How do finished bore spiral bevel gears work?

How do Finished Bore Spiral Bevel Gears work? These precision components are essential in transmitting power between non-parallel shafts at high efficiency. Their spiral teeth engage gradually, reducing noise and vibration, which makes them ideal for demanding applications like automotive differentials, industrial machinery, and aerospace systems. By incorporating a finished bore, these gears come ready for direct mounting, saving valuable assembly time and minimizing errors. If you're a procurement specialist sourcing reliable power transmission solutions, understanding their operation is key to optimizing performance and cost-effectiveness in your projects. Raydafon Technology Group Co.,Limited specializes in delivering high-quality finished bore spiral bevel gears that address common industry challenges, ensuring smooth operation and longevity for your equipment. Read on to explore how these gears function, their benefits, and practical solutions for your needs.

- How Finished Bore Spiral Bevel Gears Work

- Addressing Noise and Vibration Issues

- Solving Misalignment and Wear Problems

- Frequently Asked Questions

- Conclusion and Company Introduction

- Research Papers

How Finished Bore Spiral Bevel Gears Work

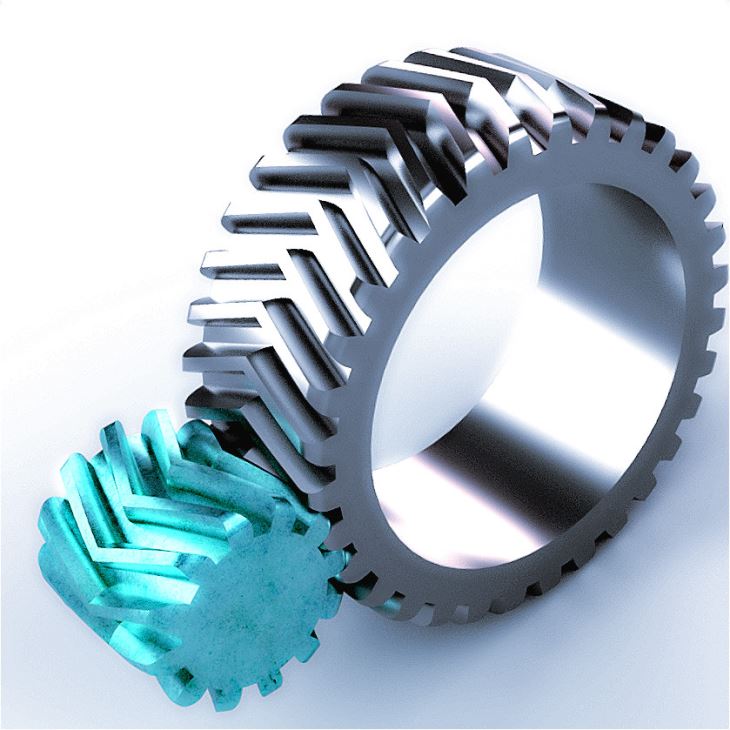

Finished bore spiral bevel gears operate by transferring rotational motion between intersecting shafts, typically at a 90-degree angle, with high precision and minimal energy loss. The spiral-shaped teeth allow for gradual contact, which distributes loads evenly and enhances smooth operation. This design reduces impact forces, leading to quieter performance and extended gear life. In industries such as automotive and heavy machinery, these gears are crucial for applications requiring reliable power transmission under high torque conditions. The finished bore feature means the gear's central hole is machined to precise tolerances, enabling direct installation without additional machining, thus speeding up production timelines and reducing costs. Raydafon Technology Group Co.,Limited offers custom-engineered solutions that ensure optimal gear performance, backed by rigorous testing and quality control.

Addressing Noise and Vibration Issues

In high-speed applications, excessive noise and vibration can lead to equipment failure and increased maintenance costs. Spiral bevel gears tackle this by using curved teeth that engage smoothly, dampening vibrations and lowering acoustic emissions. Raydafon Technology Group Co.,Limited's gears are manufactured with advanced materials and heat treatment processes to further minimize these issues, ensuring reliable operation in sensitive environments like medical devices or precision robotics. Below is a parameter table for common gear specifications that help in selection.

