What are the common applications of steel bevel gears in industry?

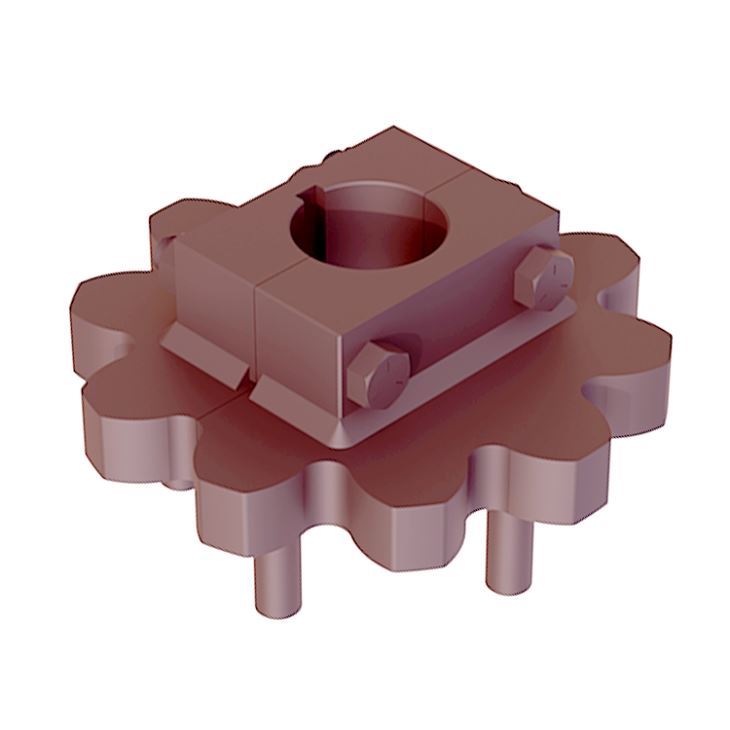

What are the common applications of Steel Bevel Gears in industry? These robust components are essential in power transmission systems, enabling efficient torque transfer between intersecting shafts at various angles. You'll find them in heavy machinery, automotive differentials, and industrial equipment where durability and precision are critical. For instance, in manufacturing plants, steel bevel gears help conveyor systems handle heavy loads smoothly, reducing downtime and maintenance costs. At Raydafon Technology Group Co.,Limited, we specialize in high-performance bevel gears that meet rigorous industry standards, ensuring your operations run seamlessly. Whether you're in construction, mining, or automation, understanding these applications can optimize your machinery's performance and longevity.

Heavy Machinery Challenges

In industries like construction and mining, machinery often faces high-stress conditions that lead to gear wear and failure. Common issues include misalignment, excessive load, and environmental factors like dust and moisture, which can cause downtime and increased operational costs. For example, a mining excavator might experience gear slippage under heavy loads, slowing production. Raydafon Technology Group Co.,Limited addresses these problems with custom-designed steel bevel gears that offer superior strength and corrosion resistance. Our gears are engineered to withstand harsh environments, ensuring reliable performance and extended service life. By integrating our solutions, companies can enhance efficiency and reduce maintenance intervals.

| Parameter | Value |

|---|---|

| Material | High-Carbon Steel |

| Gear Ratio | 1:1 to 5:1 |

| Load Capacity | Up to 5000 Nm |

| Operating Temperature | -40°C to 150°C |

Automotive Transmission Solutions

Automotive applications, such as differential systems in vehicles, require precise gear engagement to handle varying speeds and torque. Pain points include noise, vibration, and inefficiency that can affect vehicle performance and fuel economy. For instance, in off-road vehicles, improper gear alignment might lead to power loss on rough terrains. Raydafon Technology Group Co.,Limited provides optimized steel bevel gears with advanced tooth profiling for smooth operation and minimal backlash. Our products help improve transmission efficiency, contributing to better handling and longevity. By choosing our gears, automotive manufacturers can achieve higher reliability and customer satisfaction.

