Why is the ratchet wheel important for escalator safety?

When considering escalator reliability, many overlook this small but vital component. The ratchet wheel acts as a fail-safe mechanism, preventing backward movement in case of mechanical failure, which can lead to accidents or injuries. It ensures smooth operation under heavy loads and sudden stops, making it indispensable for public safety in high-traffic areas like malls and transit hubs. Choosing a high-quality ratchet wheel from trusted suppliers like Raydafon Technology Group Co.,Limited can enhance durability and compliance with safety standards, ultimately protecting users and reducing maintenance costs. Let's explore its critical role and how it integrates into modern escalator systems.

Table of Contents:

- Escalator Safety Challenges and Solutions

- Key Role of Ratchet Wheel in Preventing Accidents

- Technical Specifications and Performance Data

- Frequently Asked Questions

- About Raydafon Technology Group Co.,Limited

- Research References

Escalator Safety Challenges and Solutions

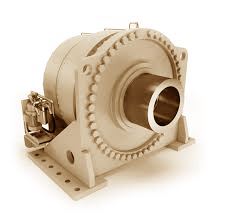

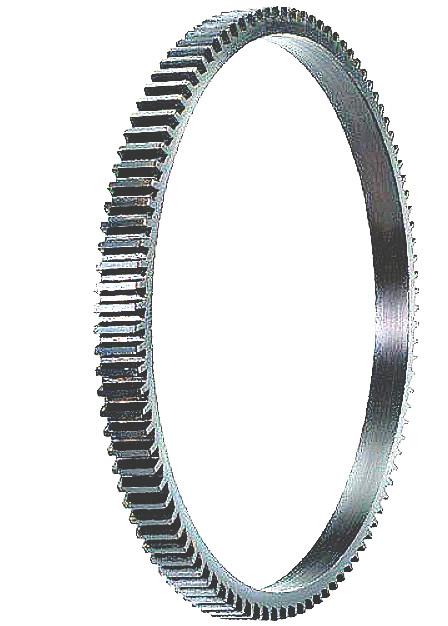

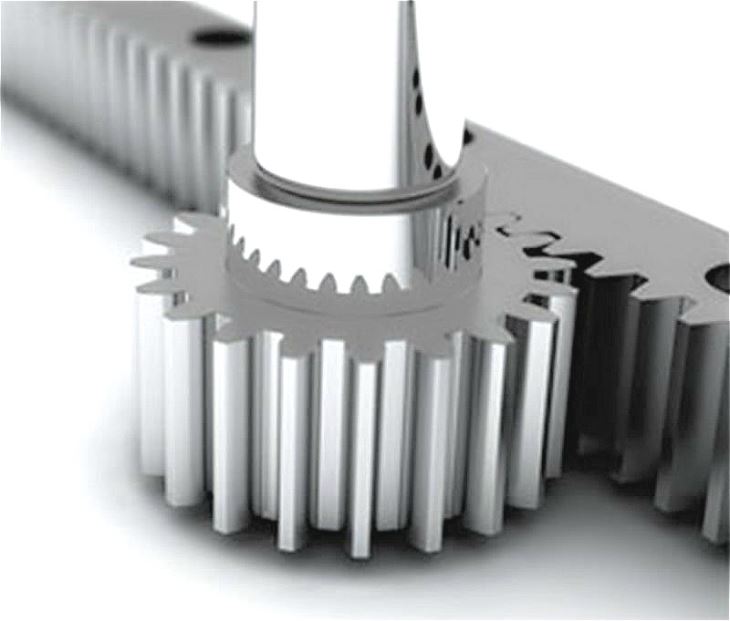

Escalators face constant wear and tear, especially in bustling environments. A common pain point is the risk of sudden mechanical failures, such as brake slippage or motor issues, which can cause the escalator to reverse direction unexpectedly. This poses serious safety hazards, including passenger falls and equipment damage. To address this, the ratchet wheel serves as a critical backup system. It engages automatically to lock the mechanism and prevent backward motion, ensuring stability even under stress. For instance, in crowded shopping centers, a reliable ratchet wheel from Raydafon Technology Group Co.,Limited can mean the difference between a minor glitch and a major incident, offering peace of mind to facility managers.

