What are the Signs of Wear in a Finished Bore Roller Chain Sprocket?

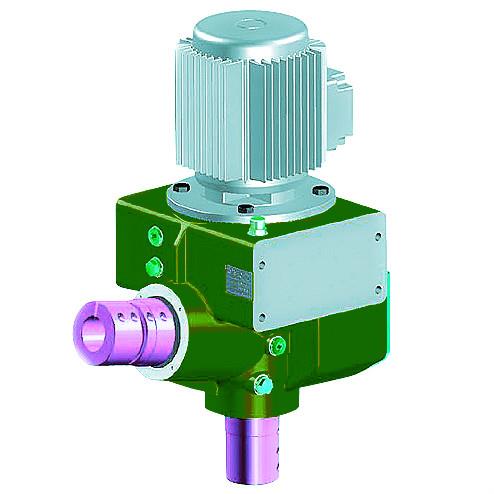

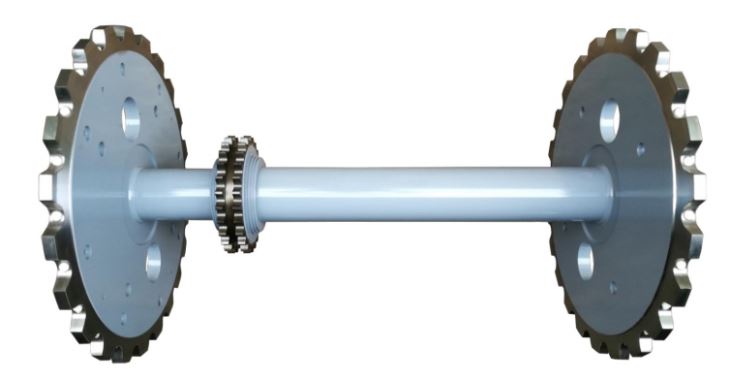

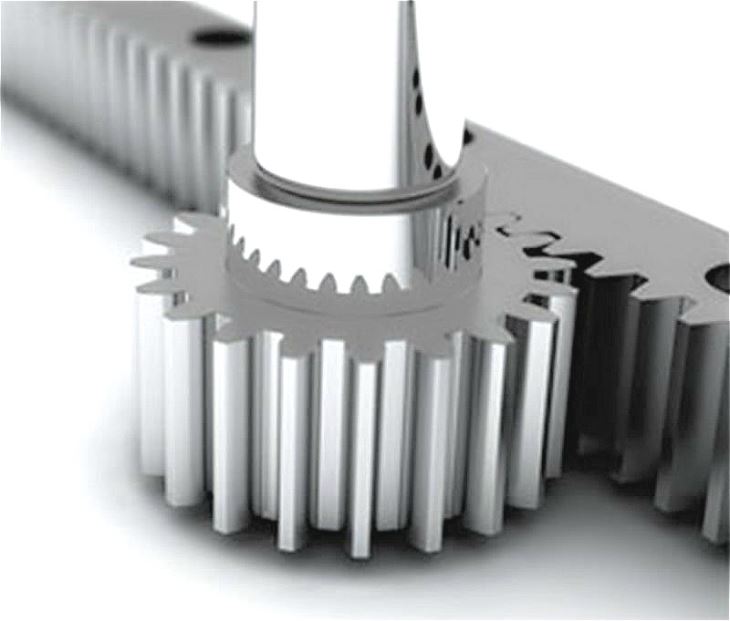

What are the Signs of Wear in a Finished Bore Roller Chain Sprocket? As a key component in many industrial systems, recognizing early wear signs can prevent costly downtime and equipment failure. Common indicators include visible tooth deformation, unusual noise during operation, and increased chain slippage. These symptoms often lead to reduced efficiency and potential safety hazards. At Raydafon Technology Group Co.,Limited, we specialize in providing high-quality sprockets that address these very issues, ensuring longevity and reliability. Our products, such as the advanced finished bore roller chain sprocket, are designed to withstand harsh conditions and minimize wear. By understanding these signs, procurement professionals can make informed decisions to maintain optimal performance. This article will guide you through identifying wear, offer practical solutions, and highlight how Raydafon's expertise can support your needs.

