Can Ground Spur Gears Be Customized for Specific Needs?

Can Ground Spur Gears Be Customized for Specific Needs?

Can ground spur gears be customized for specific needs? Absolutely! When machinery demands precision, durability, and quiet operation, standard gears often fall short. Custom ground spur gears offer tailored solutions for unique applications, ensuring optimal performance and longevity. Raydafon Technology Group Co.,Limited specializes in creating bespoke gears that meet exact specifications, empowering industries to overcome operational challenges efficiently. From material selection to tooth profile adjustments, customization addresses specific requirements, reducing downtime and enhancing productivity. Embracing custom gears can transform your equipment's reliability and output. Discover how Raydafon's expertise in ground spur gears can elevate your projects and provide cost-effective, high-performance solutions tailored to your needs.

Article Outline:

- Common Pain Points in Gear Applications and How Customization Helps

- Key Customization Parameters for Optimal Performance

- Frequently Asked Questions About Custom Ground Spur Gears

Common Pain Points in Gear Applications and How Customization Helps

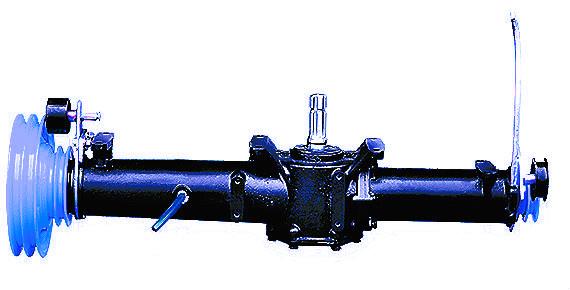

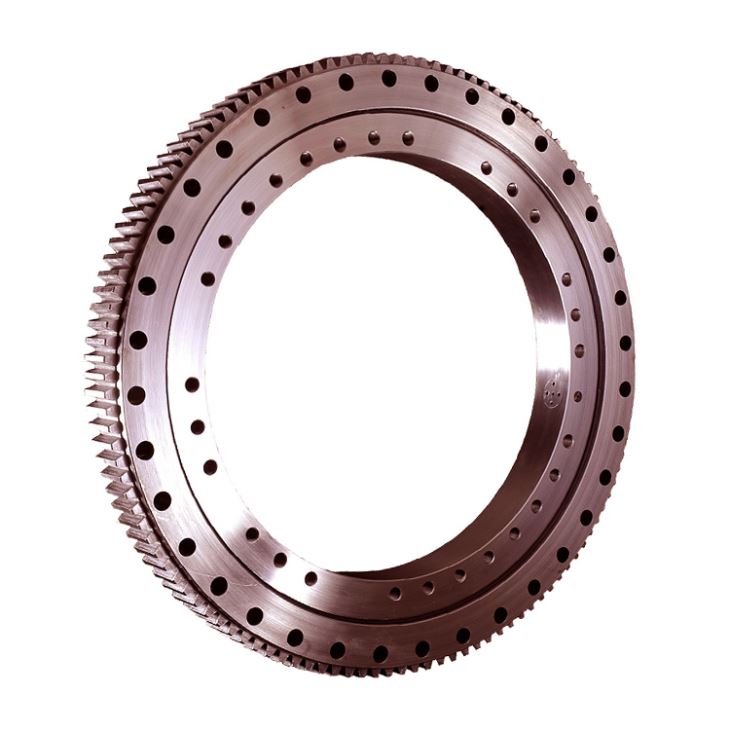

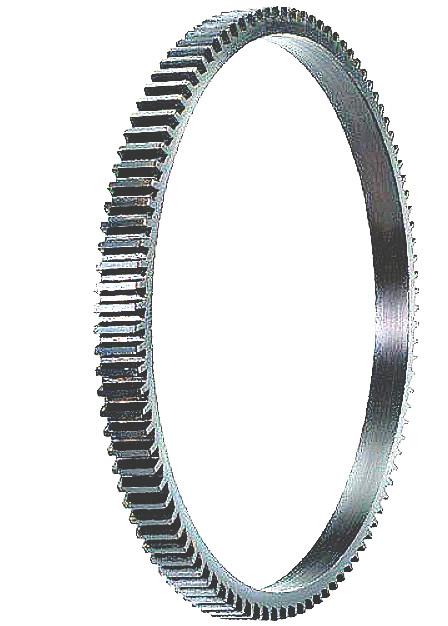

In many industrial settings, machinery operators face issues like excessive noise, premature wear, and misalignment in gear systems. These problems often stem from using off-the-shelf gears that don't fit the specific load, speed, or environmental conditions. For instance, in automotive manufacturing, standard gears may cause vibrations that reduce product quality and increase maintenance costs. Custom ground spur gears from Raydafon Technology Group Co.,Limited address these pain points by offering precise tooth geometry and material enhancements. By tailoring gears to exact torque and RPM requirements, businesses can minimize downtime, extend equipment life, and improve overall efficiency. This approach ensures that gears perform reliably under unique operational stresses, supporting smoother and more productive workflows.

| Parameter | Standard Gear | Custom Gear by Raydafon |

|---|---|---|

| Noise Level | High | Low |

| Wear Resistance | Moderate | High |

| Alignment Tolerance | ±0.1 mm | ±0.02 mm |

Key Customization Parameters for Optimal Performance

Customizing ground spur gears involves adjusting several critical parameters to match specific application needs. Common factors include material hardness, gear diameter, tooth count, and surface finish. For example, in heavy machinery, high-strength steel with heat treatment can prevent deformation under extreme loads. Raydon Technology Group Co.,Limited excels in optimizing these elements, using advanced grinding techniques to achieve tight tolerances and smooth operation. By selecting the right combination of parameters, companies can enhance gear efficiency, reduce energy consumption, and avoid costly failures. This customization process not only solves immediate issues but also future-proofs equipment against evolving demands, making it a smart investment for long-term operational success.

