Blog

30 2026-01

30 2026-01 How to maintain and lubricate a greenhouse reducer?

A brief guide on the essential steps and best practices for maintaining and lubricating a greenhouse reducer to ensure optimal performance and longevity.

29 2026-01

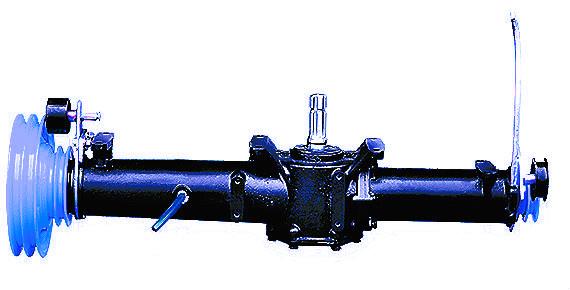

29 2026-01 What are the key components inside a side-delivery rake gearbox?

An introduction to the main parts and their functions within a side-delivery rake gearbox.

22 2026-01

22 2026-01 What is the cost range for a new or replacement PTO speed reducer?

A brief overview of the pricing factors and typical cost range for new or replacement PTO speed reducers.

21 2026-01

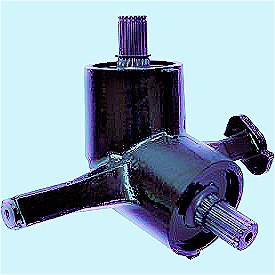

21 2026-01 What are slasher gearboxes and how do they work?

Slasher gearboxes are specialized transmission units designed for high-performance applications, enhancing power delivery and durability in demanding machinery.

14 2026-01

14 2026-01 How to select the right auger gearbox for your application?

Selecting the right auger gearbox is crucial for optimal performance and efficiency in material handling applications. This guide outlines key factors to consider, including torque requirements, speed ratios, and environmental conditions.

13 2026-01

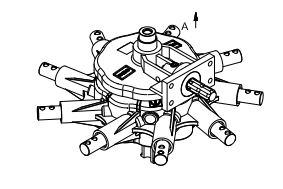

13 2026-01 What is a Grain Harvester Reversing Gearbox?

A grain harvester reversing gearbox is a mechanical device that enables the harvester to move in reverse, facilitating maneuvering and unloading during harvesting operations.