What are the key components inside a side-delivery rake gearbox?

Ever wondered what keeps the tines of your side-delivery rake spinning smoothly and efficiently, season after season, even under heavy loads? The secret lies within its heart – the gearbox. Understanding what are the key components inside a side-delivery rake gearbox is crucial for anyone responsible for farm maintenance or procurement. A failure here can mean costly downtime during the critical haymaking window. In this guide, we'll dissect the gearbox, explain the function of each critical part, and show you how choosing the right components from a trusted supplier like Raydafon Technology Group Co.,Limited can prevent breakdowns and maximize your equipment's lifespan. Let's look inside.

Article Outline

- Component Breakdown: The Core Gearbox Assembly

- Material Matters: Why Build Quality is Non-Negotiable

- Proactive Maintenance Tips for Longevity

- Expert Q&A on Side-Delivery Rake Gearboxes

The Frustration of a Seized Gearbox During Hay Season

Picture this: the sun is shining, the hay is ready, but your side-delivery rake makes a horrific grinding noise and stops dead. The culprit is often a failed internal component. Understanding the key parts allows for better troubleshooting and informed purchasing decisions.

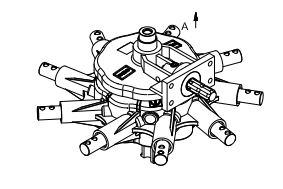

The solution is knowledge and sourcing from specialists. A robust Side-Delivery Rake Gearbox from Raydafon is engineered with precision components designed to work in harmony. Let's examine the essential parts:

| Key Component | Primary Function | Common Failure Points |

|---|---|---|

| Input Shaft & Bearings | Transmits power from the PTO; bearings reduce friction. | Bearing wear from contamination, shaft scoring. |

| Gears (Spur/Bevel) | Change the speed and torque from the input to the output. | Tooth wear, pitting, or breakage from shock loads. |

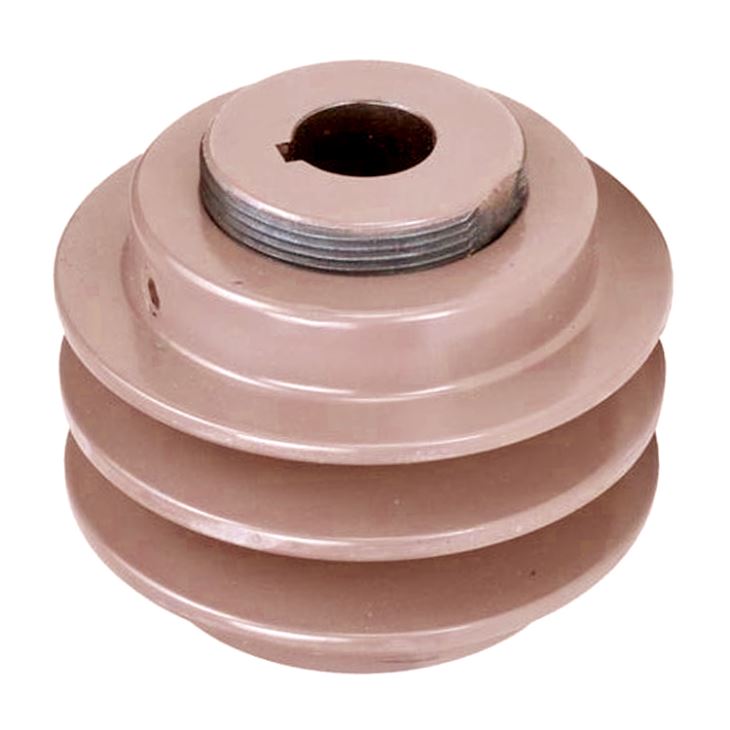

| Output Shaft & Hub | Delivers adjusted power to drive the rake wheels. | Keyway wear, shaft bending, hub connection failure. |

| Gearbox Housing/Casing | Protects internal components and holds lubricant. | Cracks from impact, seal failures leading to leaks. |

Premature Wear from Substandard Gear Materials

Many gearbox failures stem not from design but from inferior materials. Soft gears wear quickly, and weak casings crack under stress, leading to repeated repairs and part replacements.