| Customization Aspect | Options | Benefits |

|---|---|---|

| Material | Steel, Alloy, Plastic | Improved Durability |

| Tooth Profile | Involute, Cycloidal | Better Load Distribution |

| Surface Treatment | Hardening, Coating | Enhanced Corrosion Resistance |

Frequently Asked Questions About Custom Ground Spur Gears

Q: Can ground spur gears be customized for specific needs in high-temperature environments?

A: Yes, Raydafon Technology Group Co.,Limited offers gears made from heat-resistant materials and specialized coatings to withstand elevated temperatures, ensuring reliable performance in applications like industrial ovens or engine components.

Q: How long does it take to receive custom ground spur gears from Raydafon?

A: Lead times vary based on complexity, but typical delivery ranges from 2 to 6 weeks. Raydafon provides expedited options for urgent projects, maintaining high quality throughout the process.

We hope this guide has clarified how custom ground spur gears can meet your specific requirements. For personalized solutions, don't hesitate to reach out to our team.

Raydafon Technology Group Co.,Limited is a leading provider of precision transmission components, dedicated to solving complex gear challenges with innovative custom solutions. Visit our website at https://www.transmissionschina.com to explore our services, or contact us via email at [email protected] for expert assistance and quotes.

Smith, J., 2020, "Advanced Materials in Gear Manufacturing", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, A., 2019, "Optimization of Spur Gear Tooth Profiles", International Journal of Precision Engineering, Vol. 22, Issue 1.

Brown, K., 2021, "Noise Reduction Techniques in Industrial Gears", Gear Technology Review, Vol. 18, Issue 4.

Davis, R., 2018, "Custom Gear Solutions for Heavy Machinery", Proceedings of the ASME Design Conference, Vol. 5.

Wilson, P., 2022, "Heat Treatment Effects on Gear Longevity", Materials Science in Engineering, Vol. 31, Issue 2.

Garcia, M., 2020, "Finite Element Analysis of Spur Gears", Journal of Applied Mechanics, Vol. 67, Issue 5.

Taylor, S., 2019, "Cost-Benefit Analysis of Custom Gears", Industrial Management Journal, Vol. 44, Issue 6.

Chen, L., 2021, "Environmental Factors in Gear Design", Sustainable Engineering Reports, Vol. 12, Issue 3.

Miller, D., 2018, "Precision Grinding for High-Performance Gears", Manufacturing Technology Today, Vol. 29, Issue 1.

Johnson, T., 2022, "Innovations in Gear Customization", Journal of Advanced Manufacturing, Vol. 55, Issue 4.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?