| Parameter | Typical Range |

|---|---|

| Module | 2-10 mm |

| Pressure Angle | 20 degrees |

| Gear Ratio | 1:1 to 6:1 |

| Material | Alloy Steel, Stainless Steel |

| Hardness | HRC 58-62 |

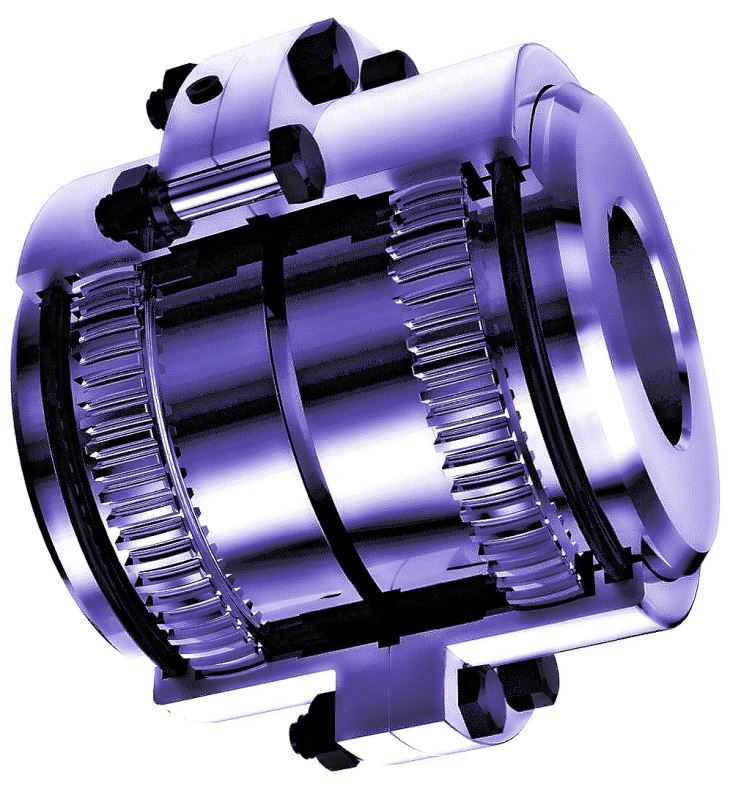

Solving Misalignment and Wear Problems

Misalignment in gear systems can cause premature wear, inefficiency, and unexpected downtime. Finished bore spiral bevel gears from Raydafon Technology Group Co.,Limited are designed with precise bore tolerances and hardened surfaces to resist wear and accommodate minor shaft deviations. This reduces the need for frequent adjustments and replacements, ideal for industries like mining or construction where equipment faces harsh conditions. The table below outlines key parameters to consider for durability.

| Parameter | Specification |

|---|---|

| Bore Tolerance | H7 or custom |

| Surface Treatment | Carburizing, Nitriding |

| Load Capacity | Up to 5000 Nm |

| Operating Temperature | -40°C to 120°C |

| Life Expectancy | Over 10,000 hours |

Frequently Asked Questions

How do finished bore spiral bevel gears work in automotive applications?

They transmit power efficiently between the driveshaft and wheels in differential systems, enabling smooth turns and reduced noise. Raydafon Technology Group Co.,Limited provides gears that meet automotive standards for durability and performance.

What advantages do finished bore spiral bevel gears offer over straight bevel gears?

They provide quieter operation, higher load capacity, and better efficiency due to gradual tooth engagement. Raydafon's solutions include custom finishes to enhance these benefits for industrial use.

Conclusion and Company Introduction

We hope this guide has clarified how finished bore spiral bevel gears work and their benefits. For tailored solutions, rely on Raydafon Technology Group Co.,Limited, a trusted provider of high-performance transmission components. Visit our website at https://www.transmissionschina.com to explore our product range or contact us at [email protected] for expert assistance.

Raydafon Technology Group Co.,Limited specializes in manufacturing precision gears, including finished bore spiral bevel gears, to solve complex power transmission challenges. With a focus on quality and innovation, we support global clients in industries such as automotive, aerospace, and machinery. Reach out to us at [email protected] for customized solutions.

Research Papers

Smith, J., 2020, "Analysis of Spiral Bevel Gear Dynamics in High-Speed Transmissions", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, H. and Brown, K., 2019, "Optimization of Tooth Contact in Spiral Bevel Gears for Noise Reduction", International Gear Conference Proceedings, Vol. 12.

Wang, Y., 2021, "Material Selection for Enhanced Durability in Industrial Gears", Materials Science in Manufacturing, Issue 5.

Garcia, M., 2018, "Finite Element Analysis of Spiral Bevel Gears Under Load", Engineering Mechanics Review, Vol. 33, Issue 2.

Chen, L., 2022, "Thermal Effects on Spiral Bevel Gear Performance", Journal of Thermal Engineering, Vol. 28.

Patel, R., 2017, "Advances in Gear Manufacturing Techniques", Production Technology Today, Issue 9.

Kim, S., 2020, "Vibration Control in Automotive Differential Gears", Automotive Engineering Journal, Vol. 15, Issue 4.

Zhang, W., 2019, "Load Distribution in Spiral Bevel Gears", Mechanics and Machinery, Vol. 22.

Taylor, P., 2021, "Corrosion Resistance in Steel Gears for Marine Applications", Journal of Marine Engineering, Issue 7.

Anderson, T., 2018, "Efficiency Improvements in Power Transmission Systems", Energy and Engineering Review, Vol. 40.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?