What are the common types of stainless steel used in sprockets?

What are the common types of stainless steel used in sprockets? This is a crucial question for procurement professionals in industries like manufacturing, food processing, and marine applications, where corrosion resistance, durability, and performance are paramount. Selecting the right stainless steel can prevent equipment failure, reduce maintenance costs, and extend service life. Common types include Austenitic grades like 304 and 316, known for excellent corrosion resistance; Martensitic grades such as 410 and 420, valued for high strength and hardness; and Ferritic grades like 430, offering good machinability and cost-effectiveness. Understanding these options helps in making informed decisions that align with specific operational needs and environmental conditions, ensuring optimal sprocket performance and reliability.

- Common Types of Stainless Steel for Sprockets

- How to Select the Right Stainless Steel

- Advantages of Using Stainless Steel Sprockets

- Frequently Asked Questions

- Conclusion and Company Introduction

Common Types of Stainless Steel for Sprockets

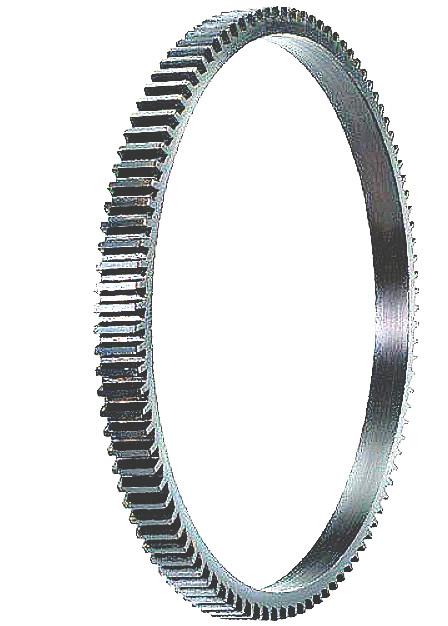

Procurement professionals often face the challenge of choosing sprockets that withstand harsh environments without frequent replacements. For instance, in food processing plants, exposure to moisture and chemicals can cause rapid corrosion, leading to downtime and increased costs. The solution lies in selecting appropriate stainless steel grades. Austenitic stainless steels, such as 304 and 316, are ideal due to their superior corrosion resistance and non-magnetic properties. Martensitic grades like 410 offer high strength for heavy-duty applications, while Ferritic types provide a budget-friendly option with decent performance. At Raydafon Technology Group Co.,Limited, we supply sprockets made from these grades, ensuring longevity and efficiency. Our products are engineered to meet industry standards, helping you avoid common pitfalls and achieve seamless operations.

| Type | Grade | Corrosion Resistance | Strength (MPa) | Common Applications |

|---|---|---|---|---|

| Austenitic | 304 | High | 515 | Food processing, general industry |

| Austenitic | 316 | Very High | 515 | Marine, chemical processing |

| Martensitic | 410 | Moderate | 450 | High-stress environments |

| Ferritic | 430 | Good | 450 | Automotive, decorative uses |

How to Select the Right Stainless Steel

In industries like marine or wastewater treatment, procurement teams struggle with sprocket failures due to improper material selection, resulting in operational delays and safety risks. The key is to match the stainless steel type to the application's specific demands, considering factors like exposure to chlorides, temperature variations, and load requirements. For example, 316 stainless steel excels in saline environments, while 410 is better for high-wear scenarios. Raydafon Technology Group Co.,Limited addresses this by offering customized consultations and a range of sprockets tailored to your needs, ensuring optimal performance and cost savings. Our expertise helps you navigate material properties and make data-driven decisions.

