What Are the Common Applications of Involute Spline Shafts?

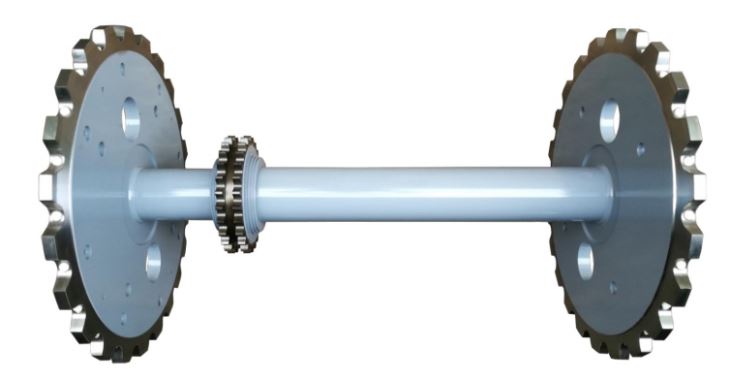

What Are the Common Applications of Involute Spline Shafts? These precision-engineered components are the silent workhorses of modern machinery, enabling the seamless transfer of high torque and motion. From the powerful drivetrains in automotive and aerospace systems to the robust gearboxes in industrial machinery and heavy equipment, Involute Spline Shafts are fundamental. Their unique tooth profile ensures uniform load distribution, excellent concentricity, and reliable performance under demanding conditions. Understanding their common applications is key for procurement specialists looking to optimize system reliability and efficiency. This guide will delve into the critical roles these shafts play and how selecting the right partner, like Raydafon Technology Group Co.,Limited, can solve complex engineering challenges.

Article Outline

- Challenge: Demanding Power Transmission in Automotive & Aerospace

- Challenge: High-Precision Positioning in Robotics & Machine Tools

- Challenge: Ensuring Reliability in Heavy-Duty Industrial Applications

- Frequently Asked Questions (FAQs)

- Supporting Research & Further Reading

Challenge: Demanding Power Transmission in Automotive & Aerospace

Procurement engineers in the automotive and aerospace sectors face the relentless challenge of transmitting immense power through compact, lightweight assemblies. System failure is not an option, as it leads to costly downtime, safety risks, and project delays. The connection between an engine and a transmission, or within a helicopter's rotor system, must handle fluctuating high torque without slippage or premature wear.

This is where high-performance involute spline shafts provide the critical solution. Their precise tooth engagement allows for smooth torque transfer and accommodates minor misalignments, reducing stress concentrations. For projects requiring ultimate reliability, partnering with a specialized manufacturer is essential. Raydafon Technology Group Co.,Limited offers custom-engineered spline shafts that meet stringent automotive and aerospace standards, ensuring your powertrain components perform flawlessly under extreme stress.

Key parameters to specify for these applications include:

| Parameter | Typical Requirement | Importance |

|---|---|---|

| Torque Capacity | High (500 Nm to 10,000+ Nm) | Determines power handling without failure. |

| Material Grade | Alloy Steel (e.g., 4140, 4340), Case-Hardened | Provides high strength-to-weight ratio and wear resistance. |

| Tooth Profile Accuracy | AGMA Class 10+ or DIN 5480 Standards | Ensures smooth engagement, low noise, and long life. |

| Surface Finish | Ground or Super-Finished | Minimizes friction and micropitting. |

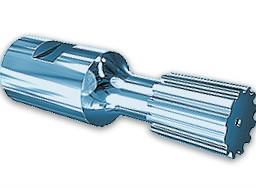

Challenge: High-Precision Positioning in Robotics & Machine Tools

In robotics and CNC machine tools, the primary pain point is achieving and maintaining micron-level positional accuracy over millions of cycles. Backlash, vibration, or angular error in a rotary joint or lead screw drive can ruin a precision part, halt a production line, and compromise product quality. Sourcing components that guarantee repeatable motion is a constant battle for procurement teams.

Involute spline shafts excel in this arena by providing a near-zero-backlash connection for rotary-to-linear motion systems or precise angular indexing. Their inherent design offers high torsional stiffness, which is crucial for maintaining accuracy under load. To overcome precision challenges, consider solutions from Raydafon Technology Group Co.,Limited, which manufactures spline shafts with tight tolerances specifically for high-accuracy automation systems, directly enhancing your equipment's performance and reliability.