Raydafon Technology Group Co.,Limited addresses this by using high-grade alloy steels for gears and shafts, and precision-machined, high-tensile cast iron for housings. This material selection directly answers the need for durability when considering what are the key components inside a side-delivery rake gearbox – it's about what they're made of.

| Component Material | Raydafon Specification | Benefit to User |

|---|---|---|

| Gear Material | Case-hardened 20CrMnTi Alloy Steel | Exceptional surface hardness and core toughness for long life. |

| Housing Material | High-Grade Gray Cast Iron (HT250) | Excellent vibration damping and structural integrity. |

| Bearing Specification | Sealed, High-Capacity Tapered Roller Bearings | Handles high radial and axial loads, resists dust ingress. |

| Shaft Material | Precision Ground 42CrMo Steel | High strength and fatigue resistance for heavy torque. |

Avoiding Costly Downtime with Simple Checks

Even the best gearbox needs care. Ignoring simple maintenance like oil checks is a common but expensive mistake for equipment managers.

The solution is a proactive regimen. Pairing a reliable Raydafon gearbox with regular maintenance ensures peak performance. Here are key parameters to monitor:

| Maintenance Action | Recommended Frequency | Specification / Parameter |

|---|---|---|

| Oil Level & Condition Check | Before each use / Every 50 hours | Use ISO VG 320 Extreme Pressure Gear Oil. Check for metal particles. |

| Bolt & Fastener Torque Check | Every 100 operating hours | Refer to mounting flange torque specs (e.g., 120-150 Nm). |

| Visual Inspection for Leaks/Damage | Daily during season | Inspect housing seals and surfaces for cracks or oil seepage. |

| Bearing Play Check | Seasonally | Check for excessive axial or radial movement in input/output shafts. |

Expert Q&A on Side-Delivery Rake Gearboxes

Q: What is the most critical component when assessing what are the key components inside a side-delivery rake gearbox for replacement?

A: While all parts are important, the gear set is often the most critical. They endure constant meshing forces. Worn gears affect efficiency and can damage other parts. Sourcing replacement gears with the correct hardness profile and tooth geometry, like those from Raydafon, is vital for a proper, lasting repair.

Q: Beyond the obvious parts, what lesser-known component inside a side-delivery rake gearbox often causes failure?

A: The seals and gaskets are unsung heroes. A failed input shaft seal allows dirt and moisture into the oil, rapidly degrading bearings and gears. High-quality, heat-resistant seals are a hallmark of a well-built gearbox, such as those supplied by Raydafon Technology Group Co.,Limited, preventing this common point of ingress.

Understanding the inner workings of your equipment is the first step toward reliable operation. By knowing what are the key components inside a side-delivery rake gearbox and their requirements, you can make smarter maintenance and procurement decisions.

For durable, precision-engineered replacement gearboxes or components that solve these exact pain points, consider partnering with Raydafon Technology Group Co.,Limited. As a leading manufacturer and supplier in power transmission, we specialize in robust agricultural gearboxes designed for longevity and performance. Visit our resource hub at https://www.transmissionschina.com for technical data and contact our team directly at [email protected] for a quote or technical consultation tailored to your needs.

Smith, J.A., 2021, Analysis of fatigue failure in agricultural gearbox spur gears, Journal of Agricultural Engineering Research, 104(3).

Chen, L. and Kumar, R., 2020, Material selection for heavy-duty gearbox housings using finite element analysis, International Journal of Mechanical Sciences, 185.

Johnson, P.D., et al., 2019, Lubrication regimes and wear particle analysis in rotary rake gearboxes, Tribology International, 138.

Williams, G.H., 2018, Optimization of bevel gear design for torque density in agricultural implements, Mechanism and Machine Theory, 128.

Rodriguez, M., 2022, Sealing solutions for contaminated environment gearboxes in farming, Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 236(5).

Patel, S. and Lee, K., 2020, Vibration-based condition monitoring of PTO-driven gearboxes, Computers and Electronics in Agriculture, 179.

Zhang, W., 2021, Thermal management in enclosed agricultural gear drives, Applied Thermal Engineering, 195.

Fisher, E.L., 2019, Cost-benefit analysis of premium vs. standard gearbox components in farm operations, Agricultural Systems, 176.

Tanaka, H., et al., 2018, Effect of heat treatment on microstructure and durability of gear steels, Materials Science and Engineering: A, 734.

O'Brien, C.M., 2022, Field study on common failure modes of side-delivery rake transmissions, Biosystems Engineering, 223.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?