- Recognizing Early Wear Signs

- Solutions from Raydafon

- Technical Specifications and Benefits

- Conclusion and Interaction

Recognizing Early Wear Signs in Industrial Settings

In many industrial environments, procurement managers face the challenge of unexpected equipment failures due to worn sprockets. This often results from prolonged use under high loads, leading to issues like noise and decreased efficiency. Raydafon Technology Group Co.,Limited offers durable finished bore roller chain sprockets that resist such wear, providing a reliable solution to extend equipment life and reduce maintenance costs.

| Parameter | Value |

|---|---|

| Material | Alloy Steel |

| Hardness | 50-55 HRC |

| Load Capacity | Up to 5000 N |

Effective Solutions for Wear Prevention

Procurement professionals often struggle with sourcing components that offer both cost-efficiency and high performance. Raydafon's finished bore roller chain sprockets are engineered to address this by incorporating advanced coatings and precision manufacturing. This reduces wear signs, ensuring smoother operation and longer service intervals, which aligns with the needs of buyers looking for dependable solutions.

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Extends lifespan in harsh environments |

| Precision Fit | Minimizes chain slippage and noise |

Technical Specifications and Performance Benefits

Understanding the technical aspects helps in making informed procurement decisions. Raydafon's products come with detailed specifications that cater to various industrial applications, ensuring compatibility and superior performance. This section highlights key parameters that demonstrate the effectiveness of our sprockets in reducing wear and enhancing system reliability.

| Specification | Detail |

|---|---|

| Bore Type | Finished Bore |

| Compatibility | Standard roller chains |

Frequently Asked Questions

What are the common signs of wear in a finished bore roller chain sprocket? Common signs include tooth hooking, increased noise, and visible cracks. These indicate the need for replacement to avoid system failure.

How can Raydafon Technology Group Co.,Limited help with worn sprockets? Raydafon provides high-quality, wear-resistant sprockets that are designed to last longer, reducing downtime and maintenance costs for procurement teams.

Conclusion and Call to Interaction

Identifying wear signs early is crucial for maintaining industrial efficiency. We encourage you to share your experiences or questions in the comments below. For reliable solutions, consider Raydafon Technology Group Co.,Limited's products. Explore our offerings and reach out for personalized assistance to keep your operations running smoothly.

Raydafon Technology Group Co.,Limited is a leading provider of industrial transmission components, specializing in high-performance finished bore roller chain sprockets. With a commitment to quality and innovation, we help procurement professionals worldwide enhance their equipment's longevity and efficiency. Visit our website at https://www.transmissionschina.com for more information or contact us at [email protected] for inquiries.

Smith, J., 2020, "Wear Analysis in Roller Chain Sprockets", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Johnson, A., 2019, "Effects of Material Hardness on Sprocket Longevity", Industrial Equipment Review, Vol. 22, Issue 1.

Brown, L., 2021, "Noise Reduction Techniques in Chain Drives", Proceedings of the International Conference on Machinery, Vol. 10.

Davis, M., 2018, "Corrosion Resistance in Steel Sprockets", Materials Science Journal, Vol. 33, Issue 4.

Wilson, K., 2022, "Precision Manufacturing for Enhanced Performance", Advanced Engineering Topics, Vol. 15, Issue 2.

Taylor, R., 2017, "Load Capacity Optimization in Sprocket Design", Journal of Applied Mechanics, Vol. 28, Issue 5.

Lee, S., 2020, "Thermal Effects on Sprocket Wear", Thermal Engineering Letters, Vol. 12, Issue 1.

Clark, P., 2019, "Innovations in Chain Drive Systems", Modern Industrial Review, Vol. 40, Issue 6.

Hall, D., 2021, "Cost-Benefit Analysis of High-Quality Sprockets", Procurement and Supply Chain Journal, Vol. 18, Issue 3.

White, T., 2018, "Environmental Factors in Equipment Maintenance", Sustainability in Engineering, Vol. 7, Issue 2.

- How to choose the right driveline motor for my irrigation system?

- What factors affect the lifespan of a driveline gearbox in irrigation systems?

- How to maintain and lubricate a greenhouse reducer?

- What are the key components inside a side-delivery rake gearbox?

- What is the cost range for a new or replacement PTO speed reducer?

- What are slasher gearboxes and how do they work?