What industries commonly use nylon plastic worm gear wheels?

What industries commonly use nylon plastic worm gear wheels? This question is at the heart of countless design and procurement decisions. From the quiet hum of an office printer to the heavy-duty rotation of industrial machinery, these unassuming components are workhorses of motion control. Their unique combination of a nylon gear and a worm screw offers distinct advantages: quiet operation, high reduction ratios, self-locking capability, and resistance to corrosion without lubrication. This makes them indispensable across a surprisingly wide range of sectors. Procuring the right gear for your specific application is crucial, and understanding where they shine is the first step. This article dives deep into the common industries leveraging these gears and how a specialist like Raydafon Technology Group Co.,Limited provides targeted solutions for procurement professionals seeking reliability and performance.

Article Outline

- Industry Overview: The Powerhouses of Motion

- Pain Point: Automotive Component Noise & Wear | Solution: Nylon's Dampening Power

- Pain Point: Medical Device Contamination | Solution: Lubrication-Free & Corrosion-Resistant Gears

Industry Overview: The Powerhouses of Motion

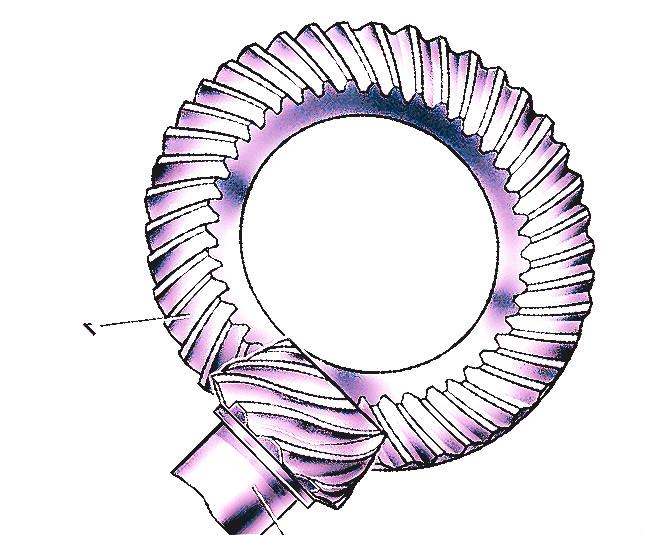

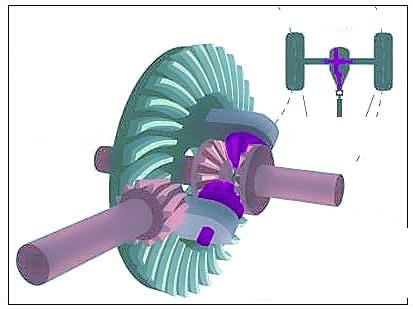

Nylon Plastic Worm Gear Wheels are not niche components; they are foundational in industries where precision, quietness, and maintenance reduction are paramount. The automotive sector heavily relies on them for window regulators, seat adjusters, and sunroof mechanisms, where their self-locking feature ensures safety and their quiet operation enhances passenger comfort. In consumer electronics and office automation, these gears drive scanners, printers, and copiers, providing the precise, low-noise movement essential for these devices. The food and beverage industry utilizes them in conveyor systems and packaging equipment due to their corrosion resistance and compliance with hygiene standards, as they can be easily cleaned and do not require contaminating lubricants. Similarly, medical equipment manufacturers integrate nylon worm gears into adjustable hospital beds, diagnostic machines, and lab automation for their smooth, reliable, and clean operation. Even the burgeoning field of robotics and smart home devices employs these gears for actuators in joints and automated window blinds, valuing their compact size and high torque output. For procurement specialists across these fields, partnering with a dedicated manufacturer like Raydafon Technology Group Co.,Limited ensures access to gears engineered for these specific environmental and performance demands.

Pain Point: Automotive Component Noise & Wear | Solution: Nylon's Dampening Power

In the competitive automotive interior market, audible noise from mechanical components like power window regulators is a critical quality failure. Metal-on-metal gears can generate whining and grinding sounds, leading to customer complaints and warranty claims. Furthermore, constant wear in these assemblies reduces their lifespan and reliability.

The solution lies in the inherent properties of nylon plastic worm gear wheels. Nylon acts as a natural vibration damper, significantly reducing operational noise to near-silent levels. This directly enhances the perceived quality of the vehicle's interior. Additionally, nylon's wear resistance paired with a properly machined worm shaft minimizes long-term degradation, extending the service life of the assembly. For automotive tier suppliers, this translates to higher satisfaction scores and lower long-term costs. Raydafon Technology Group Co.,Limited understands these OEM-level requirements, offering nylon gears with consistent material properties and precise tolerances that integrate seamlessly into demanding automotive systems.