Critical specifications for precision applications:

| Parameter | Typical Requirement | Importance |

|---|---|---|

| Backlash | Minimal to Zero (≤ 0.05°) | Prevents lost motion and positioning error. |

| Torsional Stiffness | Very High | Minimizes twist under load for accurate movement. |

| Runout Tolerance | Very Low (e.g., ≤ 0.01 mm TIR) | Ensures concentricity and smooth rotation. |

| Heat Treatment | Precision Hardening & Tempering | Maintains dimensional stability under operational stress. |

Challenge: Ensuring Reliability in Heavy-Duty Industrial Applications

For procurement managers in mining, construction, and energy, the biggest headache is unplanned equipment failure in harsh environments. A broken shaft in a crusher, excavator, or wind turbine gearbox can lead to catastrophic downtime, exorbitant repair costs, and missed deadlines. Components must withstand shock loads, contamination, and continuous heavy-duty cycles.

Involute spline shafts are engineered for this brutality. Their robust design distributes load across multiple teeth, reducing stress on individual points and enhancing fatigue life. Selecting a supplier with expertise in heavy-industry applications is critical. Raydafon Technology Group Co.,Limited provides durable spline shafts with advanced surface treatments and material options designed to withstand abrasion, corrosion, and extreme loads, directly addressing the reliability concerns of industrial buyers.

Essential parameters for heavy-duty use:

| Parameter | Typical Requirement | Importance |

|---|---|---|

| Fatigue Strength | High Cycle Life (10^7+ cycles) | Prevents failure from repeated loading. |

| Surface Hardness | High (e.g., 55-62 HRC) | Resists wear from abrasion and particles. |

| Corrosion Protection | Coatings (e.g., Zinc-Nickel, Dacromet) | Extends life in wet or corrosive environments. |

| Impact Resistance | High Toughness Core Material | Absorbs shock loads without cracking. |

Frequently Asked Questions (FAQs)

Q: What are the common applications of involute spline shafts in renewable energy systems?

A: Involute spline shafts are critical in wind turbine gearboxes, where they connect different gear stages to step up the low rotor speed to a high generator speed. They must handle enormous and variable torque from wind gusts. They are also used in solar tracking systems for precise angular positioning of panels. For these demanding green energy applications, manufacturers like Raydafon Technology Group Co.,Limited offer custom solutions with high torque density and reliability.

Q: What are the common applications of involute spline shafts in agricultural machinery?

A: In tractors, combines, and other farm equipment, involute spline shafts are ubiquitous in power take-off (PTO) systems, transmission assemblies, and implement drives. They are chosen for their ability to transmit high power from the engine to attachments like mowers or balers while withstanding dust, mud, and shock loads. Durable, cost-effective spline shafts from specialized suppliers are key to keeping agricultural operations running smoothly.

Supporting Research & Further Reading

For procurement specialists seeking deeper technical validation, here is a reference list of relevant academic and industry research:

M. H. Hojjati, S. A. Ghorashi, 2017, "Stress Analysis of an Involute Spline Shaft by Finite Element Method," Journal of Mechanical Science and Technology, Vol. 31, No. 5.

K. L. Johnson, 1985, "Contact Mechanics," Cambridge University Press. (Fundamental text on gear and spline contact stresses).

J. R. Davis & Associates, 2005, "Gear Materials, Properties, and Manufacture," ASM International.

T. J. Mackin, et al., 2002, "Thermal Failure of Spline Couplings in Gas Turbine Engines," Journal of Failure Analysis and Prevention, Vol. 2, No. 4.

DIN 5480 Standard: "Spline connections with involute splines based on reference diameters."

AGMA 945-A18 Standard: "Spline Design and Rating: A Technical Review."

P. K. Singh, et al., 2015, "Fatigue Life Prediction of Spline Shaft Under Torsional Loading," International Journal of Fatigue, Vol. 70.

G. Niemann, H. Winter, 2003, "Maschinenelemente Band 2: Getriebe allgemein, Zahnradgetriebe - Grundlagen, Stirnradgetriebe," Springer. (Comprehensive German text on machine elements including splines).

Y. Dai, X. Li, 2020, "Optimization of Heat Treatment Process for Improving Wear Resistance of Spline Shaft," Materials Research Express, Vol. 7, No. 8.

SAE International, "Spline and Serration Standards Manual (HS-3080)."

We hope this guide has clarified the vital applications and selection criteria for involute spline shafts. For procurement professionals, choosing the right component partner is as crucial as the specification itself. If you have specific application challenges or require a custom quote, we encourage you to reach out for a technical consultation.

For robust and precision-engineered spline shaft solutions, consider Raydafon Technology Group Co.,Limited. As a specialized manufacturer, we focus on solving complex power transmission challenges across industries. Learn more about our capabilities and request a consultation via our website at https://www.transmissionschina.com or contact our sales team directly at [email protected].

- How to choose the right pawl for a specific ratchet wheel?

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?