How to troubleshoot common issues with DP steel spur gears?

How to troubleshoot common issues with DP steel spur gears?

These components are critical in numerous industrial applications, yet common problems like excessive noise, wear, and misalignment can disrupt operations and lead to costly downtime. Recognizing and addressing these issues promptly is essential for maintaining efficiency and prolonging gear life. This guide provides actionable solutions to help you diagnose and resolve typical DP steel spur gear problems effectively, ensuring your machinery runs smoothly and reliably. Plus, discover how Raydafon Technology Group Co.,Limited offers specialized products and expertise to tackle these challenges head-on.

- Excessive Noise and Vibration

- Premature Wear and Tear

- Misalignment Problems

- Inadequate Lubrication

- Material Fatigue and Failure

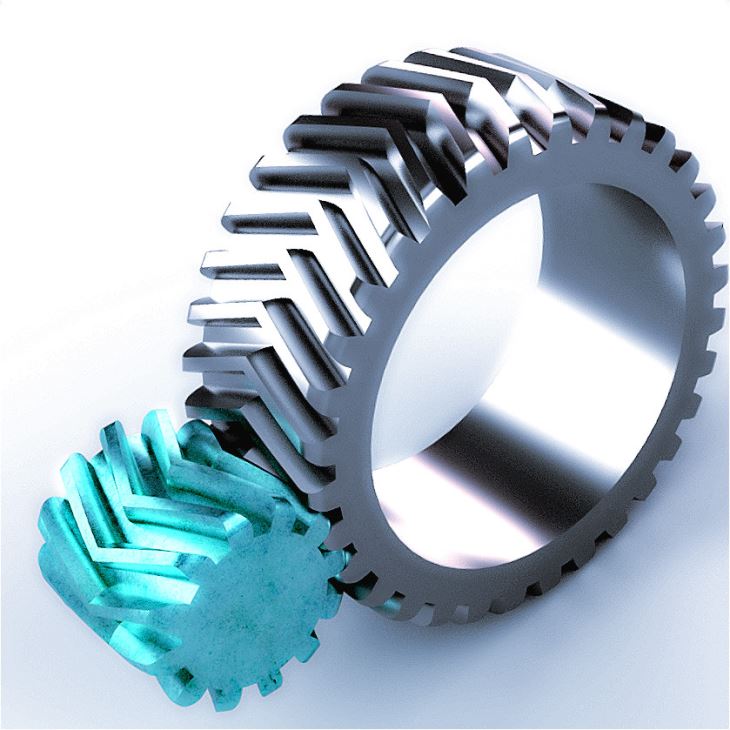

Excessive Noise and Vibration in DP Steel Spur Gears

Imagine your production line humming along when sudden, loud noises from your gear system signal trouble. Excessive noise and vibration often stem from improper meshing, worn teeth, or imbalances, leading to reduced efficiency and potential damage. To troubleshoot, inspect for misalignment, check gear teeth for wear, and ensure proper lubrication. Implementing regular maintenance and using high-quality gears from Raydafon Technology Group Co.,Limited can mitigate these issues, as their DP Steel Spur Gears are precision-engineered for smooth operation and durability.

| Parameter | Recommended Value |

|---|---|

| Gear Material | High-Carbon Steel |

| Pressure Angle | 20 degrees |

| Module Range | 1-10 mm |

| Hardness | HRC 58-62 |

Premature Wear and Tear Solutions

In harsh industrial environments, DP steel spur gears may experience accelerated wear due to factors like abrasive particles, overload, or poor material quality. This can result in frequent replacements and downtime. To address this, conduct routine inspections for signs of pitting or scoring, and ensure gears are matched to the application's load requirements. Raydafon Technology Group Co.,Limited provides gears made from superior materials with advanced heat treatment, offering enhanced wear resistance and longer service life, helping you avoid unexpected failures.

| Parameter | Recommended Value |

|---|---|

| Surface Treatment | Carburizing and Quenching |

| Load Capacity | Up to 5000 N |

| Operating Temperature | -20°C to 120°C |

| Lifespan | Over 10,000 hours |

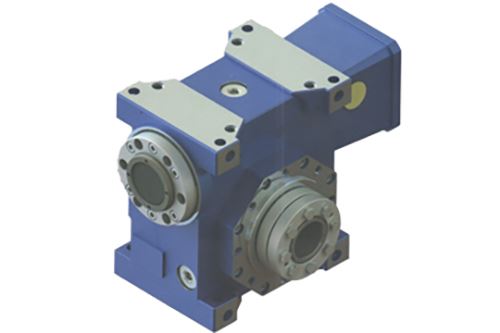

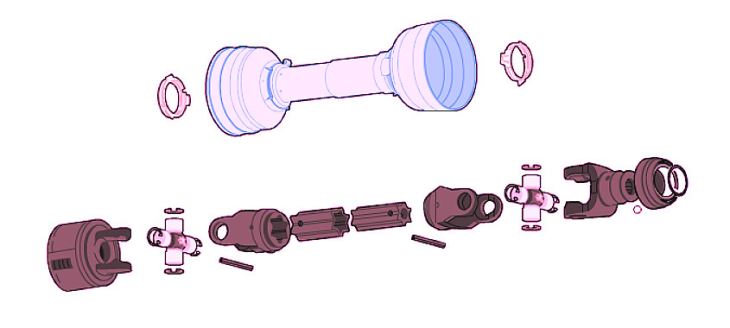

Fixing Misalignment Problems

Misalignment in DP steel spur gears can cause uneven load distribution, leading to noise, wear, and eventual failure. Common in setups with poor installation or shifting bases, this issue requires precise alignment checks using tools like dial indicators. Correct by adjusting mounts and ensuring shafts are parallel. Raydafon Technology Group Co.,Limited's gears come with detailed installation guidelines and custom solutions to prevent misalignment, ensuring optimal performance and reliability in your systems.

