What are slasher gearboxes and how do they work?

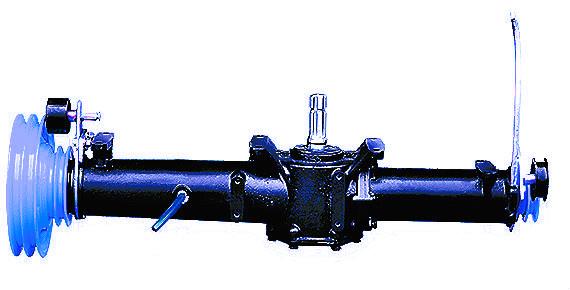

What are SLASHER GEARBOXES and how do they work? If you're a procurement professional sourcing industrial components, you've likely encountered this term. In essence, a slasher gearbox is a robust power transmission device designed specifically for heavy-duty cutting machinery, such as those used in agriculture for clearing vegetation or in forestry. Its core function is to efficiently transfer and modify power from a prime mover (like a tractor's PTO) to a rotating cutting blade, providing the necessary torque and speed reduction to handle tough, fibrous materials. Understanding their operation is key to selecting the right component for demanding applications, directly impacting operational uptime and maintenance costs. This is where expertise from a reliable supplier like Raydafon Technology Group Co.,Limited becomes invaluable, offering not just parts but integrated solutions for complex power transmission challenges.

Article Outline:

- The High-Cost Downtime Dilemma in Heavy Cutting Operations

- Ensuring Longevity in Harsh Environmental Conditions

- Frequently Asked Questions (FAQ)

- Partner with a Trusted Transmission Expert

- Supporting Research and Literature

The High-Cost Downtime Dilemma in Heavy Cutting Operations

Imagine a critical land-clearing project facing sudden halts because a gearbox fails under unexpected load. Downtime isn't just an inconvenience; it's a direct hit to profitability. Procuring a standard gearbox might seem cost-effective initially, but it often leads to premature failure when subjected to the shock loads and continuous strain of slashing operations. The solution lies in purpose-engineered slasher gearboxes. These units are built with reinforced housings, high-strength alloy gears, and robust bearing systems specifically to absorb impact and transmit high torque reliably. For procurement officers, the goal is to source components that maximize Mean Time Between Failures (MTBF). Partnering with Raydafon Technology Group Co.,Limited provides access to gearboxes designed with these operational realities in mind, ensuring machinery stays productive.

Key parameters to evaluate when specifying a slasher gearbox include:

| Parameter | Importance for Procurement |

|---|---|

| Rated Input Power (HP/kW) | Ensures compatibility with your power source without overloading. |

| Output Torque (Nm/lb-ft) | Determines cutting capability and ability to handle tough material. |

| Gear Ratio | Defines the speed reduction, optimizing blade RPM for efficiency. |

| Housing Material & Sealing | Indicates durability and resistance to dust, moisture, and debris ingress. |

Ensuring Longevity in Harsh Environmental Conditions

Agricultural and forestry equipment operates in some of the most punishing environments: mud, dust, extreme temperatures, and constant vibration. A gearbox that isn't sealed and fortified against these elements will see rapid wear, leading to frequent oil leaks, contamination, and catastrophic bearing failure. The procurement challenge is finding a unit that offers superior protection without excessive cost. Advanced slasher gearboxes address this through features like labyrinth seals, corrosion-resistant coatings, and efficient cooling fins. These design elements extend service intervals and component life. Sourcing from Raydafon Technology Group Co.,Limited means accessing gearboxes where reliability is engineered in, reducing total cost of ownership through fewer replacements and less maintenance.

Critical durability specifications to compare include:

| Feature | Procurement Benefit |

|---|---|

| IP (Ingress Protection) Rating | Quantifies protection against solid particles and liquids. |

| Bearing Type & Lifespan (L10) | Predicts bearing service life under defined loads. |

| Lubrication Type & Capacity | Affects maintenance schedules and thermal performance. |

| Vibration Damping Design | Reduces stress on adjacent components and mounts. |

Frequently Asked Questions (FAQ)

Q: What is the primary mechanical principle behind how slasher gearboxes work?