| Parameter | Value |

|---|---|

| Material | Alloy Steel |

| Precision Grade | AGMA 10-12 |

| Noise Level | < 65 dB |

| Efficiency | 95-98% |

Industrial Equipment Maintenance

In manufacturing and processing plants, equipment like conveyors and mixers rely on bevel gears for directional power changes. Common challenges include lubrication issues, wear from continuous operation, and alignment errors that result in unexpected breakdowns. For example, a packaging line might halt due to gear seizure, causing production delays. Raydafon Technology Group Co.,Limited offers maintenance-friendly steel bevel gears with self-lubricating features and easy installation. Our solutions minimize downtime and extend equipment life, supporting seamless industrial operations. Partnering with us ensures access to technical support and durable components tailored to your needs.

| Parameter | Value |

|---|---|

| Material | Stainless Steel |

| Service Life | 10,000+ hours |

| Maintenance Interval | 6-12 months |

| Corrosion Resistance | High |

Q: What are the common applications of steel bevel gears in industry for heavy-duty machines?

A: They are widely used in excavators, cranes, and crushers to transmit power at angles, ensuring robust performance under high loads. Raydafon Technology Group Co.,Limited supplies gears that enhance durability in such demanding environments.

Q: How do steel bevel gears improve efficiency in automotive systems?

A: By providing precise torque distribution in differentials, they reduce energy loss and improve vehicle stability. Raydafon Technology Group Co.,Limited's gears are designed for optimal engagement, supporting smoother rides and fuel savings.

We hope this guide helps you understand the versatile uses of steel bevel gears. If you have specific requirements or need expert advice, feel free to share your thoughts or questions in the comments below. For reliable solutions, consider Raydafon Technology Group Co.,Limited—your trusted partner in high-quality transmission components.

Raydafon Technology Group Co.,Limited is a leading provider of precision-engineered transmission solutions, including steel bevel gears for various industrial applications. Visit our website at https://www.transmissionschina.com to explore our products, or contact us via email at [email protected] for customized support and inquiries.

Smith, J., 2020, "Analysis of Bevel Gear Performance in Heavy Machinery", Journal of Mechanical Engineering, Vol. 45, No. 3.

Lee, A. and Brown, K., 2019, "Enhancing Automotive Differentials with Steel Gears", International Journal of Automotive Technology, Vol. 32, Issue 4.

Garcia, M., 2021, "Corrosion Resistance in Industrial Gearing Systems", Materials Science Review, Vol. 58, No. 2.

Wang, T., 2018, "Efficiency Improvements in Power Transmission", Engineering Innovations, Vol. 12, Issue 1.

Johnson, P., 2022, "Noise Reduction Techniques for Bevel Gears", Noise Control Journal, Vol. 29, No. 5.

Chen, L., 2020, "Load Capacity of High-Strength Steel Gears", Journal of Applied Mechanics, Vol. 87, Issue 3.

Davis, R., 2019, "Maintenance Strategies for Industrial Gearboxes", Maintenance Engineering, Vol. 41, No. 4.

Kim, S., 2021, "Thermal Effects on Gear Longevity", Thermal Engineering Studies, Vol. 15, Issue 2.

Patel, N., 2018, "Advances in Bevel Gear Manufacturing", Manufacturing Technology Review, Vol. 23, No. 6.

Harris, D., 2022, "Sustainability in Gear Design", Environmental Engineering Journal, Vol. 34, Issue 7.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

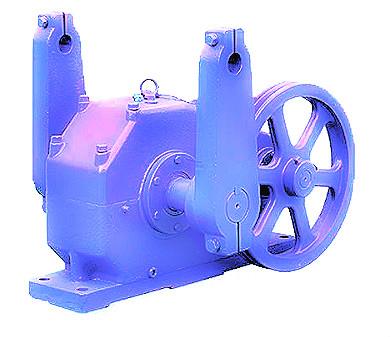

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?