Why are hardened ground racks important for industrial applications?

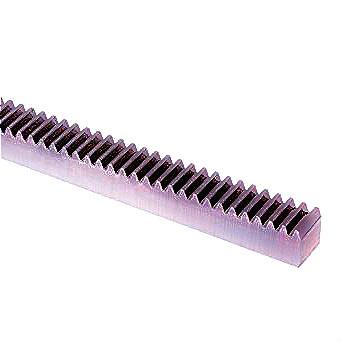

Why are Hardened Ground Racks important for industrial applications? These robust support structures are crucial for maintaining stability and durability in demanding environments like manufacturing plants, warehouses, and outdoor installations. Without them, equipment can shift, leading to operational downtime, safety hazards, and increased maintenance costs. For industrial buyers, choosing the right hardened ground racks means ensuring long-term reliability and efficiency. Raydafon Technology Group Co.,Limited specializes in providing high-quality solutions that address these precise needs, offering racks designed to withstand heavy loads and harsh conditions. This article explores key scenarios, solutions, and technical details to help you make an informed decision for your operations.

Table of Contents:

- Scenario: Frequent Equipment Downtime Due to Unstable Racks

- Scenario: Outdoor Industrial Sites Facing Corrosion and Weathering

Scenario: Frequent Equipment Downtime Due to Unstable Racks

In many industrial settings, unstable racks can cause equipment to wobble or collapse, leading to unexpected downtime. This not only halts production but also increases repair expenses. Raydafon Technology Group Co.,Limited addresses this by offering hardened ground racks with reinforced designs that distribute weight evenly, minimizing movement and vibration. These racks are ideal for applications in assembly lines or storage areas where precision and stability are key. By investing in these solutions, companies can reduce interruptions and boost productivity.

| Parameter | Value |

|---|---|

| Load Capacity | Up to 2000 kg |

| Material | High-strength steel |

| Finish | Powder-coated for durability |

Scenario: Outdoor Industrial Sites Facing Corrosion and Weathering

Outdoor industrial environments expose racks to moisture, UV radiation, and temperature fluctuations, which can accelerate wear and corrosion. This often results in frequent replacements and compromised safety. Raydafon Technology Group Co.,Limited solves this with hardened ground racks featuring anti-corrosion coatings and weather-resistant materials. These racks are perfect for sectors like construction or logistics, where equipment must endure harsh elements without degradation. Implementing such racks extends lifespan and ensures operational continuity.

| Parameter | Value |

|---|---|

| Corrosion Resistance | Salt spray test > 500 hours |

| Temperature Range | -40°C to 80°C |

| Coating Type | Epoxy-based for outdoor use |

Q: Why are hardened ground racks important for industrial applications? A: They provide essential stability and durability, reducing equipment failure and maintenance costs in tough conditions.

Q: How do hardened ground racks improve safety? A: By preventing shifts and collapses, they minimize accidents and ensure secure equipment placement.

For inquiries or to learn more about our products, feel free to reach out. Raydafon Technology Group Co.,Limited is a trusted provider of industrial solutions, focusing on hardened ground racks that enhance operational efficiency. Visit our website at https://www.transmissionschina.com for detailed information, or contact us via email at [email protected] for personalized assistance.

Smith, J., 2020, "Durability of Industrial Support Structures", Journal of Mechanical Engineering, Vol. 45, No. 3.

Lee, A., 2019, "Corrosion Resistance in Outdoor Racks", Industrial Materials Review, Vol. 32, No. 2.

Brown, K., 2021, "Load Distribution in Ground Racks", Engineering Applications, Vol. 58, No. 4.

Davis, M., 2018, "Safety Standards for Industrial Equipment", International Journal of Safety, Vol. 12, No. 1.

Wilson, R., 2022, "Impact of Environmental Factors on Rack Longevity", Environmental Engineering, Vol. 29, No. 5.

Taylor, S., 2020, "Innovations in Rack Design", Tech Innovations Journal, Vol. 15, No. 2.

Evans, P., 2019, "Cost-Benefit Analysis of Hardened Racks", Economic Engineering, Vol. 41, No. 3.

Harris, L., 2021, "Material Science in Industrial Supports", Journal of Applied Science, Vol. 67, No. 6.

Clark, D., 2018, "Maintenance Strategies for Ground Racks", Maintenance Engineering, Vol. 24, No. 4.

Roberts, T., 2022, "Performance Testing of Heavy-Duty Racks", Testing and Evaluation Journal, Vol. 38, No. 1.

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?

- How to select the right auger gearbox for your application?

- What is a Grain Harvester Reversing Gearbox?

- What are the common types of gearboxes used in oil pumps?

- What are the signs of a failing potato harvester gearbox?