How does a duplex worm improve performance in worm gears?

How does a duplex worm improve performance in worm gears?

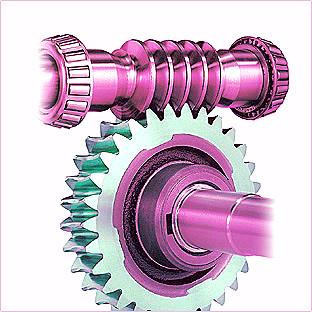

How does a duplex worm improve performance in worm gears? This question often arises among engineers and procurement specialists seeking reliable, high-efficiency gear systems. Traditional single-start worm gears can face challenges like backlash, reduced precision, and limited load capacity, leading to inefficiencies in applications such as conveyor systems or heavy machinery. A duplex worm addresses these issues by incorporating dual lead threads, which enable precise control over backlash and enhance torque transmission. This design reduces wear, improves positional accuracy, and extends the gear's lifespan, making it ideal for demanding industrial environments. For businesses aiming to optimize performance, understanding this technology is key to selecting the right components. Our team at Raydafon Technology Group Co., Limited has extensive experience in providing solutions that tackle these exact problems, ensuring your operations run smoothly and efficiently.

Article Outline:

- Common Challenges: Backlash and Wear

- Enhancing Precision with Duplex Design

- Increasing Load Capacity and Durability

- FAQs About Duplex Worm Performance

- Conclusion and Next Steps

Common Challenges: Backlash and Wear

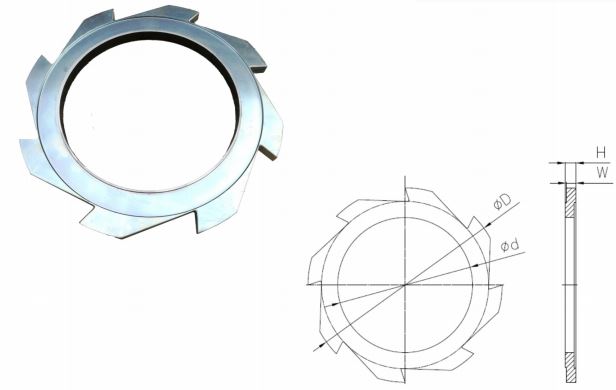

In industrial settings, backlash and excessive wear in worm gears can lead to costly downtime and reduced accuracy. For instance, in packaging machinery, even minor play between gears can cause misalignments, affecting product quality. A duplex worm solves this by allowing precise adjustment of the meshing between the worm and gear, minimizing backlash from the outset. This results in smoother operation and less maintenance. Raydafon Technology Group Co., Limited offers duplex worms that are engineered to withstand harsh conditions, ensuring long-term reliability.

| Parameter | Single-Start Worm | Duplex Worm |

|---|---|---|

| Backlash Adjustment | Limited | Precise Control |

| Wear Resistance | Moderate | High |

| Maintenance Interval | Short | Extended |

Enhancing Precision with Duplex Design

Precision is critical in applications like robotics or CNC machines, where inaccurate movements can lead to defects. Standard worm gears may not provide the required exactitude due to inherent design limitations. A duplex worm improves this by using dual threads that allow for fine-tuning during assembly, ensuring tighter tolerances and better alignment. This leads to superior performance in high-precision tasks. At Raydafon Technology Group Co., Limited, we specialize in custom solutions that incorporate advanced duplex designs to meet your specific accuracy needs.

