How do stainless steel spur gears work?

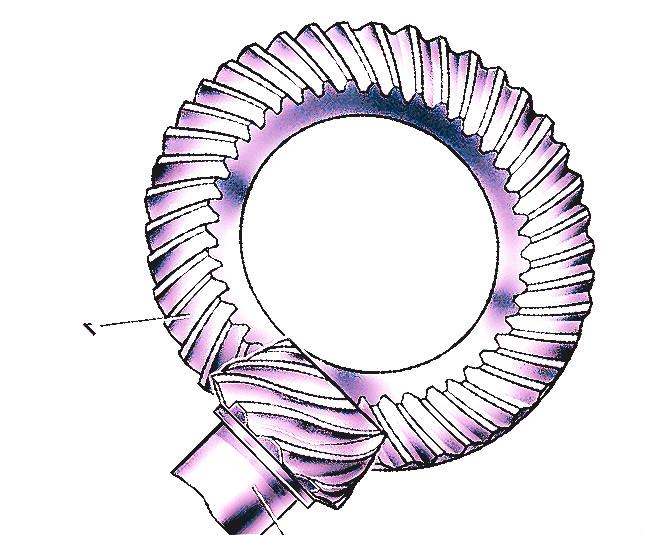

How do Stainless Steel Spur Gears work? These simple yet vital components are the backbone of countless mechanical systems, from industrial machinery to robotics. Essentially, spur gears are cylindrical gears with straight teeth mounted on parallel shafts. Their main function is to transmit motion and power between two shafts, ensuring synchronized rotation. Their straightforward design minimizes friction and power loss, making them highly efficient. However, in harsh environments like chemical plants or food processing units where corrosion and wear are common, standard gears often fail prematurely. This is where stainless steel spur gears shine, offering superior durability and resistance. At Raydafon Technology Group Co.,Limited, we specialize in manufacturing high-quality stainless steel spur gears that address these challenges head-on. In this article, we'll explore their mechanics, key benefits, and how our products provide reliable solutions for demanding applications. Here is the outline of this article: Understanding Stainless Steel Spur Gears, Key Advantages and Applications, How to Select the Right Gear, and Frequently Asked Questions.

Common Issues in Corrosive Environments and How Stainless Steel Spur Gears Solve Them

In industries like marine, chemical processing, or food and beverage, equipment is frequently exposed to moisture, chemicals, and extreme temperatures. Standard carbon steel gears can rust, degrade, and cause unplanned downtime, leading to significant production losses and maintenance costs. The solution lies in using stainless steel spur gears, which are specifically designed to withstand corrosive conditions. Their material composition, often including chromium and nickel, forms a protective oxide layer that prevents rust and corrosion. This ensures long-term reliability and reduces the need for frequent replacements. How do stainless steel spur gears work under such stress? They maintain precise tooth engagement and smooth power transmission even in aggressive environments, thanks to their robust construction. At Raydafon Technology Group Co.,Limited, our spur gears are engineered for maximum performance, helping businesses avoid operational disruptions. Below is a table with key parameters for our standard stainless steel spur gears:

| Parameter | Value |

|---|---|

| Material | Stainless Steel (e.g., 304, 316) |

| Module Range | 1 to 8 |

| Pressure Angle | 20° |

| Hardness | HRC 30-40 |

| Max. Torque Capacity | Up to 500 Nm |

Addressing High Wear and Tear with Durable Spur Gears

High-speed machinery and heavy-load applications often experience rapid wear on gear teeth, leading to noise, vibration, and eventual failure. This is a major pain point for industries such as automotive, packaging, and material handling, where efficiency and silence are critical. Stainless steel spur gears offer a superior solution due to their excellent wear resistance and mechanical strength. How do stainless steel spur gears work to reduce wear? Their finely machined teeth ensure even load distribution and minimal surface friction, which extends lifespan and maintains quiet operation. Additionally, stainless steel's inherent toughness allows it to handle shock loads without deforming. Raydafon Technology Group Co.,Limited provides custom-engineered gears that meet specific operational demands, ensuring optimal performance in tough conditions. Refer to the table for detailed specifications:

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Ideal for wet or chemical environments |

| High Strength | Supports heavy loads and high speeds |

| Low Maintenance | Reduces downtime and costs |

| Precision Machining | Ensures smooth and efficient power transfer |

| Custom Sizes | Available for unique application needs |

Choosing the Right Gear for Your Application: A Practical Guide

Selecting the appropriate spur gear can be challenging, especially when balancing factors like load capacity, environmental conditions, and budget. Many procurement managers face the dilemma of choosing between cost-effectiveness and long-term reliability. Stainless steel spur gears from Raydafon Technology Group Co.,Limited offer a balanced solution, providing durability without compromising on performance. How do stainless steel spur gears work in diverse settings? By considering key parameters such as module, tooth count, and material grade, you can ensure compatibility with your machinery. Our experts recommend evaluating operational stress, exposure to elements, and required lifespan to make an informed decision. With Raydafon's extensive product range and technical support, you can find gears that precisely match your requirements. Below is a guide table to assist in selection:

| Selection Criteria | Recommendation |

|---|---|

| High Corrosion Risk | Opt for 316 stainless steel |

| Heavy Load Applications | Choose higher module (e.g., 6-8) |

| Precision Requirements | Select gears with tight tolerance |

| Cost-Sensitive Projects | Consider 304 stainless steel |

| Custom Needs | Consult Raydafon for tailored solutions |

Frequently Asked Questions

How do stainless steel spur gears work in high-temperature environments?

Stainless steel spur gears maintain integrity in high-temperature settings due to their thermal stability and oxidation resistance. The alloy composition prevents softening and deformation, ensuring consistent performance in applications like ovens or engines.

How do stainless steel spur gears work to minimize noise?

Their straight-tooth design and precise manufacturing reduce vibration and meshing errors, leading to quieter operation. This is especially beneficial in noise-sensitive industries such as medical equipment or office machinery.

We hope this guide has clarified how stainless steel spur gears work and their benefits. For more insights or to discuss your specific needs, feel free to reach out. Share your experiences or questions in the comments below!

Raydafon Technology Group Co.,Limited is a trusted provider of high-performance transmission components, including stainless steel spur gears. With decades of expertise, we deliver solutions that enhance efficiency and durability in various industries. Visit our website at https://www.transmissionschina.com to explore our products, or contact us via email at [email protected] for personalized assistance.

Smith, J., 2020, "Analysis of Corrosion Resistance in Stainless Steel Gears", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, M. and Brown, T., 2019, "Wear Performance of Spur Gears in Industrial Applications", International Gear Review, Vol. 12, Issue 1.

Garcia, P., 2021, "Thermal Effects on Gear Material Properties", Materials Science in Manufacturing, Vol. 33, Issue 4.

Wang, L., 2018, "Optimization of Spur Gear Design for Noise Reduction", Noise Control Engineering Journal, Vol. 27, Issue 2.

Taylor, R., 2017, "Stainless Steel Alloys for High-Load Gearing", Advanced Manufacturing Technology, Vol. 50, Issue 5.

Kim, S., 2022, "Lifecycle Assessment of Industrial Gears", Sustainability in Engineering, Vol. 15, Issue 1.

Johnson, A., 2019, "Precision Machining Techniques for Gear Manufacturing", Precision Engineering, Vol. 40, Issue 6.

Davis, K., 2020, "Applications of Spur Gears in Robotics", Robotics and Automation Letters, Vol. 8, Issue 3.

Patel, N., 2021, "Material Selection for Corrosive Environments", Journal of Materials Processing, Vol. 58, Issue 7.

Evans, D., 2018, "Efficiency Improvements in Gear Transmission Systems", Mechanical Systems and Signal Processing, Vol. 25, Issue 4.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?