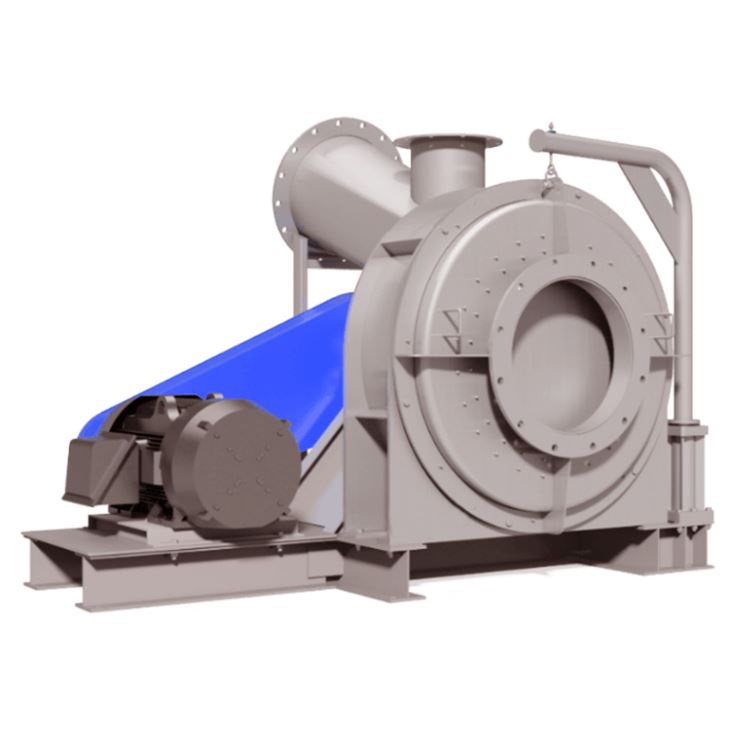

Air Compressors

We manufacture air compressors designed to deliver high-efficiency, low-maintenance compressed air for industrial, commercial, and specialty applications. With decades of expertise in power transmission and fluid dynamics, our compressors are engineered to optimize energy use, reduce downtime, and meet the stringent demands of modern manufacturing. Let us help you upgrade your pneumatic systems with cutting-edge technology.

Product Classification

We categorize our air compressors to simplify your procurement process:

-

By Technology

- Reciprocating (Piston) Compressors: Ideal for small-scale, intermittent use.

- Rotary Screw Compressors: Continuous-duty performance for factories and workshops.

- Centrifugal Compressors: High-flow, oil-free solutions for power plants and chemical plants.

-

By Lubrication

- Oil-Injected: Cost-effective, general-purpose use.

- Oil-Free: Certified for food-grade, medical, and electronics manufacturing.

-

By Application

- Industrial: Automation, CNC machinery, assembly lines.

- Commercial: Auto shops, dry cleaners, dental clinics.

- Specialty: Underwater breathing, HVAC, and aerospace testing.

Product Introduction

Why choose Raydafon air compressors?

Air compressors convert power into potential energy by compressing air, which is then used to operate tools, machinery, and processes. Our designs prioritize energy efficiency, reliability, and low noise, making them ideal for 24/7 operations where uptime and cost control are critical.

Key Design Principles:

- Efficiency: Variable Speed Drives (VSD) reduce energy consumption by up to 35%.

- Durability: Stainless steel and corrosion-resistant components for longevity.

- Safety: ATEX-certified models for hazardous environments.

Product Features

1. Energy Efficiency

- VSD Technology: Matches air output to demand, slashing energy costs.

- Heat Recovery Systems: Reuse waste heat for workshop heating or water preheating.

2. Reliability

- Low-Maintenance Design: Oil-free models eliminate costly filtration and disposal.

- Smart Controls: IoT-enabled monitoring for predictive maintenance.

3. Customization

- Tailored Solutions: Adjust pressure, flow rate, and footprint to your facility.

- Certified Engineering: Our ISO-certified team designs compressors for your exact needs.

4. Certifications & Standards

- ISO 9001 (Quality Management)

- CE Marking (EU Safety Compliance)

- ATEX Certification (Explosive Atmospheres)

- Class 0 Oil-Free (ISO 8573-1)

Product Advantages

1. Cost Savings

- 35% Lower Energy Bills: VSD technology pays for itself in 2–3 years.

- Zero Oil Contamination: Oil-free models avoid product recalls and rework.

2. Global Support Network

- 24/7 Engineering Assistance: Our ISO-certified team supports you in 28 countries.

- JIT Delivery: Three regional hubs ensure 3–6 week lead times for bulk orders.

3. Sustainability

- Carbon-Neutral Options: Solar-compatible models for green manufacturing.

- 95% Recyclable: Designed for eco-friendly disposal.

Application Areas

| Industry | Use Case | Why Procure Raydafon? |

|---|---|---|

| Automotive | Paint spraying, tire inflation, assembly tools | VSD technology, 24/7 reliability |

| Food & Beverage | Bottling, packaging, fermentation | Class 0 oil-free, ATEX-certified |

| Medical | Ventilators, dental tools, lab equipment | Ultra-clean air, whisper-quiet operation |

| Construction | Jackhammers, nail guns, concrete finishing | Portable, diesel-driven models |

Frequently Asked Questions (FAQs)

Q1: Can Raydafon compressors handle intermittent use?

Yes. Our reciprocating compressors are ideal for small-scale, on-demand applications.

Q2: What is the minimum order quantity (MOQ) for custom compressors?

Flexible MOQs start at 5 units, with vendor-managed inventory for bulk buyers.

Q3: How do Raydafon compressors reduce energy costs?

VSD technology adjusts output to demand, cutting bills by up to 35%.

Q4: Do you offer predictive maintenance for compressor systems?

Yes. SmartDrive IoT monitors vibration, temperature, and oil quality in real time.

Q5: Are Raydafon compressors compatible with third-party pneumatic tools?

Yes. Universal designs ensure compatibility while offering 40%+ durability gains over market averages.

Technical Specifications

| Parameter | Details |

|---|---|

| Technology | Reciprocating, rotary screw, centrifugal |

| Pressure Range | 5–50 bar (customizable) |

| Flow Rate | 0.5–100 m³/min |

| Certifications | ISO 9001, CE, ATEX, Class 0 Oil-Free |

- View as

Air Compressor For Medical Industry

Air Compressor For Organic Fertilizer Production

Air Compressor For Production Of Chemical Raw Materials

Air Compressor For Tire Production Equipment

Laser Cutting Air Compressor