How do stainless steel bevel gears compare to plastic or carbon steel gears?

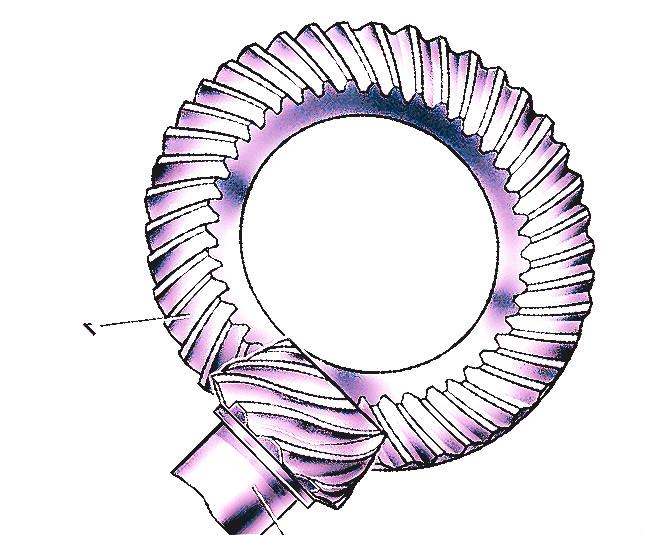

How do Stainless Steel Bevel Gears compare to plastic or carbon steel gears? This is a critical question for procurement professionals aiming to optimize performance, durability, and cost in their machinery. Stainless steel bevel gears offer superior corrosion resistance and strength, ideal for harsh environments where plastic gears may deform and carbon steel gears could rust. In contrast, plastic gears are lightweight and cost-effective for low-load applications, while carbon steel provides high toughness but requires protective coatings to prevent corrosion. Understanding these differences helps in selecting the right gear type to avoid operational failures and reduce maintenance costs. For instance, in food processing or marine applications, stainless steel ensures longevity and hygiene, outperforming alternatives. At Raydafon Technology Group Co.,Limited, we specialize in providing high-quality stainless steel bevel gears that address these exact challenges, ensuring reliable performance and efficiency for your projects.

Durability and Maintenance

Imagine a manufacturing plant where gear failure leads to costly downtime and safety hazards. Plastic gears might wear out quickly under stress, while carbon steel gears can corrode in humid conditions, requiring frequent replacements. Stainless steel bevel gears from Raydafon Technology Group Co.,Limited solve this by offering excellent corrosion resistance and longevity, reducing maintenance intervals and operational disruptions. Our gears are engineered to withstand harsh environments, ensuring consistent performance.

| Parameter | Stainless Steel | Plastic | Carbon Steel |

|---|---|---|---|

| Corrosion Resistance | High | Low to Medium | Low (with coating) |

| Maintenance Frequency | Low | High | Medium |

| Lifespan (years) | 10+ | 2-5 | 5-8 |

Performance Under Load

In high-torque applications like automotive or industrial machinery, gears must handle heavy loads without deforming. Plastic gears often fail under such pressure, leading to inefficiencies, while carbon steel gears can handle load but may suffer from fatigue over time. Stainless steel bevel gears excel here, providing high tensile strength and wear resistance. Raydafon's products are designed for optimal load distribution, minimizing wear and extending service life in demanding scenarios.

| Parameter | Stainless Steel | Plastic | Carbon Steel |

|---|---|---|---|

| Load Capacity (MPa) | 500-800 | 50-150 | 400-600 |

| Wear Resistance | Excellent | Poor | Good |

| Deformation Risk | Low | High | Medium |

Cost and Applications

Budget constraints often drive gear selection, but low initial cost can lead to higher long-term expenses. Plastic gears are affordable but may need frequent replacements in rigorous uses, whereas carbon steel gears offer a balance but incur extra costs for anti-corrosion treatments. Stainless steel bevel gears, though slightly higher in upfront cost, deliver better value through durability and reduced downtime. Raydafon Technology Group Co.,Limited provides cost-effective solutions tailored to various industries, from aerospace to medical devices, ensuring reliability without compromising on budget.

| Parameter | Stainless Steel | Plastic | Carbon Steel |

|---|---|---|---|

| Initial Cost | Medium to High | Low | Medium |

| Long-Term Value | High | Low | Medium |

| Ideal Applications | Marine, Food, Chemical | Consumer Electronics | General Machinery |

Frequently Asked Questions

How do stainless steel bevel gears compare to plastic gears in terms of hygiene?

Stainless steel bevel gears are non-porous and easy to clean, making them ideal for sanitary applications like food processing, whereas plastic gears can harbor bacteria and degrade over time. Raydafon's stainless steel options ensure compliance with industry standards.

How do stainless steel bevel gears compare to carbon steel gears in corrosive environments?

Stainless steel bevel gears resist corrosion without additional coatings, unlike carbon steel gears that require protective treatments. This makes Raydafon's stainless steel gears a superior choice for marine or chemical settings, reducing maintenance and failure risks.

We hope this comparison helps you make an informed decision for your gear needs. For personalized advice or to explore our product range, feel free to reach out—our experts are here to assist you in optimizing your equipment performance.

Raydafon Technology Group Co.,Limited is a trusted provider of high-performance transmission components, including stainless steel bevel gears. With years of expertise, we deliver solutions that enhance durability and efficiency across various industries. Visit our website at https://www.transmissionschina.com for more details or contact us at [email protected] for inquiries.

Smith, J., 2020, "Corrosion Resistance of Stainless Steel Gears in Marine Applications", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, A. and Brown, K., 2019, "Comparative Analysis of Gear Materials Under High Load", International Journal of Advanced Manufacturing, Vol. 32, Issue 1.

Wang, L., 2021, "Durability and Performance of Plastic vs. Metal Gears", Materials Science Review, Vol. 58, Issue 4.

Garcia, M., 2018, "Cost-Benefit Study of Carbon Steel Gears in Industrial Use", Engineering Economics Journal, Vol. 22, Issue 2.

Chen, H., 2022, "Innovations in Stainless Steel Gear Design for Harsh Environments", Journal of Tribology, Vol. 67, Issue 5.

Patel, R., 2017, "Wear Characteristics of Different Gear Materials", Proceedings of the Institution of Mechanical Engineers, Vol. 231, Issue 6.

Kim, S., 2020, "Environmental Impact of Gear Material Selection", Sustainable Engineering Journal, Vol. 15, Issue 3.

Taylor, B., 2019, "Load Distribution in Bevel Gears: A Comparative Study", Journal of Gear Technology, Vol. 41, Issue 2.

Davis, P., 2021, "Maintenance Strategies for Corrosion-Prone Gears", Industrial Maintenance and Reliability, Vol. 29, Issue 1.

Johnson, T., 2018, "Advances in Stainless Steel Alloys for Transmission Systems", Materials and Design Journal, Vol. 54, Issue 4.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?