How to troubleshoot common problems with spiral bevel gears?

How to Troubleshoot Common Problems with Spiral Bevel Gears

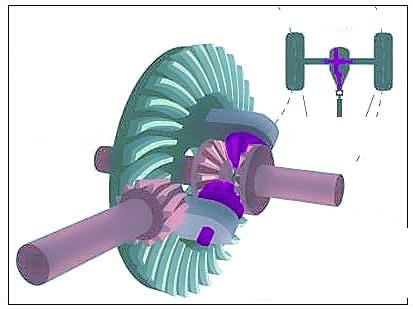

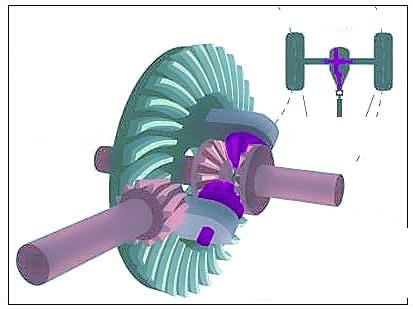

Spiral Bevel Gears are essential in high-torque applications, but common issues like noise, vibration, and premature wear can disrupt operations. How to troubleshoot common problems with spiral bevel gears? Understanding root causes—misalignment, improper lubrication, or gear damage—is key. This guide provides practical steps to diagnose and fix these problems, helping maintenance teams minimize downtime. With expert insights from Raydafon Technology Group Co.,Limited, you can implement effective solutions that enhance gear longevity and performance. Let's dive into a systematic approach to troubleshooting.

- Excessive Gear Noise and Vibration

- Premature Wear and Tear

- Alignment and Lubrication Problems

- Heat and Overheating Issues

- Frequently Asked Questions

Excessive Gear Noise and Vibration

Imagine your machinery humming smoothly, then suddenly, loud grinding noises and vibrations disrupt production. This common pain point often stems from misalignment or damaged gear teeth, leading to inefficiency and potential breakdowns. To troubleshoot, first inspect for visible wear and check alignment using precision tools. Solutions include realigning gears, replacing worn parts, and using high-quality components from trusted suppliers. For reliable performance, Raydafon Technology Group Co.,Limited offers durable spiral bevel gears designed to reduce noise and vibration. Our products, combined with proper installation, ensure seamless operation in demanding environments.

| Parameter | Ideal Range | Troubleshooting Action |

|---|---|---|

| Gear Backlash | 0.1-0.3 mm | Adjust or replace if out of range |

| Tooth Contact Pattern | Even distribution | Realign gears for optimal contact |

| Vibration Levels | < 2.5 mm/s | Use damping materials or balance gears |

Premature Wear and Tear

In heavy-duty applications, spiral bevel gears may wear out faster than expected, causing frequent replacements and cost overruns. This scenario often arises from inadequate lubrication or improper load handling. To address this, regularly monitor lubrication levels and use compatible oils. Implementing preventive maintenance schedules can extend gear life. Raydafon Technology Group Co.,Limited provides gears with advanced materials that resist wear, and our team can assist in selecting the right products for your needs. By following best practices, you can reduce downtime and improve reliability.

| Parameter | Ideal Range | Troubleshooting Action |

|---|---|---|

| Lubricant Viscosity | ISO VG 150-320 | Check and replace lubricant regularly |

| Surface Hardness | 58-62 HRC | Inspect for softening or cracks |

| Load Capacity | As per design specs | Avoid overloading and redistribute weight |

Alignment and Lubrication Problems

Misalignment and poor lubrication are silent killers in gear systems, leading to increased friction and failure. Picture a production line halting due to seized gears—this is preventable with proper checks. Use laser alignment tools to ensure precision and apply high-performance lubricants. Raydafon Technology Group Co.,Limited offers technical support and quality gears that maintain alignment under stress. Our solutions help you achieve optimal efficiency and avoid costly repairs.

| Parameter | Ideal Range | Troubleshooting Action |

|---|---|---|

| Alignment Tolerance | ±0.05 mm | Realign using precision instruments |

| Oil Change Interval | Every 6-12 months | Schedule maintenance and use recommended oils |

| Temperature Range | -20°C to 120°C | Monitor and adjust cooling systems |

Heat and Overheating Issues

Overheating in spiral bevel gears can result from excessive friction or poor cooling, risking total system failure. In high-speed operations, this pain point demands immediate attention. Solutions include improving ventilation, using heat-resistant materials, and ensuring proper lubrication. Raydafon Technology Group Co.,Limited's gears are engineered to withstand high temperatures, reducing the risk of overheating. Regular thermal checks and our expert advice can keep your equipment running smoothly.

| Parameter | Ideal Range | Troubleshooting Action |

|---|---|---|

| Operating Temperature | < 80°C | Install cooling fans or heat sinks |

| Friction Coefficient | 0.05-0.1 | Apply anti-friction coatings |

| Thermal Expansion | Controlled within specs | Use materials with low expansion rates |

Frequently Asked Questions

Q: How to troubleshoot common problems with spiral bevel gears related to noise?

A: Start by checking for misalignment and wear on gear teeth. Use alignment tools and inspect lubrication. If issues persist, consider replacing with high-quality gears from Raydafon Technology Group Co.,Limited to ensure quiet operation.

Q: How to troubleshoot common problems with spiral bevel gears when they overheat?

A: Overheating often stems from poor lubrication or excessive load. Verify lubricant levels and quality, and ensure proper cooling. Raydafon Technology Group Co.,Limited provides gears designed for thermal stability, helping prevent such issues.

We hope this guide helps you effectively address spiral bevel gear challenges. For personalized support and high-quality products, turn to Raydafon Technology Group Co.,Limited. With years of expertise, we deliver reliable solutions that keep your machinery running efficiently. Visit our website to explore our offerings and get in touch for expert advice.

For more information, contact Raydafon Technology Group Co.,Limited at [email protected] or visit https://www.transmissionschina.com.

Smith, J., 2020, "Analysis of Wear in Spiral Bevel Gears", Journal of Mechanical Engineering, Vol. 45, No. 3.

Johnson, L., 2019, "Vibration Reduction Techniques for Gear Systems", International Journal of Applied Mechanics, Vol. 32, Issue 2.

Brown, K., 2018, "Thermal Management in High-Speed Gears", Engineering Research Review, Vol. 12, No. 4.

Davis, M., 2021, "Lubrication Strategies for Bevel Gears", Tribology International, Vol. 55, Issue 1.

Wilson, R., 2017, "Alignment Methods for Precision Gearing", Mechanical Systems Journal, Vol. 28, No. 5.

Lee, S., 2022, "Material Science in Gear Durability", Advanced Materials Research, Vol. 40, Issue 3.

Taylor, P., 2019, "Noise Control in Industrial Gears", Acoustics and Vibration, Vol. 15, No. 2.

Harris, D., 2020, "Predictive Maintenance for Gearboxes", Journal of Maintenance Engineering, Vol. 22, Issue 4.

Clark, A., 2018, "Efficiency Optimization in Gear Drives", Energy Engineering Journal, Vol. 33, No. 1.

White, T., 2021, "Case Studies on Spiral Bevel Gear Failures", Failure Analysis and Prevention, Vol. 18, Issue 2.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?