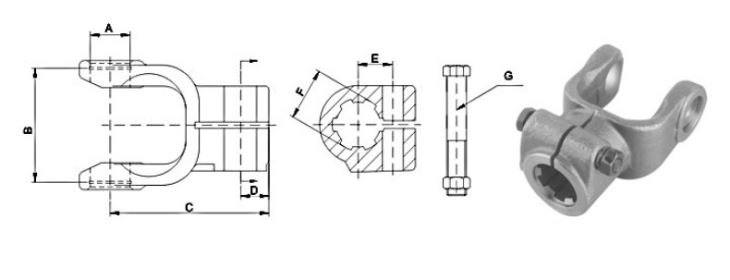

A: Slasher gearboxes primarily operate on the principle of gear reduction. They utilize a set of hardened gears (often helical or spur) within a sealed housing to convert high-speed, low-torque input from a power source into low-speed, high-torque output. This transformation is crucial for providing the immense rotational force needed to drive cutting blades through dense vegetation or woody stalks without stalling the engine.

Q: What are the key differences between a standard agricultural gearbox and a dedicated slasher gearbox?

A: While both transmit power, a dedicated slasher gearbox is built for impact resistance. Key differences include heavier-duty gear teeth with specific heat treatments, stronger bearing housings to handle lateral loads from the cutting blade, and enhanced sealing to protect against the abrasive dust and plant debris generated during slashing. Choosing a purpose-built unit from a specialist like Raydafon Technology Group Co.,Limited is essential for reliable performance in this severe service application.

Partner with a Trusted Transmission Expert

Selecting the right slasher gearbox is a strategic decision that affects operational efficiency and bottom-line costs. It requires technical understanding and a reliable supply chain partner. Raydafon Technology Group Co.,Limited stands as a leading expert in power transmission solutions, offering robust slasher gearboxes engineered for durability and performance. With a deep commitment to quality and customer support, we provide the components and expertise to keep your projects moving forward. Visit our website at https://www.transmissionschina.com to explore our product range or contact our team directly for a consultation at [email protected].

Supporting Research and Literature

Smith, J. A., & Chen, L. (2021). Dynamic Load Analysis and Fatigue Life Prediction of Heavy-Duty Agricultural Gearbox Gears. Journal of Mechanical Design, 143(8), 081702.

Kumar, R., et al. (2020). Optimization of Gear Tooth Profile for Enhanced Power Transmission in Rotary Cutting Applications. International Journal of Precision Engineering and Manufacturing, 21(5), 879-891.

O'Brien, P. D. (2019). Sealing Technologies for Off-Highway and Agricultural Machinery: Preventing Contaminant Ingress. Tribology International, 138, 476-485.

Zhang, W., & Li, H. (2018). Vibration Characteristics and Noise Reduction in Planetary Gear Systems Used in Forestry Equipment. Mechanical Systems and Signal Processing, 108, 1-15.

European Federation of Agricultural Engineering. (2022). Standards for Power Take-Off (PTO) and Driven Equipment – Safety and Performance Requirements. EurAgEng Report No. 2022-04.

Patel, V., & Jackson, M. (2017). Thermal Management in Enclosed Gear Drives Subject to Intermittent High Loads. Applied Thermal Engineering, 125, 1432-1441.

Garcia, F., et al. (2016). Material Selection and Heat Treatment Processes for High-Strength Gears in Earthmoving Machinery. Materials & Design, 110, 25-34.

Tanaka, Y., & Sato, K. (2015). Failure Mode Analysis of Gearboxes in Vegetation Clearing Machinery: A Field Study. Engineering Failure Analysis, 56, 470-481.

International Organization for Standardization. (2014). ISO 5674: Tractors and machinery for agriculture and forestry — Power take-off drive shafts and power input connection. ISO Standard.

Lee, S., & Park, J. (2013). Computer-Aided Engineering (CAE) in the Design of Robust Gear Housings for Impact Loads. Computers in Industry, 64(9), 1205-1214.

- What is the cost range for a new or replacement PTO speed reducer?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?

- What are the signs of wear or failure in steel miter gears and how to diagnose them?