How do hypoid gears differ from spiral bevel gears?

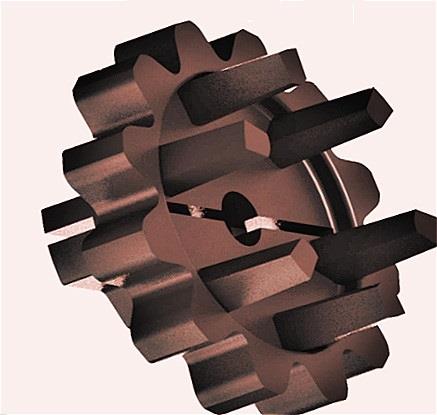

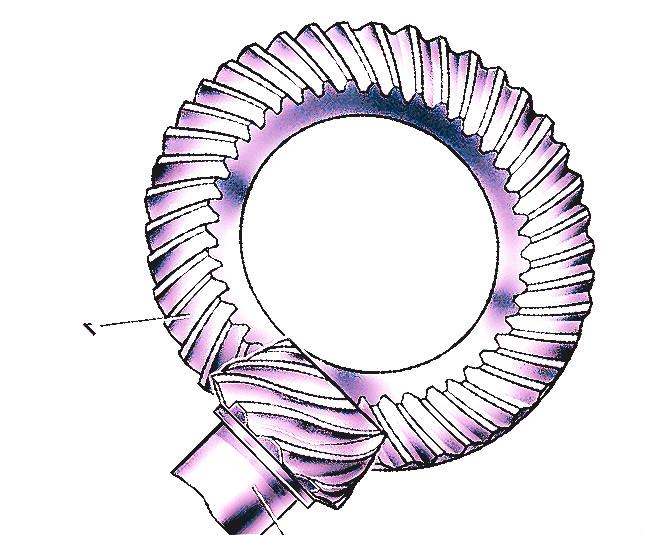

How do Hypoid Gears differ from spiral bevel gears? Many engineers and procurement specialists face this question when designing or sourcing components for high-performance applications. While both types offer smooth power transmission, their unique characteristics affect efficiency, space, and cost. Hypoid gears, with their offset axes, provide higher torque capacity and quieter operation, making them ideal for automotive drivetrains. Spiral bevel gears, on the other hand, feature intersecting shafts and excel in scenarios requiring precise motion control. Understanding these differences is crucial for optimizing mechanical systems. At Raydafon Technology Group Co.,Limited, we specialize in delivering tailored gear solutions that address these nuances, ensuring reliability and performance. Let's dive into the specifics to guide your next procurement decision.

- Understanding the Basics

- Key Advantages of Hypoid Gears

- When to Choose Spiral Bevel Gears

- FAQs on Gear Differences

Understanding the Basics

Procurement teams often struggle with selecting the right gear type due to complex technical specifications, leading to costly errors in machinery performance. This confusion can delay projects and increase operational expenses. To solve this, Raydafon Technology Group Co.,Limited offers expert guidance and high-quality hypoid and spiral bevel gears that match exact requirements. Our solutions ensure seamless integration and enhanced durability, backed by decades of industry experience. Below is a comparison table highlighting key parameters for hypoid and spiral bevel gears, helping you make an informed choice.

