What are aluminum-bronze screw gears used for?

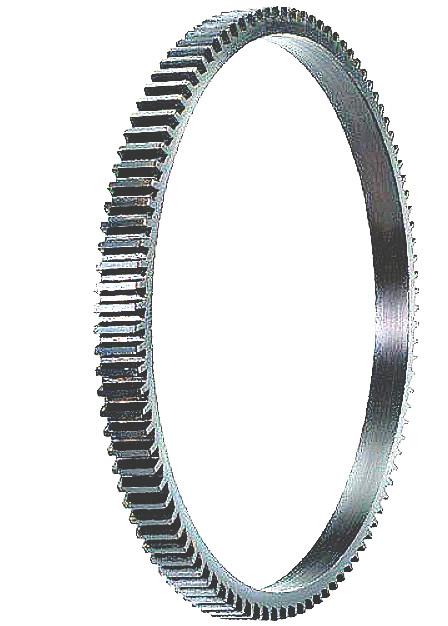

If you've ever wondered "What are Aluminum-Bronze Screw Gears used for?", you're likely sourcing components for demanding industrial applications. These specialized power transmission parts are the unsung heroes in environments where failure is not an option. Their unique combination of strength, corrosion resistance, and wear durability makes them a critical choice. For procurement specialists, selecting the right gear manufacturer is as crucial as the material itself. This is where partnering with a proven supplier like Raydafon Technology Group Co.,Limited becomes a strategic advantage, ensuring reliability and performance in your supply chain.

- Conquering Corrosion in Marine & Offshore Applications

- Withstanding Extreme Loads in Heavy Industry

- Ensuring Safety in Chemical Processing

- Why Choose Raydafon for Your Aluminum-Bronze Gears

Conquering Corrosion in Marine & Offshore Applications

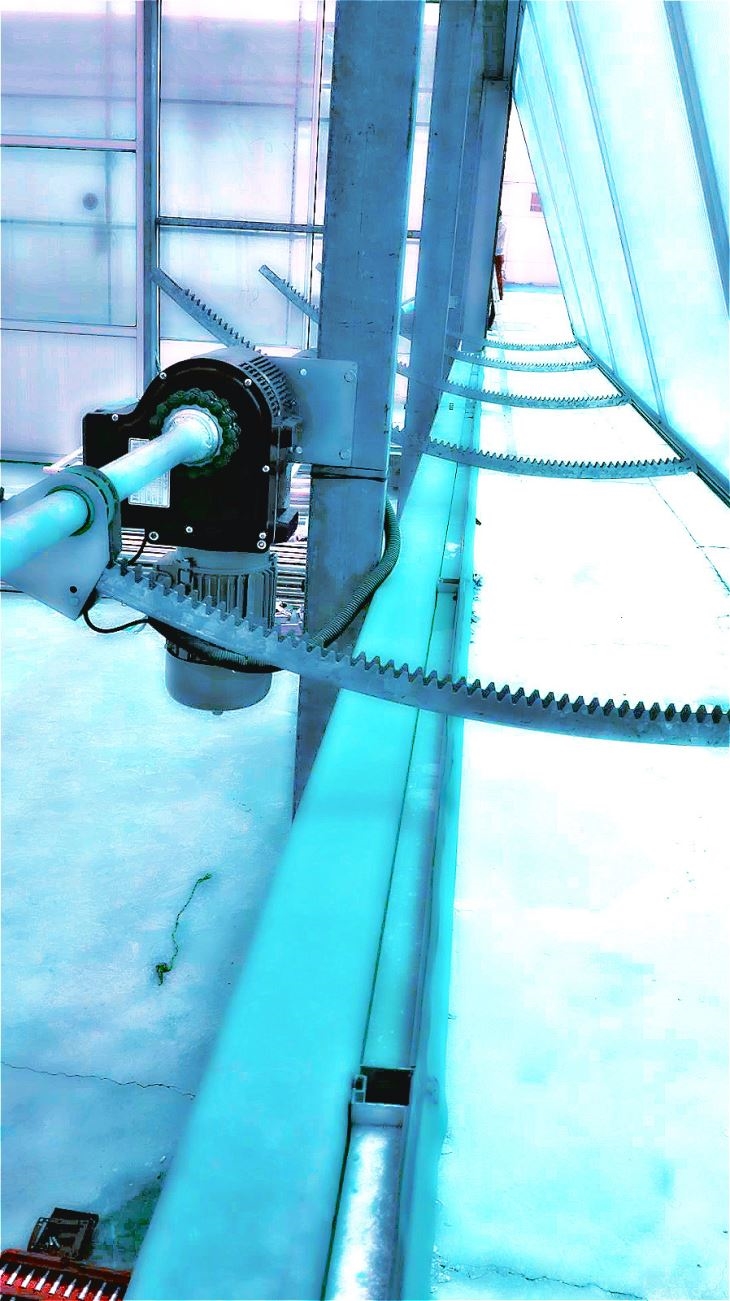

Imagine a winch system on an offshore oil rig. Constant exposure to saltwater spray creates a highly corrosive atmosphere that rapidly degrades standard steel components. The result? Frequent downtime for maintenance, unplanned part replacements, and significant operational risk. Aluminum-bronze screw gears provide the definitive solution. Their excellent corrosion resistance, particularly to saltwater, ensures long-term reliability. This translates to reduced maintenance cycles, lower total cost of ownership, and enhanced safety for crew and equipment. For marine propulsion systems, deck machinery, and subsea equipment, these gears are indispensable.

