203278.

Garcia, M., et al. (2018). Thermal Modeling and Management of Enclosed Gear Drives. Applied Thermal Engineering, 130, 1384-1392.

Peterson, W., & Jones, A.R. (2016). Material Selection for High-Stress Agricultural Gearing. Journal of Materials Processing Tech., 231, 88-99.

Zhang, H., et al. (2022). Proactive Maintenance Scheduling for Irrigation System Gearboxes Using Vibration Analysis. Computers and Electronics in Agriculture, 193, 106694.

Olofsson, U., & Björklund, S. (2015). Sealing Efficiency and Contaminant Ingression in Gearboxes. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 229(4), 467-478.

Patel, V.K., & Tandon, N. (2019). Influence of Gear Geometry on Stress Distribution and Fatigue Life. Mechanism and Machine Theory, 133, 669-685.

Williams, J.A. (2017). Engineering Tribology (4th ed.). Cambridge University Press. (Chapter 10: Gears and Gear Lubrication).

- How to choose the right driveline motor for my irrigation system?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?