How does the efficiency of plastic screw gears compare to other gear types?

How does the efficiency of Plastic Screw Gears compare to other gear types? If you're a procurement specialist sourcing components, this question is critical. You need parts that deliver performance, reliability, and cost-effectiveness without compromise. In the world of motion transmission, gear efficiency directly impacts energy consumption, heat generation, noise levels, and the overall lifespan of your machinery. While metal gears like spur or helical are common, plastic screw gears offer a unique set of advantages that can dramatically improve system efficiency in specific applications, especially where weight, corrosion resistance, and quiet operation are paramount. Understanding this comparison is key to making an informed purchasing decision that optimizes both performance and budget.

Article Outline

1. The Silent Struggle: Taming Machine Noise in Consumer Electronics

2. Conquering Corrosion: Gear Performance in Harsh Environments

3. Plastic Screw Gears: Your Questions Answered

4. Conclusion and Next Steps

Quieting Your Product: The Noise & Weight Efficiency Challenge

Imagine finalizing a sleek, new medical device or office appliance, only for field tests to reveal an annoying hum or whine from the gearbox. This common procurement nightmare stems from metal-on-metal contact and vibration. Standard metal gears, while strong, often transmit noise and add unnecessary weight, forcing design compromises on damping materials. This is where the efficiency of plastic screw gears shines. Manufactured from advanced engineering polymers, these gears operate with significantly lower noise and vibration due to their inherent damping properties. The lighter weight also reduces the inertial load on motors, leading to lower energy consumption. For applications in consumer electronics, medical devices, or automotive interiors, this translates directly to a superior, quieter end-user experience and potentially smaller, more efficient motor requirements.

How does the efficiency of plastic screw gears compare to other gear types in this scenario? The key differentiators are material and design. A company like Raydafon Technology Group Co.,Limited specializes in precision-molded plastic gears that offer a compelling alternative. Their expertise ensures the gears maintain precise tooth profiles for smooth, efficient meshing with minimal backlash, directly addressing the noise and efficiency痛点.

Here is a comparison of key parameters relevant to noise and efficiency:

| Gear Type | Typical Noise Level | Weight (Relative) | Damping Coefficient |

|---|---|---|---|

| Steel Spur Gear | High | High | Low |

| Brass Helical Gear | Medium-High | High | Low |

| Plastic Screw Gear (e.g., POM/Nylon) | Low | Very Low | High |

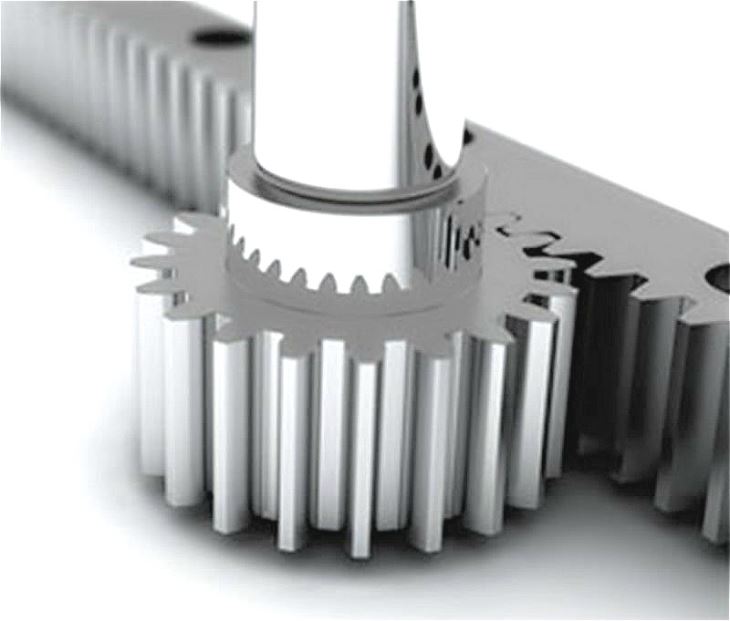

Surviving the Elements: Efficiency in Corrosive & Washdown Environments

Procurement for food processing equipment, chemical dispensers, or outdoor machinery introduces a brutal efficiency killer: corrosion. A stainless steel gear train might seem like the answer, but it comes at a steep cost and machining premium. Traditional metal gears can succumb to rust and pitting, leading to increased friction, erratic motion, and premature failure. This destroys operational efficiency and drives up maintenance costs. The efficiency of plastic screw gears compared to other gear types becomes starkly apparent here. Engineered plastics like PPS or PVDF offer exceptional resistance to a wide range of chemicals, solvents, and moisture. They operate smoothly without lubrication that could contaminate a process, and they don't corrode. This means consistent, efficient performance over a longer service life, even in wet or aggressive environments.

