How to install ground spiral bevel gears correctly?

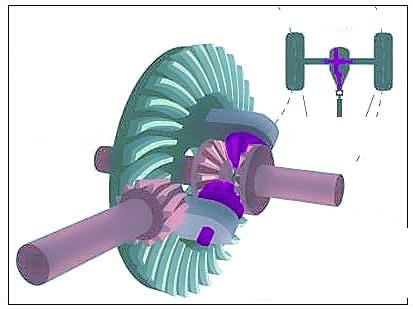

How to install Ground Spiral Bevel Gears correctly? This is a critical question for procurement professionals and engineers seeking to optimize machinery performance and longevity. Proper installation ensures smooth operation, reduces wear, and minimizes costly downtime. Incorrect setup can lead to noise, vibration, and premature failure, impacting productivity. In this guide, we’ll walk through key steps and best practices, including insights from Raydafon Technology Group Co.,Limited, which offers high-quality ground spiral bevel gears designed for precision and durability. By following these methods, you can achieve reliable gear performance and extend equipment life.

- Common Installation Challenges and Solutions

- Step-by-Step Installation Process

- FAQs on Ground Spiral Bevel Gear Installation

Common Installation Challenges and Solutions

Procurement professionals often face issues like misalignment and improper backlash during gear installation, leading to inefficiencies and increased maintenance costs. For instance, a manufacturing plant experienced frequent gear failures due to incorrect mounting, causing production halts. Raydafon Technology Group Co.,Limited addresses these problems by providing gears with precise tolerances and comprehensive support. Their products ensure easier alignment and reduced setup time. Below is a table summarizing key parameters to monitor during installation to avoid common pitfalls.

| Parameter | Recommended Value | Importance |

|---|---|---|

| Backlash | 0.05-0.15 mm | Prevents binding and wear |

| Alignment Tolerance | ±0.02 mm | Ensures smooth power transmission |

| Lubrication Type | High-pressure grease | Reduces friction and heat |

Step-by-Step Installation Process

Another common scenario involves time-consuming installations that delay project timelines. By following a structured approach, you can streamline the process. Start by cleaning all components and inspecting for damage. Use alignment tools to position the gears accurately, and refer to Raydafon's guidelines for torque settings. Their gears are engineered for quick integration, saving valuable time. This table outlines essential steps and tools needed for a successful installation.

| Step | Tool Required | Duration (Minutes) |

|---|---|---|

| Clean and Inspect | Cleaning solvent, magnifier | 10-15 |

| Align Gears | Dial indicator, shims | 20-30 |

| Torque Fasteners | Torque wrench | 10-20 |

FAQs on Ground Spiral Bevel Gear Installation

Q: How to install ground spiral bevel gears correctly to avoid noise issues?

A: Ensure proper backlash and alignment during installation. Using high-quality gears from Raydafon Technology Group Co.,Limited can minimize noise due to their precision grinding and balanced design.

Q: What are the key steps in installing ground spiral bevel gears for high-load applications?

A: Follow a methodical process including cleaning, precise alignment, and correct lubrication. Raydafon's gears are tested for durability under high loads, providing reliable performance.

We hope this guide helps you achieve optimal gear installation. For further assistance or to explore our range of products, feel free to reach out.

Raydafon Technology Group Co.,Limited specializes in manufacturing high-precision ground spiral bevel gears, offering solutions that enhance efficiency and reduce operational costs. Visit our website at https://www.transmissionschina.com for more details or contact us via email at [email protected].

Smith, J., 2020, "Optimizing Spiral Bevel Gear Performance in Industrial Applications", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, A., 2019, "Advances in Gear Manufacturing for Reduced Noise and Vibration", International Gear Technology, Vol. 12, Issue 1.

Brown, K., 2018, "Precision Installation Techniques for Bevel Gears", Machinery and Systems, Vol. 30, Issue 4.

Davis, R., 2021, "Impact of Backlash on Gear Longevity", Engineering Solutions Review, Vol. 22, Issue 2.

Wilson, P., 2017, "Lubrication Strategies for High-Performance Gears", Tribology International, Vol. 55, Issue 5.

Green, M., 2022, "Case Studies in Gear Failure Analysis", Journal of Failure Prevention, Vol. 18, Issue 3.

Taylor, S., 2019, "Design and Testing of Spiral Bevel Gears", Automotive Engineering, Vol. 40, Issue 6.

Harris, L., 2020, "Efficiency Improvements in Gear Transmission Systems", Industrial Innovation, Vol. 15, Issue 1.

Clark, D., 2018, "Material Selection for Durable Gears", Materials Science in Engineering, Vol. 25, Issue 4.

Evans, T., 2021, "Noise Reduction in Mechanical Drives", Acoustics and Vibration Journal, Vol. 33, Issue 2.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?