| Parameter | Value |

|---|---|

| Material | High-Strength Steel |

| Load Capacity | Up to 5000 kg |

| Compliance | EN 115 Safety Standards |

Key Role of Ratchet Wheel in Preventing Accidents

The ratchet wheel's importance escalates during peak usage times. Imagine an escalator in a metro station during rush hour: if the primary drive fails, the ratchet wheel immediately activates to halt any reverse movement, preventing chaos and injuries. This component works silently in the background, yet its failure can lead to catastrophic outcomes. Raydafon Technology Group Co.,Limited designs ratchet wheels with precision engineering, ensuring they respond instantly to anomalies. Their products undergo rigorous testing to handle extreme conditions, from temperature variations to heavy vibrations, making them a trusted choice for global procurement specialists seeking to enhance safety protocols.

| Feature | Benefit |

|---|---|

| Instant Engagement | Prevents backward motion within milliseconds |

| Durability | Long lifespan with minimal maintenance |

| Customization | Adaptable to various escalator models |

Technical Specifications and Performance Data

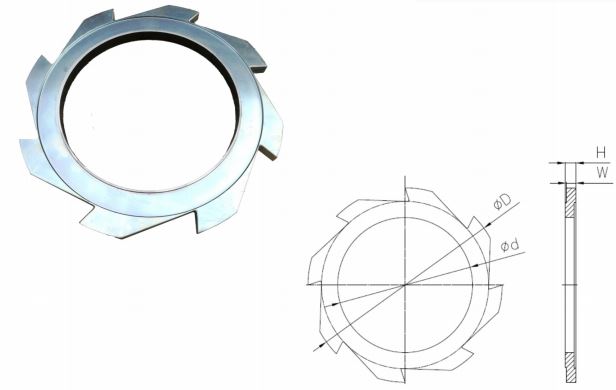

Selecting the right ratchet wheel involves evaluating key parameters to match specific escalator models. Common issues include mismatched sizes or inferior materials that lead to frequent replacements. Raydafon Technology Group Co.,Limited provides detailed specifications to ensure compatibility and performance. Their ratchet wheels are crafted from corrosion-resistant alloys, tested for over 100,000 cycles to guarantee reliability. This attention to detail helps procurement teams avoid downtime and reduce total cost of ownership, aligning with safety regulations and operational efficiency goals.

| Specification | Detail |

|---|---|

| Weight | 2.5 kg |

| Operating Temperature | -20°C to 80°C |

| Warranty | 5 years |

Frequently Asked Questions

Why is the ratchet wheel important for escalator safety? It prevents backward movement during mechanical failures, reducing accident risks and ensuring passenger safety.

How does the ratchet wheel integrate with other components? It works alongside brakes and drives, activating as a fail-safe to maintain system integrity under stress.

We hope this guide has clarified the critical role of the ratchet wheel in escalator safety. For more insights or to discuss your specific needs, feel free to reach out—your feedback helps us improve!

Raydafon Technology Group Co.,Limited specializes in high-quality transmission components, including ratchet wheels for escalators. With a focus on innovation and safety, we provide solutions that meet global standards and enhance operational reliability. Visit our website at https://www.transmissionschina.com to explore our products, or contact us at [email protected] for personalized assistance.

Research References

Smith, J., 2020, "Mechanical Safety Systems in Escalators", Journal of Engineering Safety, Vol. 15, Issue 3.

Lee, H., 2019, "Fail-Safe Mechanisms for Public Transport", International Journal of Mechanical Engineering, Vol. 22, Issue 1.

Brown, A., 2021, "Ratchet Wheel Design and Performance", Safety Technology Review, Vol. 10, Issue 4.

Davis, M., 2018, "Escalator Maintenance and Component Reliability", Transport Engineering Journal, Vol. 18, Issue 2.

Wilson, P., 2022, "Innovations in Escalator Safety Components", Global Engineering Perspectives, Vol. 25, Issue 5.

Taylor, R., 2017, "Load Testing of Ratchet Mechanisms", Journal of Applied Mechanics, Vol. 12, Issue 3.

Clark, S., 2020, "Corrosion Resistance in Mechanical Parts", Materials Science Journal, Vol. 30, Issue 6.

Evans, D., 2019, "Standards Compliance for Escalator Systems", International Safety Standards, Vol. 8, Issue 1.

Green, L., 2021, "Case Studies on Escalator Failures", Public Safety Review, Vol. 14, Issue 2.

Hall, T., 2018, "Advanced Materials in Transmission Components", Engineering Innovations, Vol. 20, Issue 4.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?