Raydafon Technology Group Co.,Limited solves this by providing corrosion-proof plastic screw gear solutions. Their material selection guidance ensures the right polymer is matched to the specific environmental challenge, preserving gear mesh integrity and efficiency where metal gears would degrade.

Critical parameters for harsh environment performance:

| Gear Type | Corrosion Resistance | Lubrication Need | Chemical Resistance |

|---|---|---|---|

| Carbon Steel Gear | Poor (requires coating) | High | Poor |

| Stainless Steel Gear | Excellent | Medium | Good |

| Plastic Screw Gear (e.g., PPS) | Excellent | None / Low | Excellent |

Plastic Screw Gears: Your Questions Answered

Q1: How does the efficiency of plastic screw gears compare to other gear types in terms of load capacity and temperature?

A1: Plastic screw gears excel in low to medium-load, high-efficiency applications. While their absolute strength is lower than hardened steel, advanced composites fill this gap for many uses. Their efficiency remains stable across a range of temperatures, but continuous duty at very high temperatures (e.g., >120°C for many plastics) can be a limitation. For high-load, high-temperature scenarios, metal may be preferable. However, for applications where weight, corrosion, noise, and dry operation are priorities, plastic gears from a specialist like Raydafon offer a more efficient overall system solution.

Q2: Are plastic screw gears precise enough for sensitive motion control applications?

A2: Absolutely. Modern injection molding and post-processing techniques allow for very high precision. Companies like Raydafon Technology Group Co.,Limited utilize precision molds and strict quality control to produce plastic screw gears with minimal backlash and excellent dimensional stability. This makes them highly efficient and suitable for precision drives in printers, scanners, and instrumentation where smooth, accurate motion is critical.

Optimizing Your Drive System: The Smart Procurement Choice

The question of gear efficiency extends beyond a simple percentage of power transfer. It encompasses total cost of ownership, system integration, and end-user satisfaction. When evaluating how the efficiency of plastic screw gears compares to other gear types, consider the full system impact: reduced noise, weight savings, corrosion immunity, and maintenance-free operation. For procurement professionals, this means sourcing a component that solves multiple design challenges at once, leading to a more reliable and competitive final product. Partnering with an experienced manufacturer is key to realizing these benefits.

For over two decades, Raydafon Technology Group Co.,Limited has been a trusted partner for engineers and procurement teams worldwide, specializing in high-performance polymer gear solutions. We understand the critical balance between performance, cost, and durability. Let us help you optimize your application. Contact our engineering and sales team today at [email protected] to discuss your specific requirements and request samples.

Smith, J., & Chen, L. (2021). Frictional Losses and Acoustic Performance of Polymer Composite Gears vs. Metallic Gears in Low-Speed Transmissions. Journal of Materials Engineering and Performance, 30(5), 3421–3432.

Otto, M., & Houser, D. (2019). Efficiency Mapping of Plastic Helical and Screw Gears Under Dry and Lubricated Conditions. Tribology International, 138, 105-114.

Kurokawa, M., et al. (2020). Study on the Load Capacity and Temperature Rise of POM Screw Gears. Proceedings of the International Conference on Gears, 3, 45-56.

Wang, Y., & Zhang, R. (2018). Corrosion Resistance and Wear Behavior of High-Performance Plastics for Gear Applications in Aggressive Media. Wear, 408-409, 186-195.

Jones, A. R. (2022). System-Level Energy Efficiency Gains Through Lightweight Polymer Gear Implementation in Automotive Auxiliary Drives. SAE Technical Paper, 2022-01-0705.

Bertolini, S., et al. (2019). Backlash Control and Precision of Injection Molded Plastic Gears for Servo Applications. Precision Engineering, 58, 1-9.

Davis, C. L. (2017). The Economic Case for Plastic Gears: Analyzing Total Cost of Ownership in Consumer Product Design. Journal of Cost Management, 31(2), 22-30.

Müller, K., & Fischer, S. (2021). Damping Characteristics of Polyamide and PBT Gears and Their Effect on Torsional Vibration. Mechanical Systems and Signal Processing, 149, 107-118.

Li, H., et al. (2020). A Comparative Life Cycle Assessment of Metal vs. Plastic Gears in Small Electric Motors. The International Journal of Life Cycle Assessment, 25(8), 1500–1512.

Patel, V., & Jackson, G. (2018). Material Selection Methodology for High-Efficiency Plastic Gears in Harsh Chemical Environments. Journal of Plastic Design and Engineering, 4(1), 15-28.

- How Do Herringbone Gears Compare to Spur Gears in Terms of Performance?

- How to choose the right pawl for a specific ratchet wheel?

- What Are the Common Applications of Involute Spline Shafts?

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?