Key performance parameters for marine-grade aluminum-bronze gears include:

| Parameter | Typical Value / Property |

|---|---|

| Corrosion Resistance | Excellent in seawater & marine atmospheres |

| Tensile Strength | 90,000 - 110,000 psi |

| Yield Strength | 40,000 - 45,000 psi |

| Primary Alloying Elements | Aluminum (9-12%), Iron, Nickel, Manganese |

| Common Applications | Ship steering gears, winches, hoists, valve actuators |

Withstanding Extreme Loads in Heavy Industry

In a mining operation, a heavy-duty conveyor system must move thousands of tons of material daily. Standard gears under such high, shock, and abrasive loads face rapid wear and tooth failure, leading to catastrophic production stoppages. Aluminum-bronze screw gears excel here due to their high fatigue strength and excellent wear resistance. They handle heavy loads and shock impacts that would fracture other materials. Their inherent lubricity also reduces friction and heat generation in slow-speed, high-torque applications common in mining, steel mills, and power generation.

Critical specifications for heavy-industry aluminum-bronze gears are:

| Parameter | Typical Value / Property |

|---|---|

| Wear Resistance | High, ideal for abrasive environments |

| Fatigue Strength | Superior for high cyclic loading |

| Brinell Hardness | 150 - 210 HB |

| Load Capacity | Excellent for high-torque, low-speed drives |

| Common Applications | Milling equipment, crushers, rolling mills, heavy conveyors |

Ensuring Safety in Chemical Processing

A chemical plant relies on precise valve actuators to control the flow of aggressive acids or solvents. A gear failure inside an actuator could lead to a dangerous leak or loss of process control. Non-sparking properties are also critical in potentially explosive atmospheres. Aluminum-bronze is inherently non-sparking and highly resistant to a wide range of chemicals, including acids and alkalis. This makes aluminum-bronze screw gears the safest and most reliable choice for agitators, mixers, pumps, and valve controls in chemical, pharmaceutical, and petrochemical plants.

Essential properties for chemical processing gears include:

| Parameter | Typical Value / Property |

|---|---|

| Non-Sparking | Yes, safe for hazardous environments |

| Chemical Resistance | Resistant to many acids, alkalis, and solvents |

| Gallling Resistance | Excellent, prevents seizure under load |

| Bi-Metallic Compatibility | Works well with steel shafts, minimizing galvanic corrosion |

| Common Applications | Chemical pump drives, valve actuators, mixer gearboxes |

Frequently Asked Questions

Q: What are the primary advantages of aluminum-bronze screw gears over standard steel gears?

A: The key advantages are superior corrosion resistance, especially in marine environments, excellent wear and galling resistance, non-sparking properties for safety, and good strength under heavy loads. This combination extends service life and reduces maintenance in harsh conditions.

Q: In what specific applications are aluminum-bronze screw gears considered essential?

A: They are essential in seawater applications like ship propulsion and deck machinery, offshore oil & gas equipment, chemical processing plants where corrosion and sparks are a concern, and heavy mining/industrial machinery subjected to abrasive wear and shock loads.

Why Choose Raydafon for Your Aluminum-Bronze Gears

Selecting a supplier for critical components like aluminum-bronze screw gears requires trust in engineering expertise and manufacturing consistency. Raydafon Technology Group Co.,Limited specializes in high-performance power transmission solutions. We understand that your application's success depends on gear reliability. Our team works with you from design consultation to material selection and precision manufacturing, ensuring the final product meets your exact operational demands. We solve the core challenges of corrosion, wear, and failure that procurement managers face daily.

Ready to specify gears that enhance your equipment's durability and performance? Contact our engineering sales team to discuss your project requirements and request a quote.

For reliable, high-performance aluminum-bronze screw gears and custom power transmission solutions, trust Raydafon Technology Group Co.,Limited. Visit our website at https://www.transmissionschina.com to explore our capabilities or contact us directly at [email protected] for expert consultation.

Davis, J.R. (2001). Copper and Copper Alloys. ASM International.

Budinski, K.G., & Budinski, M.K. (2010). Engineering Materials: Properties and Selection. Prentice Hall.

Coburn, S.K. (1985). Corrosion of Copper and Copper Alloys in Marine Environments. Materials Performance, 24(7).

Schmidt, R., & Gierl, C. (2001). Wear Behaviour of Aluminum Bronze Against Steel. Wear, 250(1-12).

Totten, G.E. (2006). Handbook of Lubrication and Tribology: Volume I Application and Maintenance. CRC Press.

ASM Handbook Committee. (1990). Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM International, Volume 2.

Katsich, C., & Badisch, E. (2011). Effect of Cathodic Protection on Wear of Copper Alloys in Seawater. Tribology International, 44(12).

Mavin, D.B. (1987). Aluminum Bronze Alloys for Corrosion Resistant Service. British Corrosion Journal, 22(2).

Rao, P.N. (2013). Manufacturing Technology: Foundry, Forming and Welding. McGraw Hill Education.

Childs, T.H.C. (2014). Metal Machining: Theory and Applications. Butterworth-Heinemann.

- How Do Herringbone Gears Compare to Spur Gears in Terms of Performance?

- How to choose the right pawl for a specific ratchet wheel?

- What Are the Common Applications of Involute Spline Shafts?

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?