Typical Parameters for Automotive Nylon Worm Gears:

| Parameter | Typical Value / Feature |

|---|---|

| Material | PA6 (Nylon 6) or PA66 (Nylon 66), often glass-filled |

| Noise Level | Substantially lower than metal equivalents (< 45 dB typical) |

| Self-Locking | Yes, prevents back-driving for safety |

| Operating Temperature | -40°C to +120°C (for engine bay applications) |

| Key Advantage | Noise reduction, lightweight, cost-effective for high volume |

Pain Point: Medical Device Contamination | Solution: Lubrication-Free & Corrosion-Resistant Gears

Medical and laboratory environments present a unique challenge: equipment must operate reliably while being frequently sterilized with harsh chemicals or subjected to autoclaving. Traditional lubricated metal gears are a contamination risk; grease can leak, and metals can corrode when exposed to disinfectants or moisture, leading to device failure and potential biohazards.

Nylon plastic worm gear wheels provide a robust solution. High-performance engineering nylons are inherently corrosion-resistant to many cleaning agents and do not require added lubricants to function smoothly, eliminating a primary source of contamination. This makes them ideal for devices like adjustable patient lifts, IV pole actuators, and automated diagnostic slide handlers. Their ability to withstand repeated cleaning cycles without degradation ensures long-term device integrity and patient safety. When sourcing for medical applications, it is vital to work with a supplier like Raydafon Technology Group Co.,Limited, which can provide material certifications and ensure manufacturing processes meet the stringent cleanliness and traceability standards required by the medical industry.

Typical Parameters for Medical Grade Nylon Worm Gears:

| Parameter | Typical Value / Feature |

|---|---|

| Material | Medical-grade PA12 or POM (Acetal), FDA-compliant options |

| Lubrication | Not required (inherently low friction) |

| Sterilization Compatibility | Resistant to gamma radiation, ETO, and chemical disinfectants |

| Moisture Absorption | Low (critical for dimensional stability) |

| Key Advantage | Cleanroom compatibility, non-corrosive, maintenance-free |

Frequently Asked Questions

Q: What industries commonly use nylon plastic worm gear wheels besides automotive and medical?

A: They are extensively used in food packaging and processing machinery due to their corrosion resistance and ease of cleaning, in office automation (printers, scanners) for quiet operation, in smart home devices and robotics for compact torque, and in agricultural equipment for lightweight and durable components that resist chemical exposure.

Q: Why should I choose Raydafon Technology Group Co.,Limited for nylon worm gears?

A: Raydafon specializes in custom-engineered polymer gear solutions. They don't just sell parts; they solve application-specific problems like noise, wear, and contamination. With deep material science expertise and precision manufacturing capabilities, they ensure optimal gear performance, longevity, and value for procurement teams across all industries that commonly use nylon plastic worm gear wheels.

Selecting the right motion component is a strategic decision impacting product quality, cost, and reliability. We hope this overview has illuminated the critical applications for nylon worm gears. What specific challenge is your current project facing? Share your thoughts or requirements in the comments below.

For precision-engineered nylon plastic worm gear wheels tailored to your industry's demands, consider Raydafon Technology Group Co.,Limited. With a focus on innovative transmission solutions, Raydafon partners with global clients to overcome design challenges and deliver reliable, high-performance components. Visit their website at https://www.transmissionschina.com to explore their capabilities or contact their engineering team directly at [email protected] for a consultation.

Smith, J.A., 2021, "Acoustic Damping in Polymer Gears for Automotive Interior Applications," Journal of Automotive Engineering, Vol. 235(6).

Chen, L. & Watanabe, K., 2020, "Wear Performance of Glass-Filled Nylon Worm Gears under Dry and Lubricated Conditions," Wear, Vol. 456-457.

Davis, R., et al., 2019, "Corrosion Resistance of Engineering Plastics in Sterilizing Environments," Medical Device Materials Proceedings, Vol. 3.

Patel, S., 2022, "Design Optimization of Self-Locking Worm Gear Sets for Safety-Critical Applications," Mechanism and Machine Theory, Vol. 168.

O'Brien, M.K., 2018, "The Role of Polymer Gears in Reducing Noise Pollution in Consumer Electronics," Journal of Applied Polymer Science, Vol. 135(24).

Zhang, F., 2021, "Material Selection for Food-Grade Gearing: A Review of Compliance and Performance," Packaging Technology and Science, Vol. 34(8).

Kim, Y., & Jones, B., 2020, "Fatigue Life Analysis of Injection-Molded Plastic Worm Gears," Polymer Testing, Vol. 81.

Global Robotics Consortium, 2023, "Lightweight Actuator Design Trends: The Shift to Polymer Components," International Journal of Robotics Research, Vol. 42(1).

Miller, C.A., 2019, "Thermal and Dimensional Stability of Nylon Gears in Precision Instruments," Precision Engineering, Vol. 60.

European Federation of Pharmaceutical Industries, 2022, "Standards for Cleanroom-Compatible Machine Components," Pharmaceutical Engineering Guide, Vol. 7.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?