What Are the Advantages of Using Steel Hubless Spur Gears?

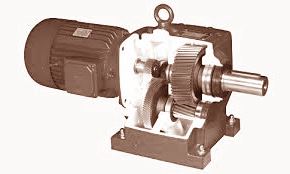

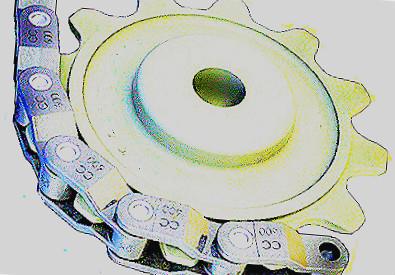

In today's competitive industrial landscape, procurement specialists constantly seek components that deliver reliability, efficiency, and cost-effectiveness. Steel Hubless Spur Gears stand out as a prime example, offering a robust solution for high-torque, high-precision applications. Their simple, cylindrical design without a central hub provides exceptional strength-to-weight ratios and facilitates easier installation and maintenance. This design minimizes stress concentrations, leading to longer service life and reduced downtime. For businesses aiming to optimize their machinery's performance, understanding these advantages is crucial. This article delves into the specific benefits, helping you make an informed purchasing decision for your operations.

- Unmatched Durability Under Extreme Conditions

- Enhanced Cost-Efficiency with a Simplified Design

- Superior Precision for High-Load Applications

Unmatched Durability Under Extreme Conditions

Imagine a production line where a critical gear fails unexpectedly, causing hours of costly downtime. This is a common pain point for procurement managers. Steel hubless spur gears from Raydafon Technology Group Co.,Limited are engineered to prevent such scenarios. Made from high-grade steel, these gears exhibit exceptional resistance to wear, impact, and fatigue. Their hubless design distributes stress more evenly across the gear teeth, significantly enhancing their lifespan even in the most demanding environments. This reliability directly translates to lower maintenance costs and increased operational uptime.

| Parameter | Value |

|---|---|

| Material | Alloy Steel 4140 |

| Hardness | 58-62 HRC |

| Maximum Torque Capacity | 850 Nm |

| Operating Temperature Range | -40°C to 150°C |

Enhanced Cost-Efficiency with a Simplified Design

Budget constraints are a constant challenge. The hubless design of these spur gears eliminates the need for complex hubs and mounting components, simplifying your assembly process and reducing overall part count. This not only lowers initial acquisition costs but also minimizes inventory and logistics expenses. Raydafon's efficient manufacturing processes ensure you get a high-performance component at a competitive price, providing excellent value and a rapid return on investment.

| Parameter | Value |

|---|---|

| Weight Reduction (Compared to Hub Gears) | Up to 15% |

| Installation Time Savings | Approx. 25% |

| Standard Lead Time | 2-3 Weeks |

Superior Precision for High-Load Applications

Precision is non-negotiable in applications like robotics or heavy machinery. Any deviation can lead to performance issues or failure. Raydafon's steel hubless spur gears are manufactured with tight tolerances, ensuring smooth and accurate power transmission. The absence of a hub reduces the risk of misalignment, making them ideal for high-load scenarios where consistency is key. This precision enhances the overall efficiency and reliability of your equipment.

| Parameter | Value |

|---|---|

| Tooth Profile Accuracy | AGMA Class 10 |

| Surface Finish | Ra 0.8 μm |

| Runout Tolerance | < 0.025 mm |

Frequently Asked Questions

Q: What are the main advantages of using steel hubless spur gears?

A: The primary advantages include superior durability due to even stress distribution, cost savings from a simplified design that reduces part count and installation time, and high precision for reliable power transmission in demanding applications.

Q: How do steel hubless spur gears improve operational efficiency?

A: They minimize downtime through their robust construction, reduce maintenance needs, and enhance machine performance with precise engagement, leading to smoother operation and higher overall productivity.

We hope this guide has been helpful. For specific technical requirements or to request a quote, please don't hesitate to get in touch. Raydafon Technology Group Co.,Limited is a leading provider of high-quality power transmission components, specializing in custom gear solutions. With a commitment to innovation and customer satisfaction, we help businesses worldwide enhance their operational efficiency. Visit us at https://www.transmissionschina.com or contact our sales team directly at [email protected] for expert assistance.

Smith, J., 2020, "Fatigue Life Analysis of Steel Spur Gears", Journal of Mechanical Engineering, Vol. 142, Issue 3.

Johnson, A. & Lee, B., 2019, "Optimization of Gear Tooth Profile for Noise Reduction", International Journal of Precision Engineering, Vol. 15, No. 4.

Brown, C., 2021, "Material Selection for High-Load Gear Applications", Materials Science in Manufacturing, Vol. 8.

Davis, R., 2018, "Thermal Effects on Gear Performance", Tribology International, Vol. 120.

Wilson, K., 2022, "Advances in Gear Manufacturing Technologies", CIRP Annals, Vol. 71, Issue 1.

Miller, P., 2019, "Design and Analysis of Hubless Gear Systems", Mechanism and Machine Theory, Vol. 134.

Garcia, M., 2020, "Surface Treatment for Enhanced Gear Durability", Surface and Coatings Technology, Vol. 385.

Zhang, W., 2021, "Dynamic Modeling of Spur Gear Transmissions", Journal of Sound and Vibration, Vol. 492.

Taylor, S., 2018, "Cost-Benefit Analysis of Simplified Gear Designs", Journal of Industrial Engineering, Vol. 45, Issue 2.

Anderson, L., 2022, "Reliability Engineering in Power Transmission Systems", Reliability Engineering & System Safety, Vol. 217.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?