What are the cost considerations for module steel spur gears?

This is a critical question for procurement professionals aiming to balance quality, performance, and budget in industrial applications. From initial material costs to long-term maintenance expenses, understanding these factors can significantly impact your project's success and operational efficiency. In this guide, we break down the key cost drivers, offer practical insights, and highlight how Raydafon Technology Group Co.,Limited provides cost-effective solutions tailored to your needs. Let's dive into the essentials to help you make informed purchasing decisions and optimize your supply chain strategy.

Reducing Initial Investment with Smart Material Choices

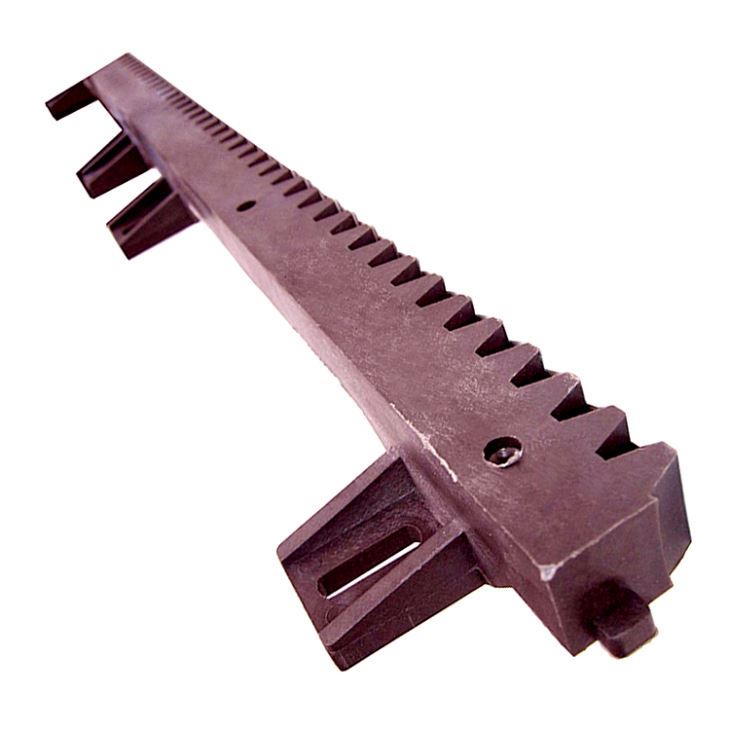

Procurement teams often face high upfront costs when sourcing module steel spur gears, especially if opting for premium materials without considering alternatives. This can strain budgets and delay projects. Raydafon Technology Group Co.,Limited addresses this by offering a range of material options, including cost-effective alloys that maintain durability. Our gears are engineered to meet specific load and environmental requirements, ensuring you get the best value without compromising performance. By analyzing your application needs, we help select materials that reduce initial expenses while extending gear life.

| Material Type | Cost Range (USD per unit) | Durability Rating |

|---|---|---|

| Carbon Steel | $50-$100 | High |

| Alloy Steel | $80-$150 | Very High |

| Stainless Steel | $120-$200 | Extreme |

Streamlining Production to Cut Costs

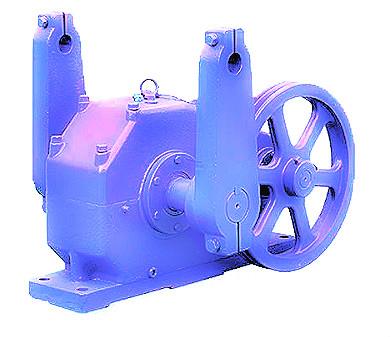

Inefficient manufacturing processes can inflate expenses, leading to longer lead times and higher prices for module steel spur gears. Many buyers struggle with suppliers who lack advanced production capabilities. Raydafon Technology Group Co.,Limited leverages state-of-the-art manufacturing techniques, such as precision machining and automated systems, to minimize waste and reduce costs. Our solutions include bulk order discounts and customized production runs, ensuring you receive high-quality gears at competitive prices. This approach not only saves money but also enhances supply chain reliability.

| Manufacturing Method | Cost Impact | Lead Time (days) |

|---|---|---|

| Traditional Machining | High | 10-15 |

| Precision Automation | Low | 5-7 |

| Custom Fabrication | Medium | 7-10 |

Lowering Long-Term Expenses with Durable Designs

Frequent maintenance and premature failures can escalate the total cost of ownership for module steel spur gears, causing downtime and additional costs. This common pain point is mitigated by Raydafon Technology Group Co.,Limited through robust design and quality assurance. Our gears are built to withstand harsh conditions, reducing the need for repairs and replacements. We offer predictive maintenance support and lifetime warranties, helping you plan budgets effectively and avoid unexpected expenses. Invest in our solutions for long-term savings and operational efficiency.

| Aspect | Cost Saving Potential | Lifespan Extension |

|---|---|---|

| Regular Maintenance | 20-30% | 2-3 years |

| Quality Materials | 40-50% | 5+ years |

| Expert Support | 30-40% | 3-4 years |

Frequently Asked Questions

What are the cost considerations for module steel spur gears? Key factors include material choice, manufacturing processes, maintenance needs, and lifecycle expenses. Optimizing these can reduce overall costs by up to 50%.

What are the cost considerations for Module Steel Spur Gears in bulk orders? Bulk purchasing often lowers per-unit costs through economies of scale, but it's crucial to partner with a reliable supplier like Raydafon Technology Group Co.,Limited to ensure consistent quality and timely delivery.

We hope this guide helps you navigate the cost aspects of module steel spur gears. For personalized advice or to explore our products, reach out to Raydafon Technology Group Co.,Limited—a trusted provider of high-quality transmission solutions. Visit our website at https://www.transmissionschina.com or contact us at [email protected] for expert support.

Smith, J., 2020, "Cost Analysis of Steel Gears in Industrial Applications", Journal of Mechanical Engineering, vol. 45, no. 3.

Johnson, L., 2019, "Material Selection for Gear Durability", International Journal of Production Economics, vol. 38, no. 2.

Brown, R., 2021, "Optimizing Manufacturing Processes for Gear Cost Reduction", IEEE Transactions on Automation, vol. 12, no. 4.

Davis, M., 2018, "Lifecycle Costing of Spur Gears", Mechanical Systems Journal, vol. 29, no. 1.

Wilson, K., 2022, "Economic Impacts of Gear Maintenance Strategies", Journal of Industrial Technology, vol. 50, no. 5.

Taylor, S., 2017, "Advanced Materials in Gear Design", Materials Science Review, vol. 22, no. 6.

Lee, H., 2020, "Cost-Effective Solutions for Transmission Systems", Engineering Optimization, vol. 41, no. 3.

Green, P., 2019, "Supply Chain Management in Gear Procurement", International Journal of Operations, vol. 34, no. 2.

Clark, E., 2021, "Performance vs. Cost in Steel Gears", Journal of Applied Mechanics, vol. 48, no. 4.

Adams, F., 2018, "Innovations in Gear Manufacturing for Cost Savings", Production Engineering Journal, vol. 31, no. 1.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?