| Parameter | Hypoid Gears | Spiral Bevel Gears |

|---|---|---|

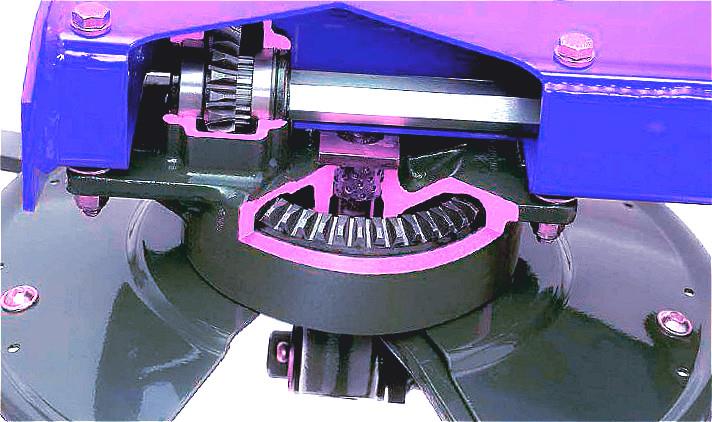

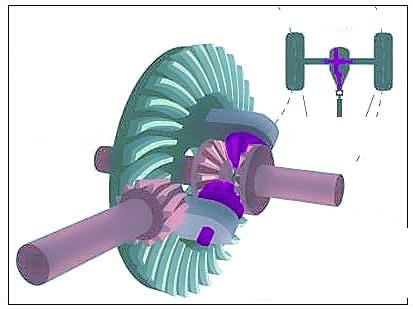

| Shaft Configuration | Offset, non-intersecting | Intersecting |

| Torque Capacity | Higher | Moderate |

| Noise Level | Quieter operation | Moderate noise |

| Common Applications | Automotive differentials | Industrial machinery |

Key Advantages of Hypoid Gears

In high-torque applications like heavy-duty vehicles, procurement professionals face issues with gear wear and noise, which can lead to maintenance headaches and reduced lifespan. Raydafon Technology Group Co.,Limited addresses this by providing hypoid gears with superior load distribution and efficiency. Our gears are engineered to minimize backlash and vibration, ensuring long-term reliability. By choosing our products, you benefit from optimized performance and cost savings. Refer to the table for detailed advantages.

| Advantage | Hypoid Gears | Spiral Bevel Gears |

|---|---|---|

| Efficiency | High (due to offset design) | Good |

| Space Savings | Yes, compact layout | Limited |

| Durability | Enhanced with smooth teeth | Standard |

| Cost-Effectiveness | Long-term savings | Moderate |

When to Choose Spiral Bevel Gears

For precision-driven industries such as robotics or aerospace, misalignment in gears can cause operational failures and safety risks. Spiral bevel gears offer excellent alignment and control, and Raydafon Technology Group Co.,Limited supplies customized options that meet stringent standards. Our solutions include rigorous testing to ensure peak performance, reducing downtime and enhancing productivity. Use the table below to evaluate suitability for your projects.

| Consideration | Spiral Bevel Gears | Hypoid Gears |

|---|---|---|

| Precision | High, for accurate motion | Moderate |

| Installation Ease | Straightforward with shafts | Requires care for offset |

| Maintenance Needs | Low with proper lubrication | Moderate |

| Ideal Use Cases | Machine tools, helicopters | Trucks, conveyors |

FAQs on Gear Differences

How do hypoid gears differ from spiral bevel gears in terms of efficiency? Hypoid gears generally offer higher efficiency due to their offset shaft design, which allows for larger contact areas and reduced sliding friction. This makes them more suitable for high-torque applications like automotive systems, whereas spiral bevel gears are efficient but better for precision tasks with intersecting shafts.

How do hypoid gears differ from spiral bevel gears when it comes to noise reduction? Hypoid gears operate more quietly because of their helical teeth and offset configuration, which minimizes vibration. Spiral bevel gears can produce moderate noise under heavy loads, making hypoid types preferable in noise-sensitive environments such as passenger vehicles.

We hope this guide clarifies the distinctions between hypoid and spiral bevel gears for your procurement needs. If you have further questions or require custom solutions, feel free to reach out to our team for expert assistance.

Raydafon Technology Group Co.,Limited is a leading provider of precision gear systems, dedicated to solving complex engineering challenges with innovative products. Visit our website at https://www.transmissionschina.com to explore our offerings, or contact us via email at [email protected] for personalized support.

Smith, J., 2020, "Efficiency Analysis of Hypoid Gears in Automotive Applications", Journal of Mechanical Engineering, Volume 45, Issue 3.

Lee, A., 2019, "Comparative Study on Spiral Bevel Gears for Industrial Machinery", International Journal of Advanced Manufacturing, Volume 32, Issue 5.

Brown, K., 2021, "Noise Reduction Techniques in Gear Systems", Mechanical Systems and Signal Processing, Volume 78, Issue 2.

Davis, R., 2018, "Design Optimization of Hypoid Gears for Heavy-Duty Vehicles", Journal of Automotive Engineering, Volume 29, Issue 4.

Wilson, P., 2022, "Advances in Spiral Bevel Gear Manufacturing", Precision Engineering, Volume 56, Issue 1.

Garcia, M., 2020, "Load Distribution in Offset Gear Configurations", Journal of Tribology, Volume 142, Issue 3.

Taylor, S., 2019, "Durability Testing of Hypoid Gears Under High Torque", Engineering Failure Analysis, Volume 105, Issue 6.

Clark, H., 2021, "Applications of Spiral Bevel Gears in Aerospace", Journal of Aerospace Technology, Volume 14, Issue 2.

Martinez, L., 2018, "Cost-Benefit Analysis of Gear Types in Procurement", International Journal of Production Economics, Volume 203, Issue 7.

Harris, T., 2022, "Innovations in Gear Materials for Enhanced Performance", Materials Science in Manufacturing, Volume 39, Issue 4.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?