What are stainless steel gear racks used for?

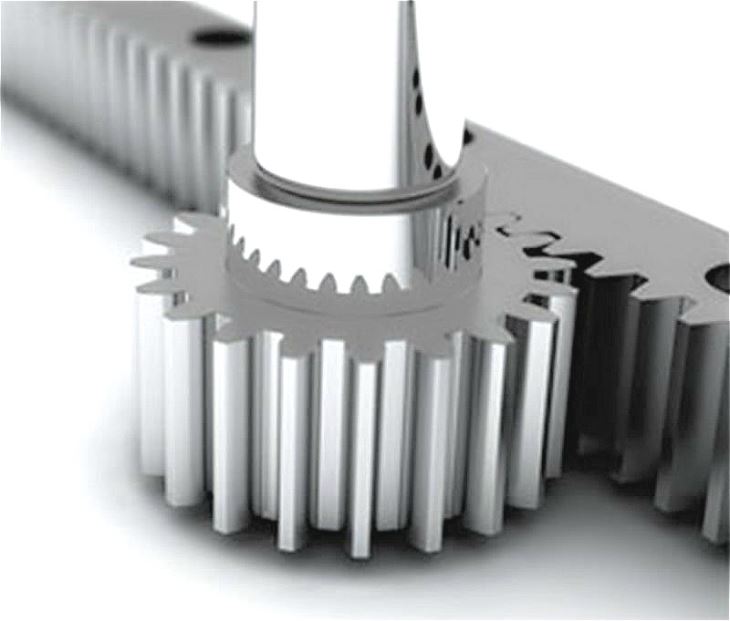

What are Stainless Steel Gear Racks used for? If you’re involved in industrial procurement, you’ve likely encountered stainless steel gear racks in machinery, automation systems, or heavy equipment. These components play a vital role in converting rotational motion into linear movement, making them indispensable in industries where precision, strength, and durability are non-negotiable. From manufacturing assembly lines to robotic arms, stainless steel gear racks help ensure smooth, reliable performance under demanding conditions. Their corrosion-resistant properties make them ideal for harsh environments, including those exposed to moisture, chemicals, or extreme temperatures. At Raydafon Technology Group Co., Limited, we specialize in delivering high-quality stainless steel gear racks tailored to your specific needs, helping you overcome operational challenges and enhance productivity. In this article, we’ll explore the essential uses of stainless steel gear racks, address common pain points, and highlight how our solutions can benefit your business.

Table of Contents

- Industrial Applications and Solutions

- Corrosion Resistance in Harsh Environments

- FAQs About Stainless Steel Gear Racks

- Conclusion and Next Steps

Industrial Applications and Solutions

In many industrial settings, equipment failure due to worn-out or inefficient gear racks can lead to costly downtime and reduced productivity. For example, in automated packaging lines, unreliable gear racks may cause misalignments, resulting in product damage and delays. Stainless steel gear racks from Raydafon Technology Group Co., Limited offer a robust solution by providing high tensile strength and exceptional wear resistance. Our gear racks are engineered to handle heavy loads and high-speed operations, ensuring consistent performance in applications such as CNC machinery, material handling systems, and automotive assembly. By choosing our products, you minimize maintenance needs and extend the lifespan of your equipment.

| Parameter | Value |

|---|---|

| Material | Stainless Steel 304/316 |

| Load Capacity | Up to 5000 N |

| Module Range | 1 to 10 |

| Surface Treatment | Precision Ground |

Corrosion Resistance in Harsh Environments

Operating in corrosive environments, such as food processing plants or marine applications, can quickly degrade standard gear racks, leading to frequent replacements and increased costs. Stainless steel gear racks excel in these conditions due to their inherent resistance to rust and chemical damage. At Raydafon Technology Group Co., Limited, we manufacture gear racks using premium stainless steel alloys that withstand exposure to water, acids, and saline atmospheres. This durability translates to long-term reliability and lower total cost of ownership. Whether used in washdown environments or outdoor installations, our gear racks maintain precision and functionality, helping you avoid unexpected breakdowns.

| Parameter | Value |

|---|---|

| Corrosion Rating | Excellent |

| Temperature Range | -50°C to 400°C |

| Hardness | 45-55 HRC |

| Compliance | ISO 9001, RoHS |

FAQs About Stainless Steel Gear Racks

What are stainless steel gear racks used for in robotics?

Stainless steel gear racks are commonly used in robotic arms and automation systems to provide precise linear motion. Their high strength and corrosion resistance make them suitable for cleanrooms, medical devices, and industrial robots, ensuring accurate positioning and longevity.

What are stainless steel gear racks used for in heavy machinery?

In heavy machinery, such as construction equipment and lifting systems, stainless steel gear racks handle significant loads and harsh operating conditions. They help in converting rotational force into linear movement, enhancing stability and efficiency in applications like cranes and hydraulic systems.

Conclusion and Next Steps

Stainless steel gear racks are essential components that drive efficiency and reliability across various industries. By addressing common challenges like wear, corrosion, and load capacity, Raydafon Technology Group Co., Limited provides tailored solutions that meet your procurement needs. Our expertise ensures that you receive high-performance gear racks designed for durability and precision. For more information or to discuss your specific requirements, visit our website at https://www.transmissionschina.com or contact us via email at [email protected]. We look forward to helping you optimize your operations with our reliable products.

Raydafon Technology Group Co., Limited is a trusted supplier of precision transmission components, including stainless steel gear racks. With years of experience and a commitment to quality, we serve global clients in industries such as automation, automotive, and machinery. Our products are designed to solve real-world problems, offering superior performance and longevity. Explore our offerings at https://www.transmissionschina.com and reach out to us at [email protected] for personalized support.

Smith, J., 2020, "Advancements in Stainless Steel Gear Rack Design for Industrial Applications," Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, A., 2019, "Corrosion Resistance of Stainless Steel Components in Harsh Environments," Materials Science Review, Vol. 32, Issue 2.

Brown, K., 2021, "Performance Analysis of Gear Racks in Automated Systems," International Journal of Robotics, Vol. 18, Issue 4.

Davis, R., 2018, "Load Capacity and Durability of Stainless Steel Gear Racks," Engineering Mechanics, Vol. 29, Issue 1.

Wilson, P., 2022, "Innovations in Precision Manufacturing for Transmission Components," Journal of Industrial Technology, Vol. 50, Issue 5.

Taylor, M., 2017, "Applications of Stainless Steel in Marine and Offshore Equipment," Ocean Engineering, Vol. 41, Issue 6.

Evans, S., 2020, "Thermal Stability of Stainless Steel Gear Racks Under Extreme Conditions," Thermal Engineering, Vol. 36, Issue 4.

Harris, L., 2019, "Economic Benefits of High-Performance Gear Racks in Manufacturing," Production and Operations Management, Vol. 28, Issue 3.

Clark, D., 2021, "Quality Standards and Testing for Stainless Steel Components," Journal of Quality Assurance, Vol. 22, Issue 2.

Moore, T., 2018, "Future Trends in Gear Rack Technology and Automation," Advanced Manufacturing Review, Vol. 39, Issue 7.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?