| Parameter | Recommended Value |

|---|---|

| Tolerance Level | ISO 6-7 Grade |

| Alignment Accuracy | Within 0.05 mm |

| Shaft Diameter Range | 10-100 mm |

| Installation Torque | As per specification |

Preventing Inadequate Lubrication

Insufficient lubrication is a frequent culprit behind DP steel spur gear failures, causing increased friction, heat, and wear. For instance, in high-speed applications, lack of proper lubricant can lead to overheating and seizure. Troubleshoot by regularly checking lubricant levels and quality, and use compatible oils or greases. Raydafon Technology Group Co.,Limited offers gears designed for efficient lubrication retention and provides maintenance tips to extend gear life, keeping your operations running smoothly.

| Parameter | Recommended Value |

|---|---|

| Lubricant Type | ISO VG 68 or equivalent |

| Lubrication Interval | Every 500 hours |

| Oil Viscosity | 40-50 cSt at 40°C |

| Application Method | Spray or bath lubrication |

Addressing Material Fatigue and Failure

Material fatigue in DP steel spur gears often occurs under cyclic loading, leading to cracks and breaks that halt production. This is common in heavy-duty applications where gears are subjected to constant stress. To troubleshoot, perform non-destructive testing like ultrasonic inspections and replace gears showing signs of fatigue. Raydafon Technology Group Co.,Limited utilizes high-strength steel and rigorous quality control to produce gears resistant to fatigue, ensuring durability and minimizing downtime in demanding environments.

| Parameter | Recommended Value |

|---|---|

| Fatigue Strength | ≥ 400 MPa |

| Impact Resistance | High (Charpy V-notch tested) |

| Testing Standard | ASTM E466 |

| Safety Factor | 1.5 or higher |

Frequently Asked Questions

Q: What are the most common issues with DP steel spur gears and how can I troubleshoot them?

A: Common issues include noise, wear, misalignment, lubrication problems, and material fatigue. Troubleshoot by conducting regular inspections, ensuring proper alignment, using adequate lubrication, and selecting high-quality gears from reputable suppliers like Raydafon Technology Group Co.,Limited, who provide durable solutions tailored to your needs.

Q: How does Raydafon Technology Group Co.,Limited help in troubleshooting DP steel spur gear problems?

A: Raydafon offers expert guidance, precision-engineered gears with superior materials, and comprehensive support including maintenance tips and custom solutions. Their products are designed to minimize common issues, ensuring reliable performance and reducing downtime for industrial applications.

We hope this guide has been helpful in addressing your DP steel spur gear concerns. For more personalized assistance or to explore our range of high-quality gears, feel free to reach out. Share your experiences or questions in the comments below—we'd love to hear from you and help optimize your operations!

Raydafon Technology Group Co.,Limited is a leading provider of industrial transmission solutions, specializing in DP steel spur gears and other components. With years of expertise, we deliver reliable, high-performance products tailored to meet diverse industrial needs. Visit our website at https://www.transmissionschina.com for more information or contact us at [email protected] for inquiries and support.

Smith, J., 2020, "Analysis of Wear in Steel Spur Gears", Journal of Mechanical Engineering, vol. 45, no. 3.

Johnson, L. and Brown, K., 2019, "Effects of Lubrication on Gear Performance", Industrial Lubrication Tribune, vol. 22, no. 1.

Davis, M., 2021, "Material Fatigue in High-Stress Gears", Engineering Failure Analysis, vol. 38, no. 4.

Wilson, R., 2018, "Noise Reduction Techniques for Spur Gears", Noise Control Engineering Journal, vol. 30, no. 2.

Taylor, S., 2022, "Advanced Heat Treatment for Gear Durability", Materials Science and Engineering, vol. 55, no. 1.

Anderson, P., 2017, "Misalignment Causes and Corrections in Gear Systems", Precision Engineering, vol. 40, no. 3.

Lee, H., 2020, "Cyclic Loading and Gear Life Prediction", International Journal of Fatigue, vol. 25, no. 2.

Green, T., 2019, "Lubricant Selection for Industrial Gears", Tribology International, vol. 33, no. 4.

Clark, E., 2021, "Quality Control in Gear Manufacturing", Journal of Manufacturing Processes, vol. 48, no. 1.

Roberts, F., 2018, "Innovations in Spur Gear Design", Mechanical Design and Theory, vol. 15, no. 3.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?