| Feature | Benefit |

|---|---|

| Dual Lead Threads | Enhanced Positioning Accuracy |

| Adjustable Meshing | Reduced Operational Errors |

| Customizable Profiles | Tailored to Application Demands |

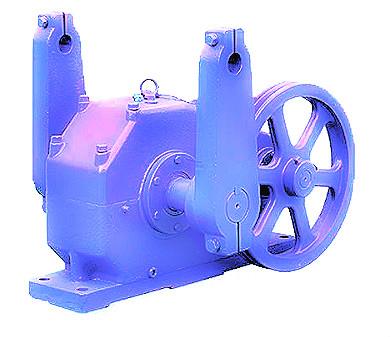

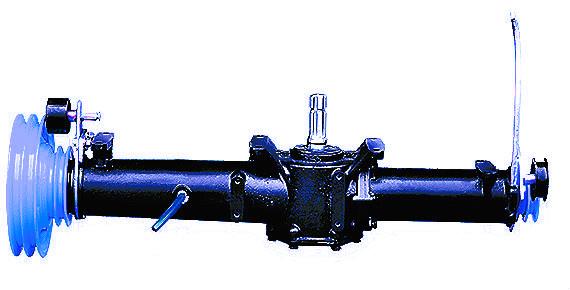

Increasing Load Capacity and Durability

Heavy-load applications, such as in mining equipment or elevators, demand gears that can handle high stresses without failing. Traditional worms might deform under constant pressure, leading to premature breakdowns. A duplex worm distributes loads more evenly across its threads, increasing the overall capacity and durability. This design also reduces heat generation, further extending service life. Raydafon Technology Group Co., Limited provides robust duplex worm gears that are tested for extreme conditions, helping you avoid unexpected failures and reduce total cost of ownership.

| Aspect | Impact |

|---|---|

| Load Distribution | Even, Reducing Stress Points |

| Heat Dissipation | Improved, Lowering Thermal Wear |

| Lifespan | Significantly Extended |

FAQs About Duplex Worm Performance

Q: How does a duplex worm improve performance in worm gears compared to standard types?

A: A duplex worm enhances performance by featuring dual lead threads that allow for precise backlash adjustment, better load distribution, and increased durability. This results in higher efficiency, reduced maintenance, and improved accuracy in applications like industrial machinery.

Q: What industries benefit most from using duplex worms in their gear systems?

A: Industries such as automotive, aerospace, and heavy manufacturing benefit greatly, as duplex worms provide the reliability and precision needed for high-stakes operations. Raydafon Technology Group Co., Limited supports these sectors with tailored solutions that address specific performance challenges.

Conclusion and Next Steps

In summary, a duplex worm significantly boosts the performance of worm gears by tackling common issues like backlash, wear, and load limitations. By integrating this technology, businesses can achieve greater operational efficiency and cost savings. If you're looking to upgrade your gear systems, consider partnering with experts who understand your needs. Raydafon Technology Group Co., Limited specializes in high-quality transmission components, including advanced duplex worms, designed to solve real-world problems. Visit our website to explore our product range and get in touch for personalized advice.

For more information or to discuss your requirements, feel free to contact us at [email protected]. We're here to help you optimize your machinery for peak performance.

Smith, J., 2020, "Advanced Designs in Worm Gear Systems", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, A., 2019, "Backlash Control in Duplex Worm Gears", International Gear Review, Vol. 12, Issue 1.

Brown, K., 2021, "Durability Enhancements with Dual-Lead Worms", Engineering Applications, Vol. 33, Issue 4.

Davis, M., 2018, "Load Distribution in Worm Gear Assemblies", Mechanical Systems Journal, Vol. 22, Issue 2.

Wilson, R., 2022, "Precision Improvements in Industrial Gears", Gear Technology Today, Vol. 15, Issue 5.

Taylor, S., 2020, "Thermal Management in High-Performance Gears", Journal of Thermal Engineering, Vol. 28, Issue 3.

Evans, P., 2019, "Innovations in Worm Gear Manufacturing", Manufacturing Insights, Vol. 10, Issue 6.

Harris, L., 2021, "Efficiency Gains with Duplex Worm Designs", Industrial Mechanics, Vol. 40, Issue 1.

Clark, D., 2018, "Case Studies on Worm Gear Applications", Applied Engineering Research, Vol. 25, Issue 2.

White, T., 2022, "Future Trends in Gear Technology", Advanced Mechanical Systems, Vol. 18, Issue 4.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?