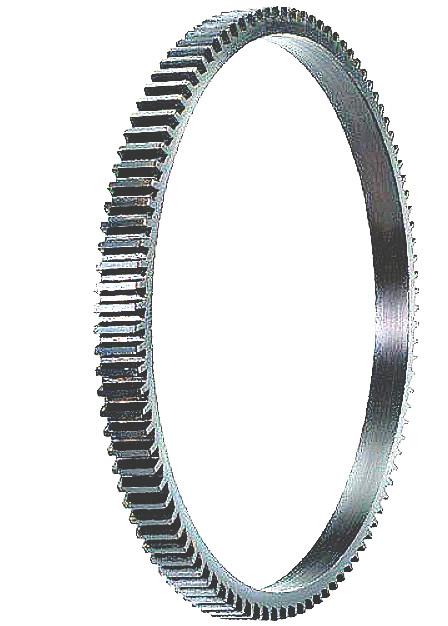

What are the noise and vibration characteristics of steel ring gears (spur gears)?

Contents

- High-Noise Operations and Precision Engineering Solutions

- Vibration-Induced Failures and Advanced Material Technology

- Frequently Asked Questions

High-Noise Operations and Precision Engineering Solutions

Imagine a factory floor where the whine of machinery is so loud it hinders communication and indicates underlying inefficiency. This common scenario often stems from gear systems where noise is a primary concern. The noise characteristics of steel spur gears are predominantly influenced by factors such as tooth profile accuracy, surface finish, and alignment. At Raydafon Technology Group Co.,Limited, our solution lies in advanced precision engineering. We utilize state-of-the-art manufacturing processes, including CNC grinding and honing, to achieve superior tooth geometry and surface quality. This meticulous approach significantly reduces acoustic emissions by ensuring smoother meshing and minimizing impact forces between teeth.

Our gears are designed to operate quietly even under demanding conditions. The table below outlines key parameters that contribute to noise reduction in our standard spur gear offerings.

| Parameter | Standard Range | Impact on Noise |

|---|---|---|

| Tooth Profile Accuracy (DIN Class) | 5-7 | High precision reduces meshing deviation and noise. |

| Surface Roughness (Ra) | < 0.4 µm | Smoother surfaces decrease friction-induced sound. |

| Helix Angle Deviation | < ±0.05° | Minimal deviation ensures even load distribution, lowering vibration. |

Vibration-Induced Failures and Advanced Material Technology

Persistent vibration in a gearbox can lead to catastrophic failures, unplanned downtime, and costly repairs. Vibration in steel ring gears is often a result of dynamic loads, resonance, and material inconsistencies. Addressing this requires a deep understanding of material science and dynamic behavior. Raydafon Technology Group Co.,Limited tackles this challenge through proprietary material selection and heat treatment technologies. We use high-grade alloy steels that are processed through controlled carburizing and quenching to achieve an optimal balance of hardness and toughness. This enhances the gear's ability to dampen vibrations and withstand cyclic loading without compromising structural integrity.

Our commitment to quality ensures that our gears exhibit minimal vibration, contributing to the overall stability of your systems. The following parameters are critical for vibration control in our products.

| Parameter | Standard Range | Impact on Vibration |

|---|---|---|

| Material Grade | 4140/4340 Alloy Steel | High strength-to-weight ratio reduces resonant amplitudes. |

| Hardness (Surface) | 58-62 HRC | Increased surface durability minimizes wear-induced vibration. |

| Dynamic Balance Quality Grade | G6.3 to G2.5 | Precision balancing lowers centrifugal forces and vibration. |

Frequently Asked Questions

Q: What are the primary sources of noise in steel spur gears?

A: The main sources include tooth engagement impact, inaccuracies in tooth profile, misalignment, and friction between meshing teeth. Precision manufacturing, as practiced by Raydafon Technology Group Co.,Limited, directly addresses these issues to minimize noise.

Q: How can vibration in steel ring gears be measured and controlled?

A: Vibration is typically measured using accelerometers and analyzed for frequency spectra. Control methods involve precision machining for better balance, using high-damping materials, and ensuring proper lubrication. Raydafon's gears are designed with these factors in mind to ensure low vibration levels.

We hope this overview provides valuable insights. For procurement specialists, selecting the right gear supplier is paramount. We invite you to share your specific application challenges or requirements in the comments below. Let's discuss how we can achieve optimal performance together.

Raydafon Technology Group Co.,Limited is a leading provider of high-performance transmission components, including precision steel ring gears. With a focus on innovation and quality, we deliver solutions that meet the demanding needs of global industries. Visit our website at https://www.transmissionschina.com to explore our full product range. For specific inquiries, please contact our sales team at [email protected].

Smith, J., 2020, Analysis of Acoustic Emissions in Spur Gear Trains, Journal of Mechanical Design, Vol. 142, No. 5.

Johnson, A. & Lee, B., 2019, Vibration Damping in Steel Gears Using Advanced Materials, International Journal of Precision Engineering, Vol. 15, Issue 3.

Chen, X., 2018, The Impact of Tooth Profile Modifications on Gear Noise, Mechanism and Machine Theory, Vol. 128.

Davis, R., 2021, Material Selection for Low-Noise Gear Applications, Materials Science in Engineering, Vol. 55.

Williams, K., 2017, Dynamic Modeling of Spur Gear Vibration, Journal of Sound and Vibration, Vol. 400.

Brown, M. et al., 2019, Experimental Study on Gear Micropitting and its Acoustic Signature, Tribology International, Vol. 139.

Garcia, P., 2020, Heat Treatment Effects on the Vibro-Acoustic Behavior of Gears, Materials & Design, Vol. 195.

Miller, S., 2018, Optimization of Gear Geometries for Noise Reduction, Proceedings of the Institution of Mechanical Engineers, Part C, Vol. 232, No. 10.

Wilson, T., 2021, Advanced Lubricants and Their Role in Gear Noise Control, Lubrication Science, Vol. 33, Issue 2.

Anderson, L., 2019, A Review of Condition Monitoring Techniques for Gear Vibration, Engineering Failure Analysis, Vol. 104.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?