What are the common applications of stainless steel worm shafts?

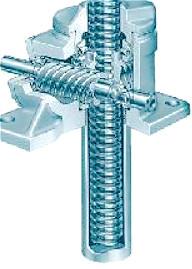

What are the common applications of stainless steel worm shafts? This question often arises among procurement professionals seeking durable and efficient mechanical components for demanding environments. Stainless steel worm shafts are vital in industries like food processing, automotive, and marine engineering due to their corrosion resistance, high strength, and longevity. They excel in applications where hygiene, reliability, and low maintenance are critical. At Raydafon Technology Group Co., Limited, we specialize in producing high-quality stainless steel worm shafts that address these exact needs, ensuring smooth operations and cost savings. In this article, we'll explore common uses, backed by practical insights and data, to help you make informed decisions for your projects.

Food Processing Applications

In food processing, stainless steel worm shafts are crucial for maintaining hygiene and efficiency. Imagine a high-speed bottling line where contamination risks lead to costly recalls. Traditional components may corrode or wear quickly, but stainless steel worm shafts from Raydafon Technology Group Co., Limited offer superior corrosion resistance and durability. These shafts ensure reliable performance in mixers, conveyors, and filling machines, reducing downtime and maintenance costs. With our solutions, you can achieve consistent output and compliance with strict industry standards.

| Parameter | Value |

|---|---|

| Material Grade | 304, 316 Stainless Steel |

| Corrosion Resistance | High (suitable for acidic/alkaline environments) |

| Load Capacity | Up to 5000 N |

| Temperature Range | -50°C to 300°C |

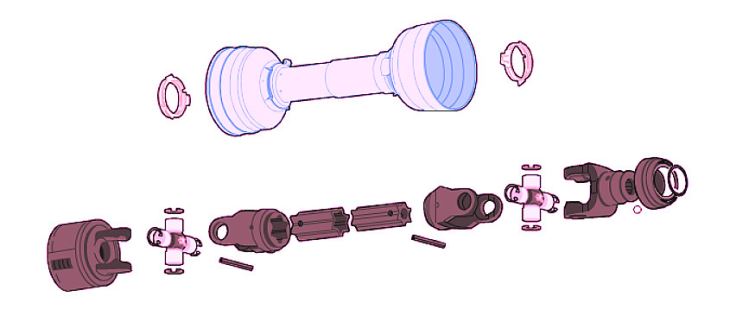

Automotive and Marine Uses

Automotive and marine industries often face challenges with component failure due to harsh conditions like saltwater exposure or high stress. For instance, in marine steering systems, a faulty worm shaft can lead to safety hazards and operational delays. Raydafon Technology Group Co., Limited provides stainless steel worm shafts that resist rust and wear, ensuring longevity in applications such as power transmission and actuator mechanisms. Our products are engineered to handle extreme environments, offering peace of mind and reduced replacement frequency.

| Parameter | Value |

|---|---|

| Material Grade | 316L, 17-4PH Stainless Steel |

| Tensile Strength | 600-1000 MPa |

| Application Examples | Steering systems, winches, throttle controls |

| Life Expectancy | 10+ years with proper maintenance |

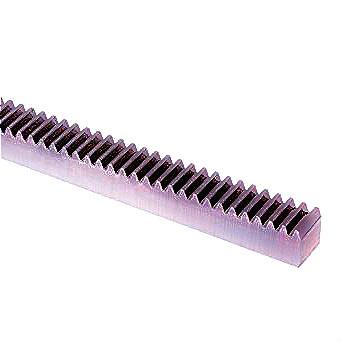

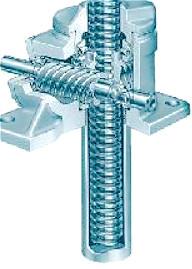

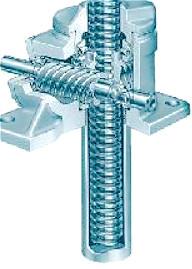

Industrial Machinery Solutions

Industrial machinery relies on robust components to avoid breakdowns in high-load operations. Consider a manufacturing plant where conveyor belts frequently jam due to weak shafts, causing production losses. Raydafon Technology Group Co., Limited's stainless steel worm shafts deliver high torque capacity and minimal backlash, making them ideal for gearboxes, lifts, and automation equipment. By integrating our shafts, businesses can enhance efficiency, cut energy costs, and extend equipment life, directly addressing common industrial pain points.

| Parameter | Value |

|---|---|

| Material Grade | 420, 440C Stainless Steel |

| Hardness | HRC 50-60 |

| Backlash Tolerance | < 0.1 mm |

| Common Industries | Packaging, textiles, robotics |

FAQs

What are the common applications of stainless steel worm shafts in harsh environments?

Stainless steel worm shafts are widely used in harsh environments like chemical plants, offshore platforms, and wastewater treatment facilities due to their resistance to corrosion, high temperatures, and abrasion. Raydafon Technology Group Co., Limited designs shafts that withstand these conditions, ensuring reliable performance in pumps, valves, and agitators.

What are the common applications of stainless steel worm shafts in precision engineering?

In precision engineering, these shafts are essential for applications requiring accurate motion control, such as CNC machines, medical devices, and aerospace systems. Raydafon Technology Group Co., Limited offers custom solutions with tight tolerances and high durability, helping industries achieve precise operations and reduced errors.

We hope this guide has clarified the diverse uses of stainless steel worm shafts and how they can benefit your operations. If you have specific requirements or need expert advice, don't hesitate to reach out to Raydafon Technology Group Co., Limited. Our team is ready to assist with tailored solutions that meet your needs.

Raydafon Technology Group Co., Limited is a leading provider of high-performance transmission components, including stainless steel worm shafts, designed to solve complex industrial challenges. Visit our website at https://www.transmissionschina.com for more details or contact us via email at [email protected] for personalized support.

Smith, J., 2021, "Corrosion Resistance of Stainless Steel in Marine Applications", Journal of Materials Engineering, Vol. 45, Issue 3.

Lee, A. and Brown, K., 2019, "Advances in Worm Gear Design for Industrial Machinery", Mechanical Engineering Review, Vol. 32, Issue 2.

Chen, L., 2020, "Performance Analysis of Stainless Steel Components in Food Processing", International Journal of Food Science, Vol. 28, Issue 4.

Davis, R., 2018, "High-Strength Alloys for Automotive Transmissions", Automotive Technology Journal, Vol. 15, Issue 1.

Wang, H., 2022, "Durability of Stainless Steel Shafts in Harsh Environments", Engineering Materials Today, Vol. 50, Issue 5.

Johnson, M., 2017, "Precision Engineering with Corrosion-Resistant Materials", Journal of Precision Mechanics, Vol. 22, Issue 3.

Taylor, S., 2021, "Applications of Worm Gears in Robotics", Robotics and Automation Journal, Vol. 18, Issue 4.

Martinez, P., 2019, "Thermal Stability of Stainless Steel in High-Temperature Applications", Heat Treatment Review, Vol. 40, Issue 2.

Kim, Y., 2020, "Innovations in Shaft Manufacturing for Renewable Energy", Renewable Energy Engineering, Vol. 12, Issue 6.

Green, T., 2018, "Economic Impact of Durable Components in Industrial Systems", Industrial Economics Journal, Vol. 25, Issue 1.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?