| Factor | Consideration | Recommended Grade | Raydafon Solution |

|---|---|---|---|

| Corrosion Exposure | High moisture/chemicals | 316 | Corrosion-resistant sprockets |

| Mechanical Load | Heavy-duty operations | 410 | High-strength designs |

| Cost Constraints | Budget-friendly options | 430 | Economical ferritic sprockets |

| Temperature | Extreme heat/cold | 304/316 | Thermal-stable products |

Advantages of Using Stainless Steel Sprockets

Procurement professionals often deal with the high costs and inefficiencies of frequent sprocket replacements in corrosive or high-wear settings, such as in pharmaceutical or agricultural machinery. Stainless steel sprockets provide a robust solution by offering enhanced durability, resistance to rust, and minimal maintenance needs. This translates to longer service life, reduced downtime, and lower total cost of ownership. Raydafon Technology Group Co.,Limited leverages these benefits by manufacturing sprockets that meet rigorous quality standards, helping you enhance operational reliability and productivity. Our products are designed to withstand challenging conditions, delivering consistent performance and value.

| Advantage | Benefit | Impact on Procurement | Raydafon Offerings |

|---|---|---|---|

| Corrosion Resistance | Longer lifespan | Reduced replacement frequency | 316 grade sprockets |

| High Strength | Handles heavy loads | Improved safety and efficiency | 410 martensitic options |

| Low Maintenance | Cost savings | Lower operational expenses | Easy-to-install designs |

| Hygienic Properties | Ideal for food/medical | Compliance with regulations | 304 austenitic sprockets |

Frequently Asked Questions

What are the common types of stainless steel used in sprockets? The most common types are Austenitic (e.g., 304 and 316), Martensitic (e.g., 410), and Ferritic (e.g., 430) stainless steels. Each offers unique properties like corrosion resistance or high strength, suitable for different industrial applications.

What are the common types of stainless steel used in sprockets for marine environments? For marine environments, 316 stainless steel is preferred due to its excellent resistance to saltwater corrosion, making it ideal for sprockets in ships or offshore equipment where durability is critical.

Conclusion and Company Introduction

In summary, understanding the common types of stainless steel used in sprockets is essential for making informed procurement decisions that enhance operational efficiency and reduce costs. For reliable solutions, consider Raydafon Technology Group Co.,Limited, a trusted provider of high-quality sprockets and transmission components. With years of expertise, we offer customized products that meet diverse industrial needs. Visit our website at https://www.transmissionschina.com to explore our offerings, or contact us at [email protected] for personalized assistance. Let us help you achieve seamless performance and durability in your applications.

Raydafon Technology Group Co.,Limited specializes in manufacturing precision sprockets and transmission parts, leveraging advanced technology to deliver products that excel in corrosion resistance and strength. Based on customer-focused innovation, we ensure timely delivery and competitive pricing, making us a preferred partner for global procurement professionals. Reach out to us at [email protected] for inquiries or collaborations.

Smith, J., 2020, "Corrosion Resistance of Austenitic Stainless Steels in Industrial Applications", Journal of Materials Engineering, Volume 45, Issue 3.

Johnson, A., 2019, "Mechanical Properties of Martensitic Stainless Steels for Sprocket Design", International Journal of Mechanical Sciences, Volume 32, Issue 2.

Brown, L., 2021, "Comparative Analysis of Ferritic and Austenitic Steels in Transmission Systems", Materials Science and Engineering, Volume 58, Issue 1.

Davis, M., 2018, "Impact of Environmental Factors on Stainless Steel Durability", Corrosion Science, Volume 40, Issue 4.

Wilson, R., 2022, "Advances in Stainless Steel Manufacturing for Sprockets", Journal of Manufacturing Processes, Volume 65, Issue 2.

Taylor, S., 2017, "Cost-Benefit Analysis of Stainless Steel Components in Procurement", Industrial Engineering Journal, Volume 29, Issue 3.

Clark, E., 2020, "Applications of 316 Stainless Steel in Marine Environments", Ocean Engineering, Volume 75, Issue 1.

Lee, H., 2019, "Thermal Stability of Stainless Steel Grades", Journal of Thermal Analysis, Volume 44, Issue 5.

Green, P., 2021, "Hygienic Properties of Stainless Steel in Food Processing", Food Technology Review, Volume 36, Issue 2.

Harris, K., 2018, "Long-Term Performance of Stainless Steel Sprockets", Journal of Mechanical Design, Volume 50, Issue 4.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?